Antireflection film, polarizing plate, and image display device

An anti-reflection film, reactive technology, used in polarizing elements, chemical instruments and methods, electronic equipment, etc., can solve the problems of reducing sufficient refractive index and insufficient hardness of the low-refractive index layer, and achieve excellent surface hardness and uniformity. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0165] (Preparation of composition (1) for hard coat layer)

[0166] The components shown below were mixed to prepare a composition (1) for a hard coat layer.

[0167] 10 parts by mass of reactive silica fine particles (Z7537, manufactured by JSR Corporation, 50% of solid content, 60% of reactive silica fine particles)

[0168] 5.7 parts by mass of urethane acrylate (UV1700B, manufactured by Nippon Gosei Co., 10 functions)

[0169] 0.6 parts by mass of polymerization initiator (Irgacure 184; manufactured by BASF Corporation)

[0170] 3.3 parts by mass of methyl ethyl ketone

[0171] 2.3 parts by mass of methyl isobutyl ketone

[0172] In addition, the solid content mass ratio of the leveling agent in the composition (1) for hard coats was 0.10%.

[0173] (Preparation of composition (2) for hard coat layer)

[0174] The components shown below were mixed to prepare a composition (2) for a hard coat layer.

[0175] 5 parts by mass of polyester acrylate (Aronix M-9050, manuf...

Embodiment 1

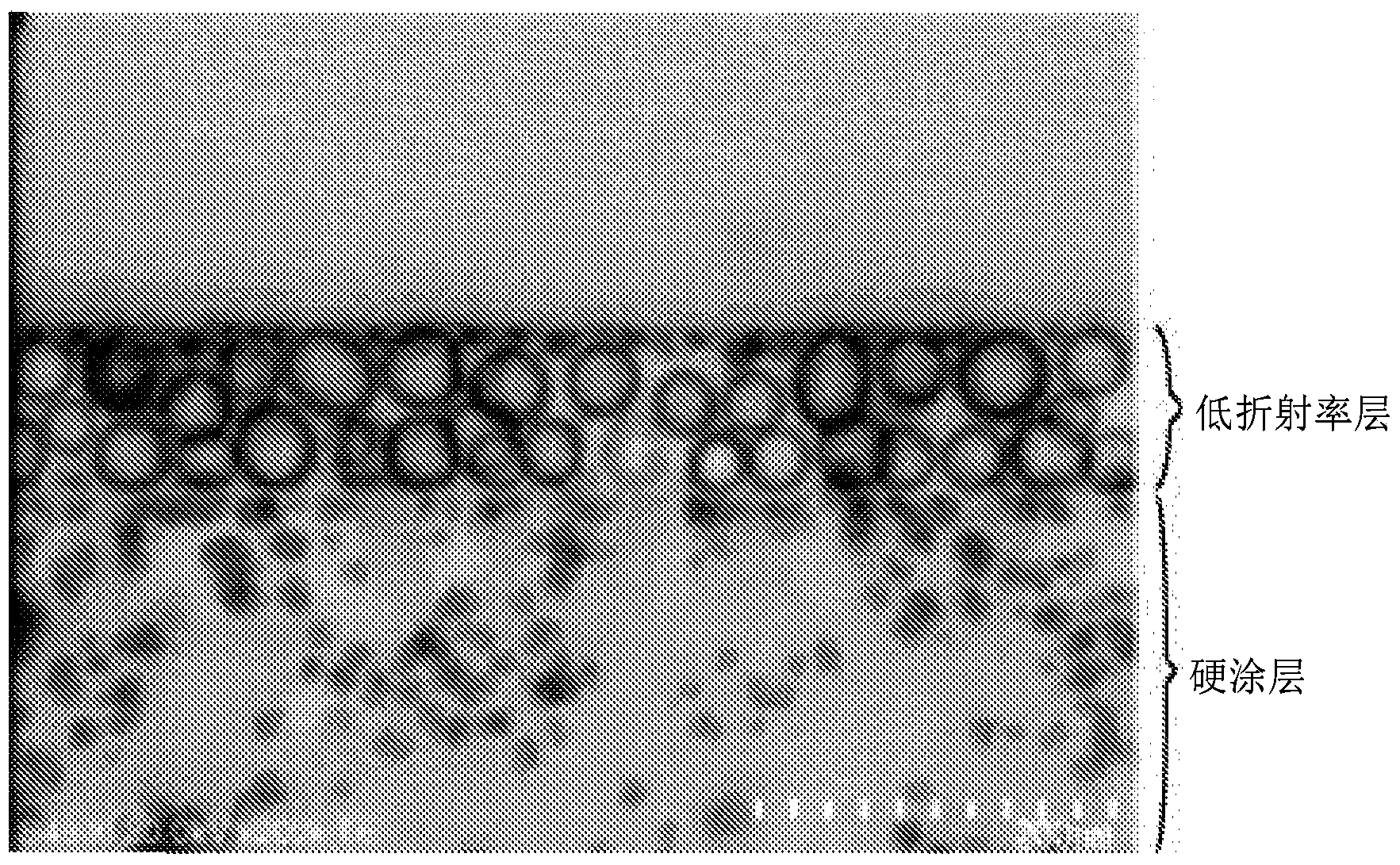

[0301] Wet weight 30g / m on one side of cellulose triacetate film (thickness 80μm) 2 (dry weight 15g / m 2 ) to coat the composition (1) for a hard coat layer. Dry at 50°C for 30 seconds and irradiate at 50mJ / cm 2 UV rays, forming a hard coat.

[0302] Next, the composition (1) for low-refractive-index layers was apply|coated so that the film thickness after drying (25 degreeC*30 second-70 degreeC*30 second) might become 0.1 micrometer on the hard-coat layer formed. And using an ultraviolet irradiation device (manufactured by Fusion UV Systems Japan, light source H bulb), with a radiation dose of 192mJ / m 2 It was irradiated with ultraviolet rays and cured to obtain an antireflection film. The film thickness was adjusted so that the minimum value of the reflectance was located near the wavelength of 550 nm.

[0303] In the low refractive index layer of the obtained antireflection film, the compounding ratio of hollow silica particles to (meth)acrylic resin (content of hollow ...

Embodiment 2

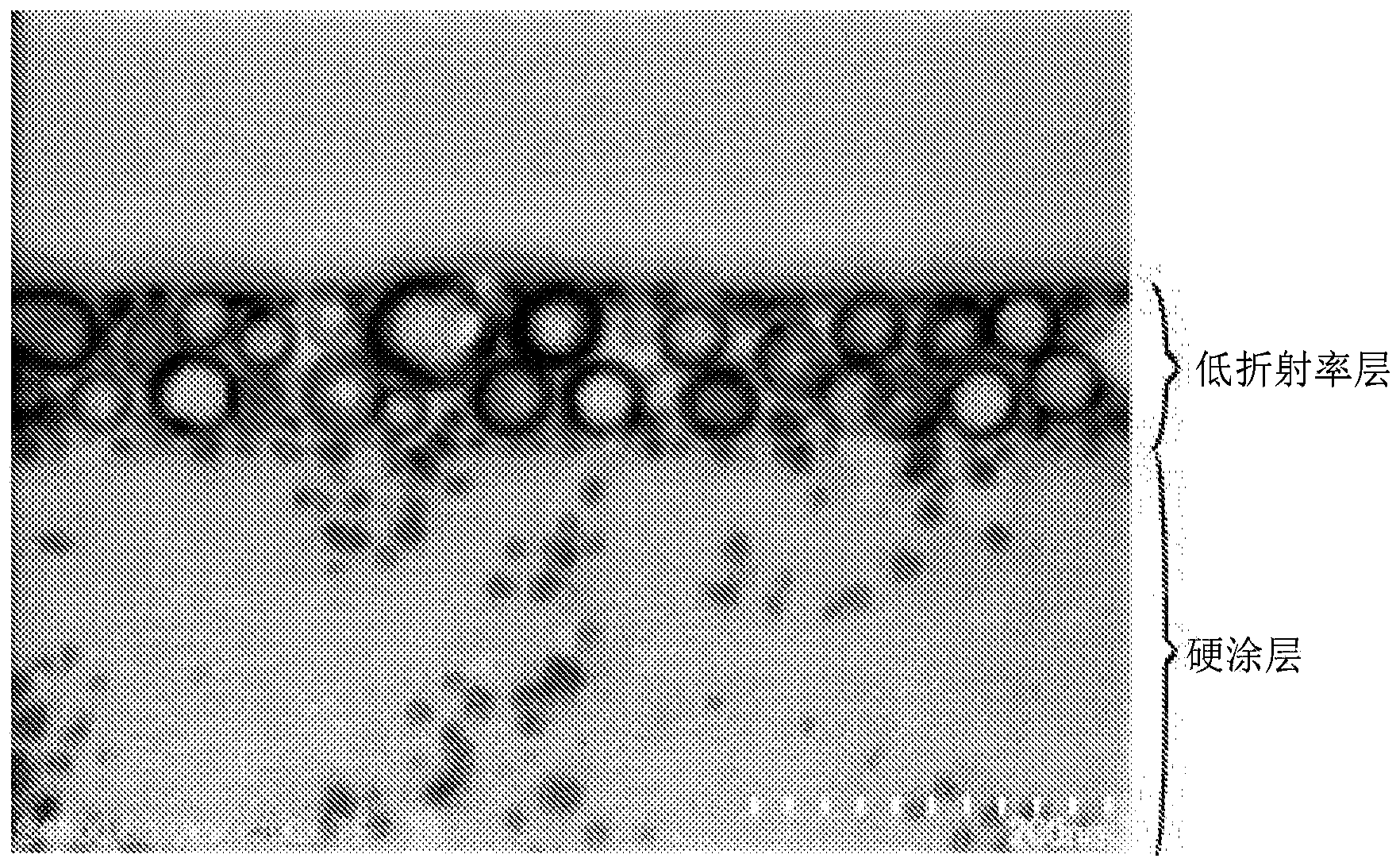

[0305] An antireflection film was obtained in the same manner as in Example 1, except that the composition for a low-refractive index layer (1) was used instead of the composition for a low-refractive index layer (2).

[0306] In the low refractive index layer of the obtained antireflection film, the compounding ratio of hollow silica particles to (meth)acrylic resin (content of hollow silica particles / content of (meth)acrylic resin) is: 1.60.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com