Light-cured urethane acrylate aqueous dispersion and preparation method thereof

A polyurethane acrylate and acrylate technology, applied in the field of coatings, can solve the problems of unsustainable antifouling performance, elastic hand feel of water-based light-curable resin and anti-fouling and anti-graffiti properties can not be obtained at the same time, and the paint film is easy to produce adhesion and other problems. Fingerprint performance is maintained for a long time, the effect of improving stain resistance and graffiti resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

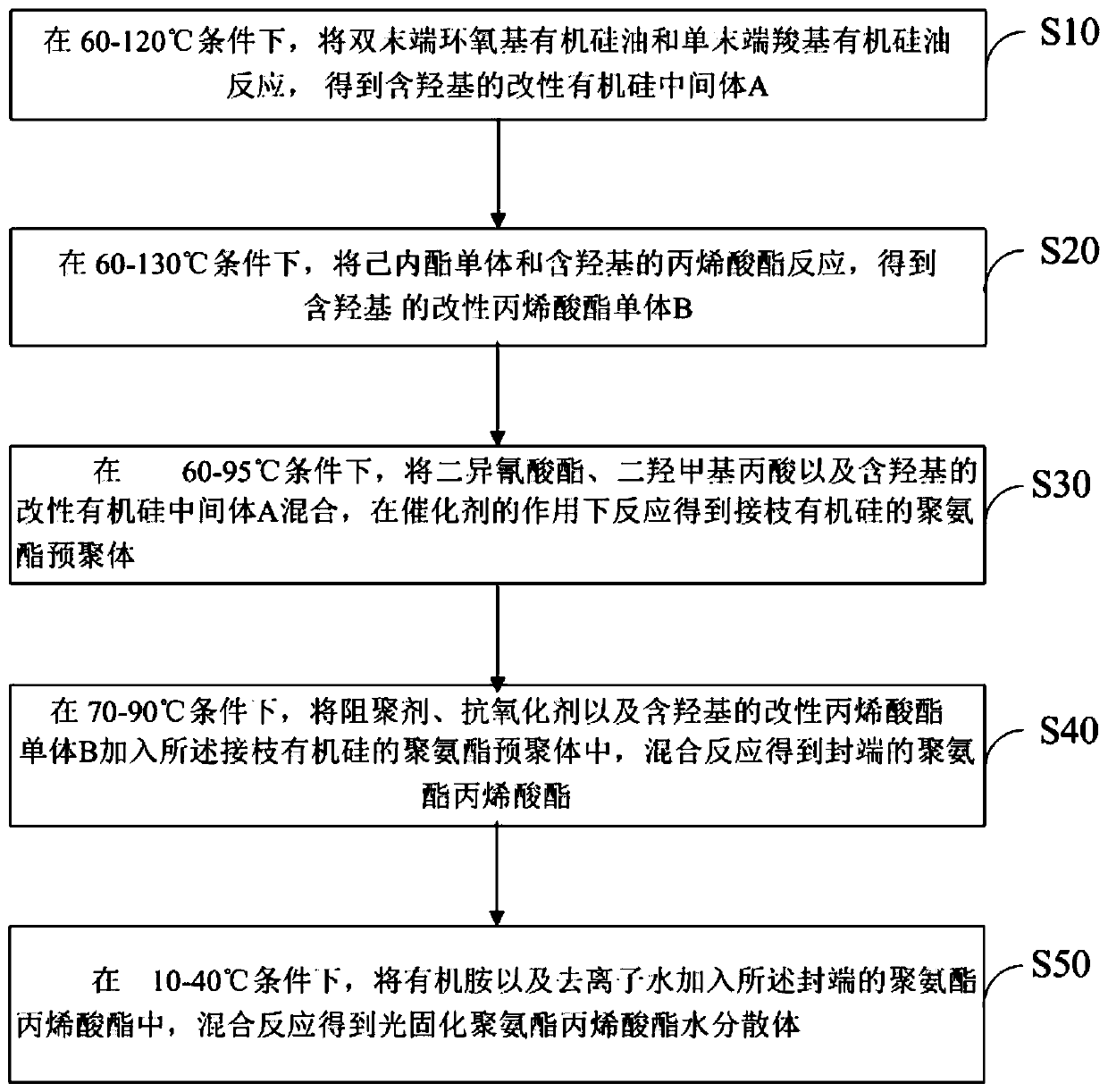

[0030] see figure 1 , figure 1 It is a flowchart of a preferred embodiment of a method for preparing a light-cured polyurethane acrylate aqueous dispersion of the present invention, wherein, as shown in the figure, it includes the following steps:

[0031] S100, under the condition of 60-120°C, reacting double-end epoxy silicone oil and single-end carboxyl silicone oil to obtain a modified silicone intermediate A containing hydroxyl;

[0032] S200, under the condition of 60-130°C, reacting caprolactone monomer and hydroxyl-containing acrylate to obtain hydroxyl-containing modified acrylate monomer B;

[0033] S300, under the condition of 60-95°C, mix diisocyanate, dimethylolpropionic acid, and hydroxyl-containing modified silicone intermediate A, and react under the action of a catalyst to obtain a polyurethane prepolymer grafted with silicone;

[0034] S400, under the condition of 70-90°C, add a polymerization inhibitor, an antioxidant, and a modified acrylate monomer B con...

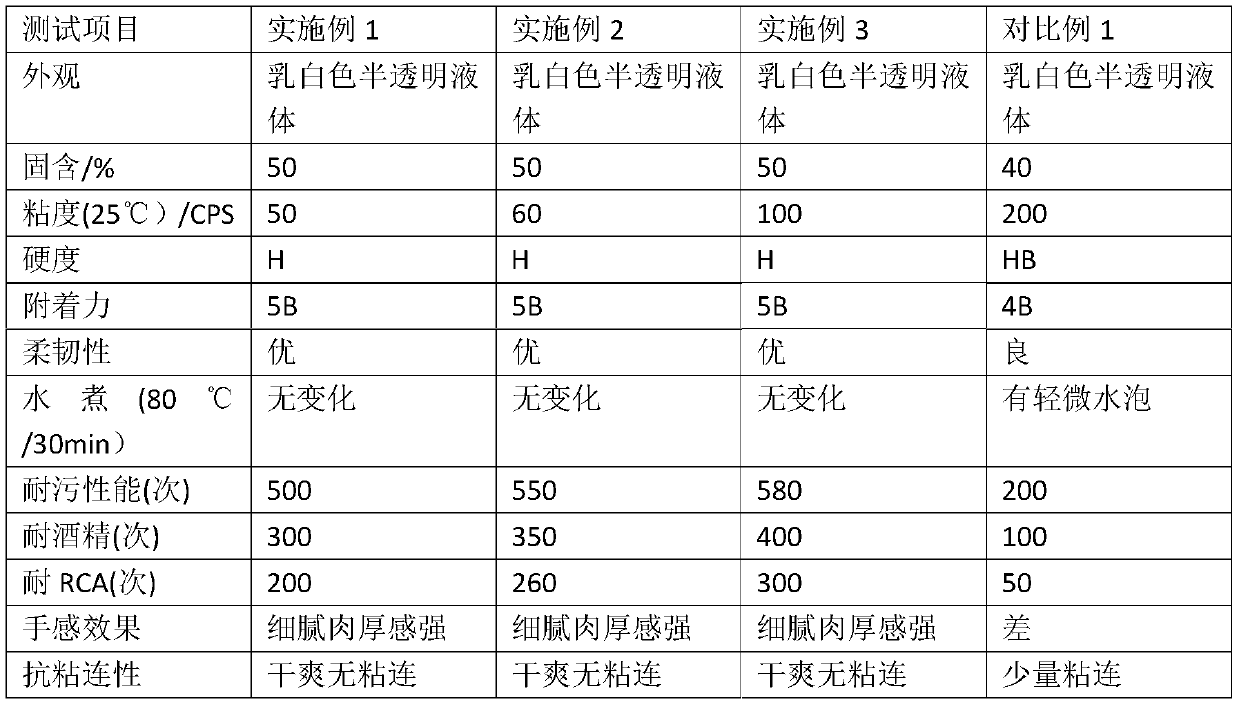

Embodiment 1

[0060] 1), Synthesis of modified organosilicon intermediate A containing hydroxyl

[0061] Add 130g of double-end epoxy silicone oil X-22-163 (Shin-Etsu) and 280g of single-end carboxyl silicone oil X-22-3701E (Shin-Etsu) into a dry four-necked flask equipped with a stirrer, a thermometer, and a condenser, and add 1.25g of catalyst triphenylphosphine, the reaction is carried out in an electric heating mantle with temperature control, the temperature is raised to 105°C, and the reaction is maintained at this temperature for about 4 hours to obtain the modified organosilicon intermediate A containing hydroxyl groups.

[0062] 2), the synthesis of modified acrylate monomer B containing hydroxyl

[0063] Add 114g caprolactone monomer and 298g ditrimethylolpropane triacrylate in the dry four-necked flask that stirrer, thermometer, condenser are equipped with, add dropwise 1.25g catalyst dibutyltin dilaurate, react in with Carried out in a temperature-controlled electric heating ma...

Embodiment 2

[0073] 1), Synthesis of modified organosilicon intermediate A containing hydroxyl

[0074] Add 135g of double-end epoxy silicone oil KF-105 (Shin-Etsu) and 267g of single-end carboxyl silicone oil X-22-3701E (Shin-Etsu) into a dry four-necked flask equipped with a stirrer, thermometer, and condenser, and add 1.25g The catalyst is triphenylphosphine, and the reaction is carried out in an electric heating mantle with temperature control. The temperature is raised to 105° C., and the reaction is maintained at this temperature for about 4 hours to obtain a hydroxyl-containing organosilicon intermediate A.

[0075] 2), the synthesis of modified acrylate monomer B containing hydroxyl

[0076] Add 114g caprolactone monomer and 297g pentaerythritol triacrylate (PETA) in the dry four-necked flask that agitator, thermometer, condenser are equipped with, add dropwise 1.25g catalyst dibutyltin dilaurate, react in with temperature control It was carried out in an electric heating mantle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com