Non-composite release film protective film for silver mirror glass laser cutting

A glass laser and protective film technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that cannot be completely removed, polluted scars, and difficult to remove, so as to reduce the line width of the heat-affected zone and protect Effects of gasification smoke and dust, combustion and melting, and improvement of fingerprint resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

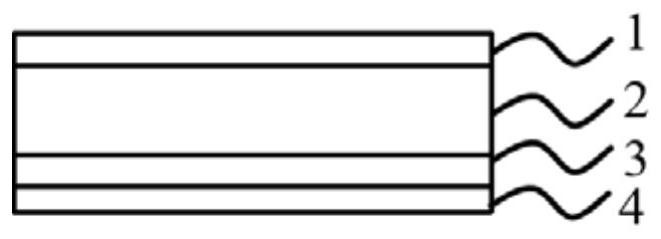

[0042] A kind of non-composite release film is used for the preparation method of the protective film of silver mirror glass laser cutting, comprises the following steps:

[0043] Preparation of the adhesive layer: by weight, 2.2 parts of acrylic acid, 6.5 parts of butyl acrylate, 3.5 parts of lauryl alcohol methacrylate, 2.5 parts of methyl methacrylate, 2 parts of hydroxyethyl methacrylate, 3 parts of methyl Oxymethyl methacrylate, 5 parts of isoprene rubber containing double bonds, and 55 parts of solvent (including 15 parts of acetone, 20 parts of toluene and 20 parts of ethyl ester) were placed in a reaction vessel, and the temperature was raised to 75°C with constant stirring Then, mix 0.25 parts of BPO initiator with the remaining solvent and slowly drop them into the above-mentioned reaction vessel, stir continuously, and continue to react for 3 hours while keeping the reaction temperature constant, and cool to room temperature to obtain acrylate pressure. Sensitive gl...

Embodiment 2

[0048] A kind of non-composite release film is used for the preparation method of the protective film of laser cutting of silver mirror glass, other steps are identical with embodiment 1, and different from embodiment 1 are:

[0049] Preparation of the adhesive layer: by weight, 3.6 parts of acrylic acid, 6.5 parts of butyl acrylate, 4.5 parts of lauryl alcohol methacrylate, 3.2 parts of methyl methacrylate, 2.5 parts of hydroxyethyl methacrylate, 3.5 parts of methyl Oxymethyl methacrylate, 6 parts of isoprene rubber containing double bonds, and 60 parts of solvent (including 15 parts of acetone, 25 parts of toluene and 20 parts of ethyl ester) are placed in a reaction vessel, and the temperature is raised to 80 °C with constant stirring Then, mix 0.45 parts of BPO initiator with the remaining solvent and slowly drop them into the above-mentioned reaction vessel, stir continuously, and continue to react for 3 hours while keeping the reaction temperature constant, and cool to ro...

Embodiment 3

[0051] A kind of non-composite release film is used for the preparation method of the protective film of laser cutting of silver mirror glass, other steps are identical with embodiment 2, and different from embodiment 2 are:

[0052] Preparation of silicone resin layer: 90 parts of hydroxyl-terminated dimethylvinyl (siloxane and polysiloxane), 3.5 parts of hydrogen-terminated poly(dimethylsiloxane), 1 part of modified silane The joint agent was diluted in 230 parts of toluene to obtain a silica gel emulsion, which was coated on the surface of the adhesive layer by the coating bar coating method, and dried at 80°C for 20 minutes until the water evaporated completely to obtain a silicone resin layer, wherein the silicone resin layer The thickness is 2.6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com