Passivating solution for plated metal

A passivation solution and post-passivation technology, applied in the direction of metal material coating process, etc., can solve the problems of different directions and failure to provide, and achieve low cost, environmental protection, high temperature resistance and enhanced fingerprint resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

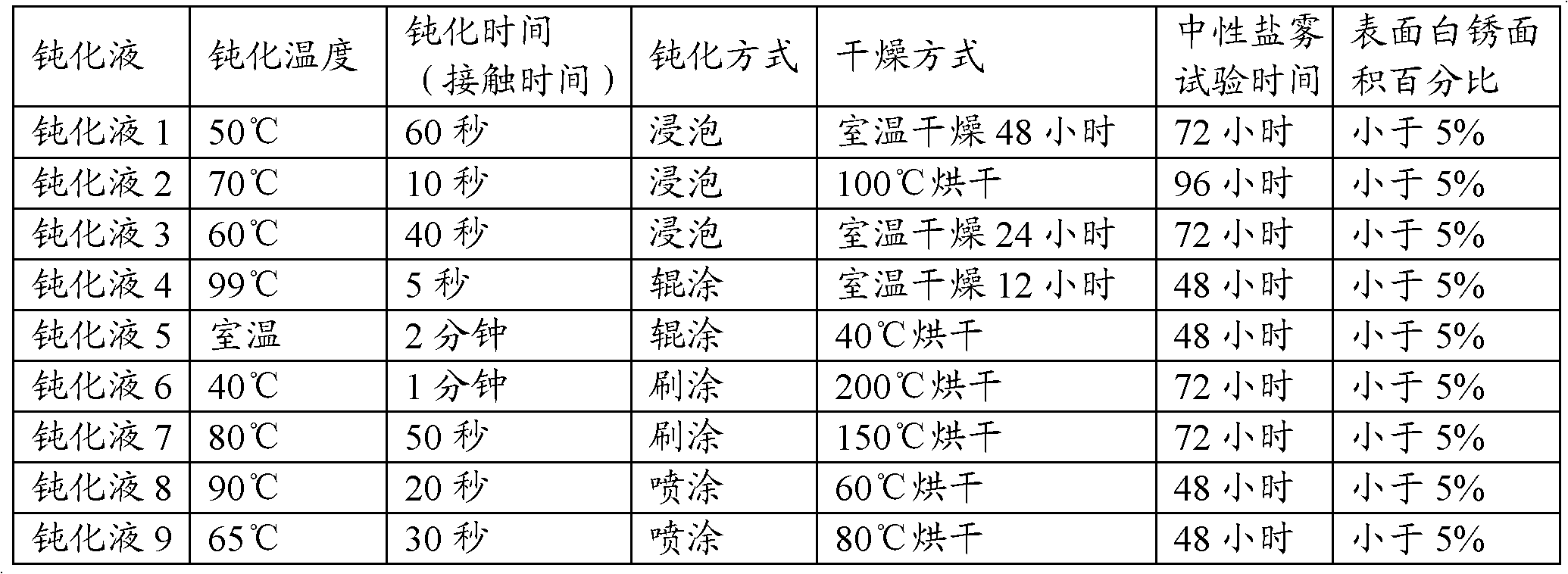

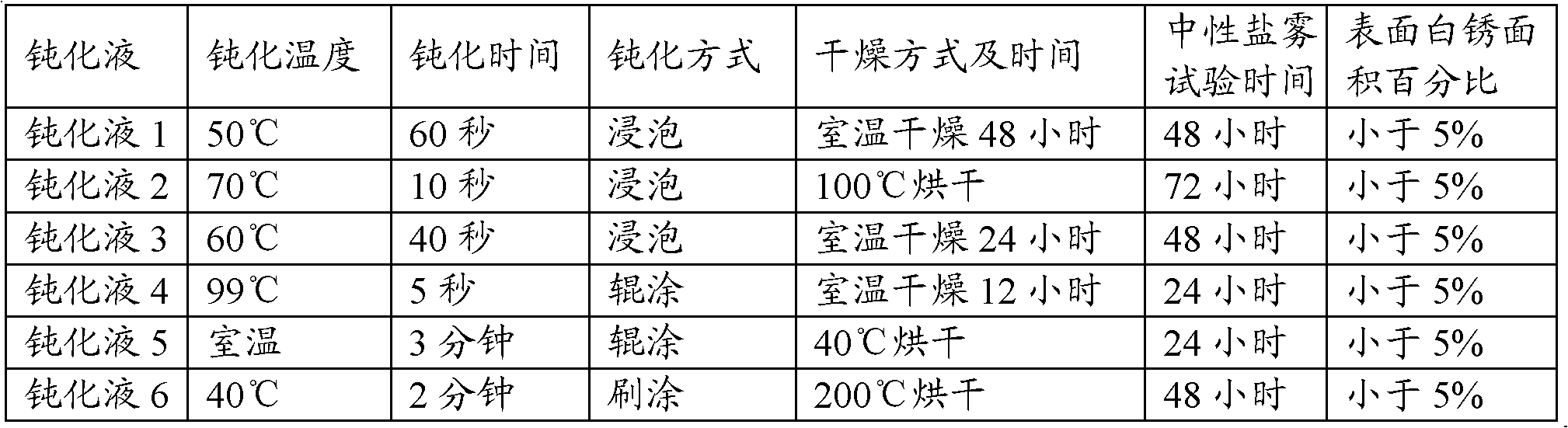

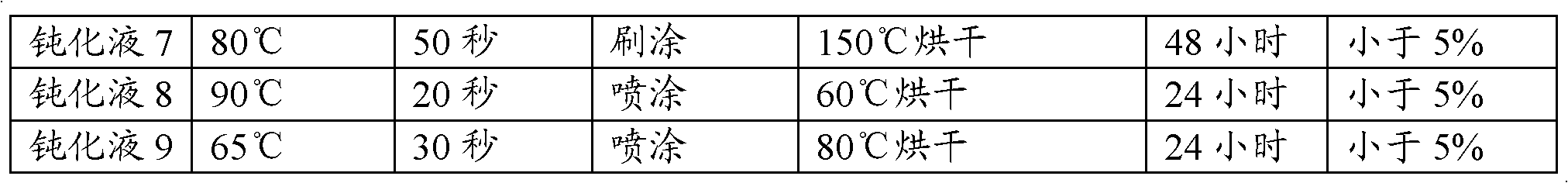

Embodiment 1

[0055] Use deionized water to prepare passivation with ammonium vanadate concentration of 0.01g / L, ammonium molybdate concentration of 5g / L, 3-aminopropyltriethoxysilane concentration of 15g / L, and phytic acid concentration of 60g / L Liquid, adjust its pH to 3 to obtain passivation liquid 1.

Embodiment 2

[0057] Use deionized water to prepare a passivated with a vanadium sodium salt concentration of 0.5g / L, ammonium molybdate concentration of 5g / L, butyl-aminopropyltriethoxysilane concentration of 9g / L, and phytic acid concentration of 30g / L. And adjust the pH to 6 to obtain passivation solution 2.

Embodiment 3

[0059] Prepared with deionized water, the concentration of ammonium vanadate is 5g / L, the concentration of sodium molybdate is 8g / L, the concentration of 3-glycidyl ether propyltrimethoxysilane is 2g / L, and the concentration of epoxy water-based resin is 50g / L. The passivation solution has a pH of 6, and the passivation solution 3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com