Conductive precoated aluminum alloy sheet

A kind of aluminum alloy plate, conductivity technology, applied in the direction of coating, pretreatment surface, metal layered products, etc., can solve problems such as trouble with charged electrons, achieve strong waterproofness, improve conductivity, and inhibit the reduction of adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0091] In this example, examples and comparative examples related to the conductive precoated aluminum alloy sheet of the present invention will be described.

[0092] In this example, the composition of the chemical conversion film and the resin coating film were changed, and as the product of the present invention, 18 types of conductive precoated aluminum alloy sheets (sample E1 to sample E18), as comparative products, 15 types of conductive precoated aluminum alloy sheets (sample C1 to sample C15) as shown in Table 3 described later were produced, and various performance evaluation tests were performed.

[0093] Hereinafter, this will be described in detail.

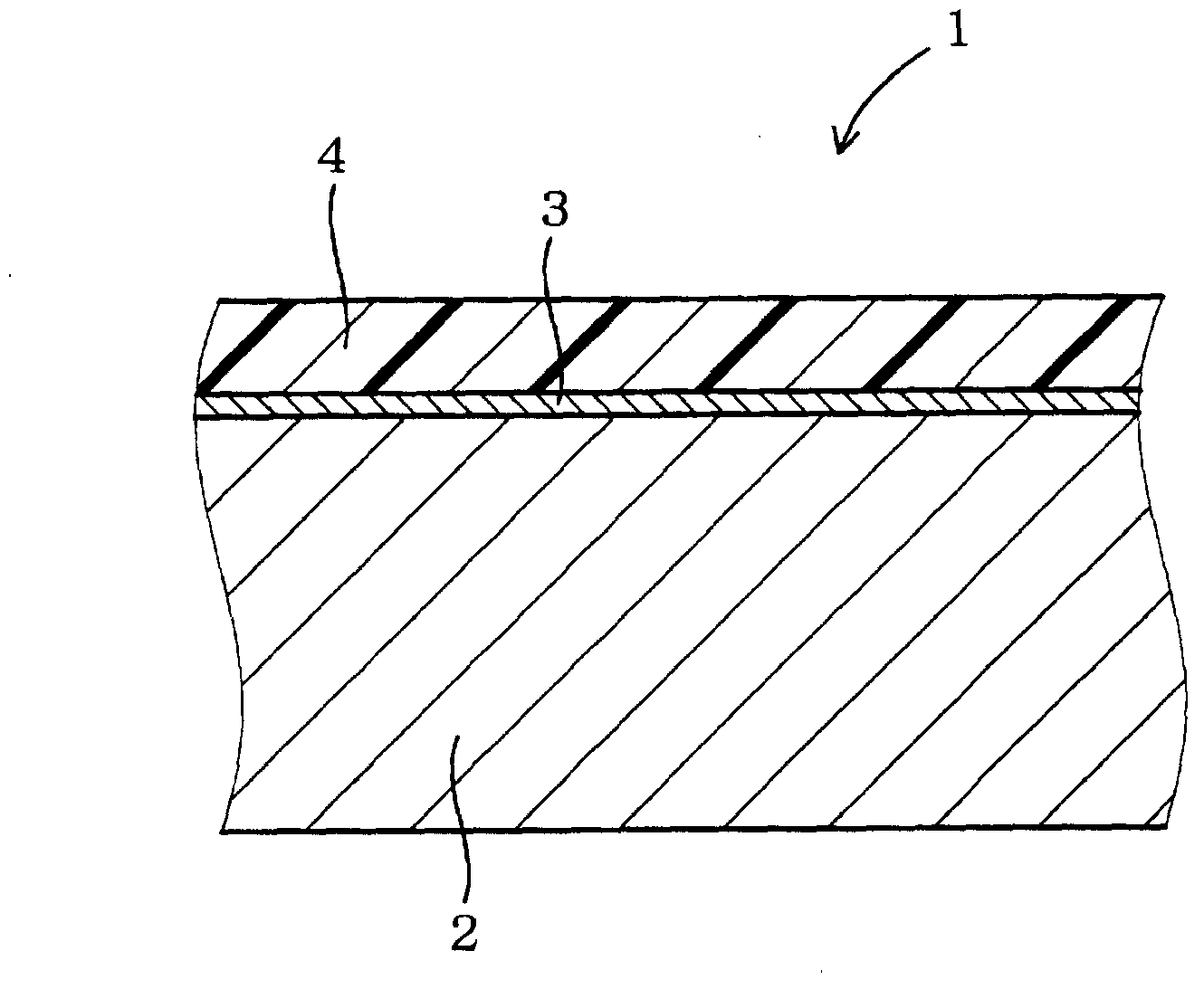

[0094] Conductive pre-coated aluminum alloy plate 1 of sample E1~sample E18 figure 1 As shown, all include a substrate 2 made of an aluminum alloy plate, a chemical conversion film 3 formed on one or both surfaces of the substrate 2 , and a resin coating film 4 formed on the chemical conversion film 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com