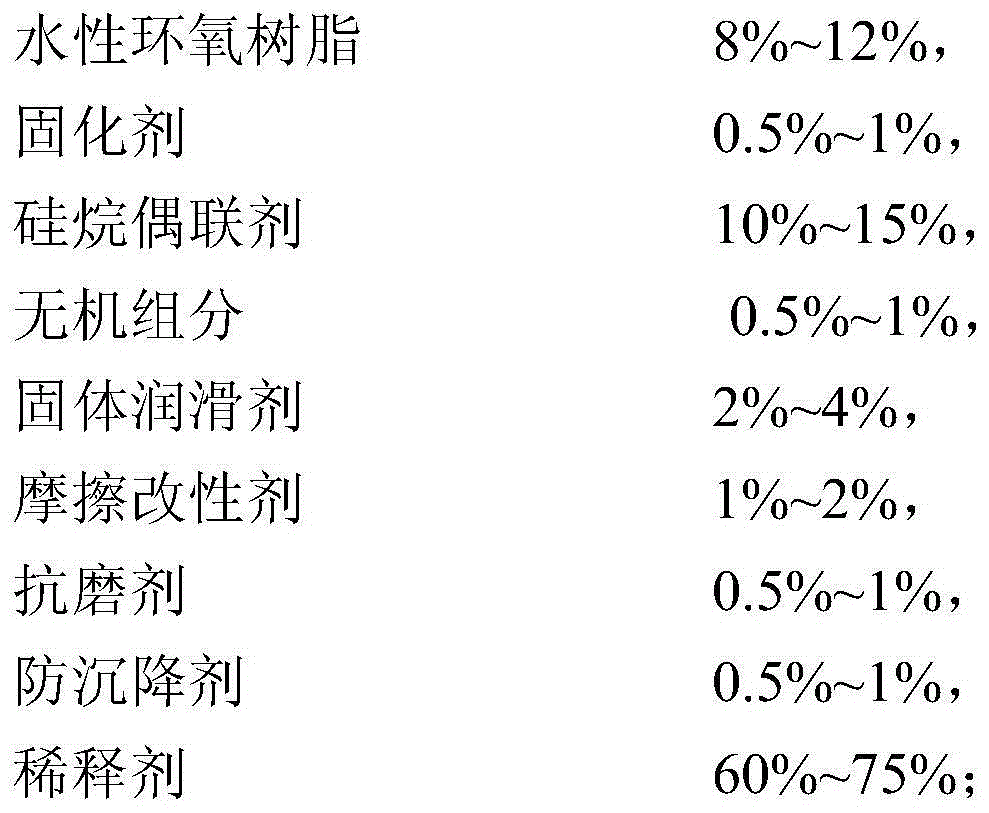

Chromium-free self-lubricating passivation solution and preparation method thereof

A self-lubricating and passivating liquid technology, used in the fields of metallurgy and chemistry, it can solve problems such as unsatisfactory, low friction of galvanized sheet, anti-oxidation, anti-wear, extreme pressure, corrosion resistance and fingerprint resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Component Mass parts

[0038] Water-based epoxy resin 10%

[0039] Curing agent 1%

[0040] Silane coupling agent KH550 10%

[0041] Ce(NO 3 ) 3 1%

[0042] Polyethylene wax 2%

[0043] Oxymolybdenum Dialkyl Dithiophosphate 2%

[0044] Nano silica 1%

[0045] Attapulgite 1%

[0046] Ethanol 12%

[0047] water 60%

[0048] First weigh 1g of curing agent and add it to 10g of water-based epoxy resin, and stir on a magnetic stirrer for 2h, weigh 1g of Ce(NO 3 ) 3 Add to 10g of silane coupling agent KH550, and add 2~3 drops of hydrogen peroxide, put it on a magnetic stirrer and stir for 2-3h, add the above-mentioned stirred water-based epoxy resin and silane coupling agent into 60g of water; Weigh 2g of polyethylene wax and 2g of dialkyldithiooxymolybdenum and add it to 12g of ethanol for ultrasonic dispersion for 30min, stir on a mechanical stirrer for 60min, and add 1g of attapulgite and 1g of ...

Embodiment 2

[0050] Component Mass parts

[0051] Water-based epoxy resin 10%

[0052] Curing agent 1%

[0053] Silane coupling agent KH792 15%

[0054] Ce(NO 3 ) 3 0.5%

[0056] Polyethylene wax 4%

[0057] Oxymolybdenum Dialkyl Dithiophosphate 2%

[0058] Nano silica 1%

[0059] Attapulgite 1%

[0060] Ethanol 10%

[0061] water 55%

[0062] Take by weighing 1g of curing agent and join in the water-based epoxy resin of 10g, and be placed on the magnetic stirrer and stir for 2h, take by weighing 0.5g of Ce(NO 3 ) 3 Add 0.5g of sodium molybdate to 15g of silane coupling agent 792, add 1~2 drops of hydrogen peroxide, stir on a magnetic stirrer for 2-3h, mix the above-mentioned stirred water-based epoxy resin and silane coupling agent Add KH792 to 55g of water and stir; weigh 4g of polyethylene wax and 2g of dialkyldithiooxymolybdenum, add it to 10g of ethanol and ultrasonicall...

Embodiment 3

[0064] Component Mass parts

[0065] Water-based epoxy resin 10%

[0066] Curing agent 1%

[0067] Silane coupling agent KH902 10%

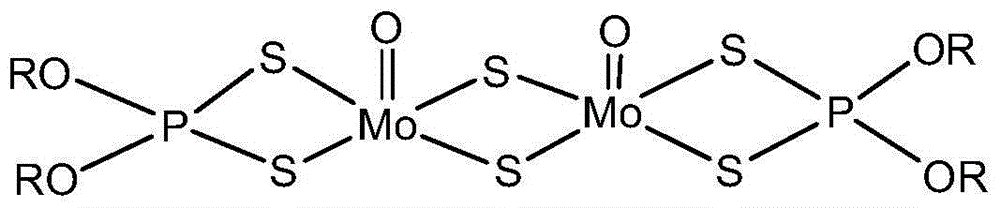

[0068] Ce(NO 3 ) 3 0.5%

[0069] Sodium molybdate 0.5%

[0070] Polyethylene wax 2%

[0071] Molybdenum disulfide 2%

[0072] Oxymolybdenum Dialkyl Dithiophosphate 2%

[0073] Nano silica 1%

[0074] Attapulgite 1%

[0075] Ethanol 10%

[0076] water 60%

[0077] The curing agent that takes by weighing 1g joins in the water-based epoxy resin of 10g, stirs 2h on the magnetic stirrer, then the Ce(NO of 0.5g 3 ) 3Add 0.5g of sodium molybdate to 10g of silane coupling agent 902, and add 1~2 drops of hydrogen peroxide, stir on a magnetic stirrer for 2-3h, mix the above-mentioned stirred water-based epoxy resin and silane coupling agent Add KH902 to 60g of water; add 2g of polyethylene wax, 2g of molybdenum disulfide and 2g of dialkyldithiooxymolybdenum to 10g of eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com