Transparent substrate having reinforced surfaces and method for manufacturing same

A transparent substrate, surface enhancement technology, applied in chemical instruments and methods, other household appliances, electronic equipment, etc., can solve the problems of reduced productivity, low surface hardness, complex process, etc., to improve surface hardness and improve fingerprint resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] [Example 1] Production of Coating Composition Containing Copolymers 1 and 9

[0183] Regarding the synthesis procedure, successive hydrolysis and condensation were performed step by step as follows.

Embodiment 1-a

[0184] [Example 1-a] Catalyst Production

[0185] In order to adjust the basicity, a 10% by weight potassium hydroxide (KOH) aqueous solution was mixed with a 25% by weight tetramethylammonium hydroxide (TMAH) aqueous solution to prepare a catalyst 1a.

Embodiment 1-b

[0186] [Example 1-b] Synthesis of linear silsesquioxane structure

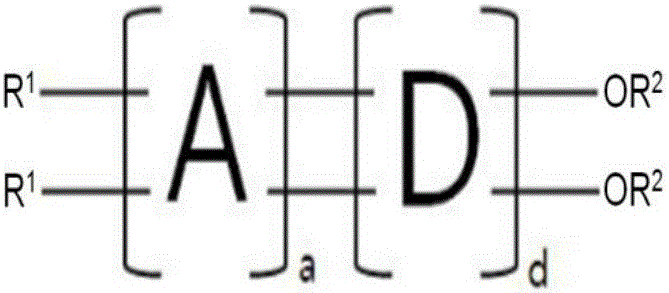

[0187] In a drying flask equipped with a condenser tube and a stirrer, 1 weight part of the catalyst produced in 5 parts by weight of distilled water, 15 parts by weight of tetrahydrofuran, and 1 part by weight of the catalyst produced in the above-mentioned embodiment 1-a was added dropwise, and after stirring at normal temperature for 1 hour, 2-( 20 parts by weight of 3,4-epoxycyclohexyl)ethyltrimethoxysilane, and 15 parts by weight of tetrahydrofuran were added dropwise again, followed by further stirring for 5 hours. Take the mixed solution under stirring, remove the catalyst and impurities by washing twice, and filter it. It can be confirmed by IR analysis that the SI-OH functional group generated at the end group (3200cm -1 ), as a result of measuring the molecular weight, it was confirmed that silsesquioxane having a linear structure such as the chemical formula 4 structure had a molecular weight of 8,000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com