Solar photovoltaic module and manufacturing method for convergence belt leading wires of same

A technology of solar photovoltaics and production methods, applied in the field of solar photovoltaics, can solve the problems of poor lamination effect, affecting the quality of components, and air bubbles, so as to achieve good lamination effect, ensure quality, and avoid air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

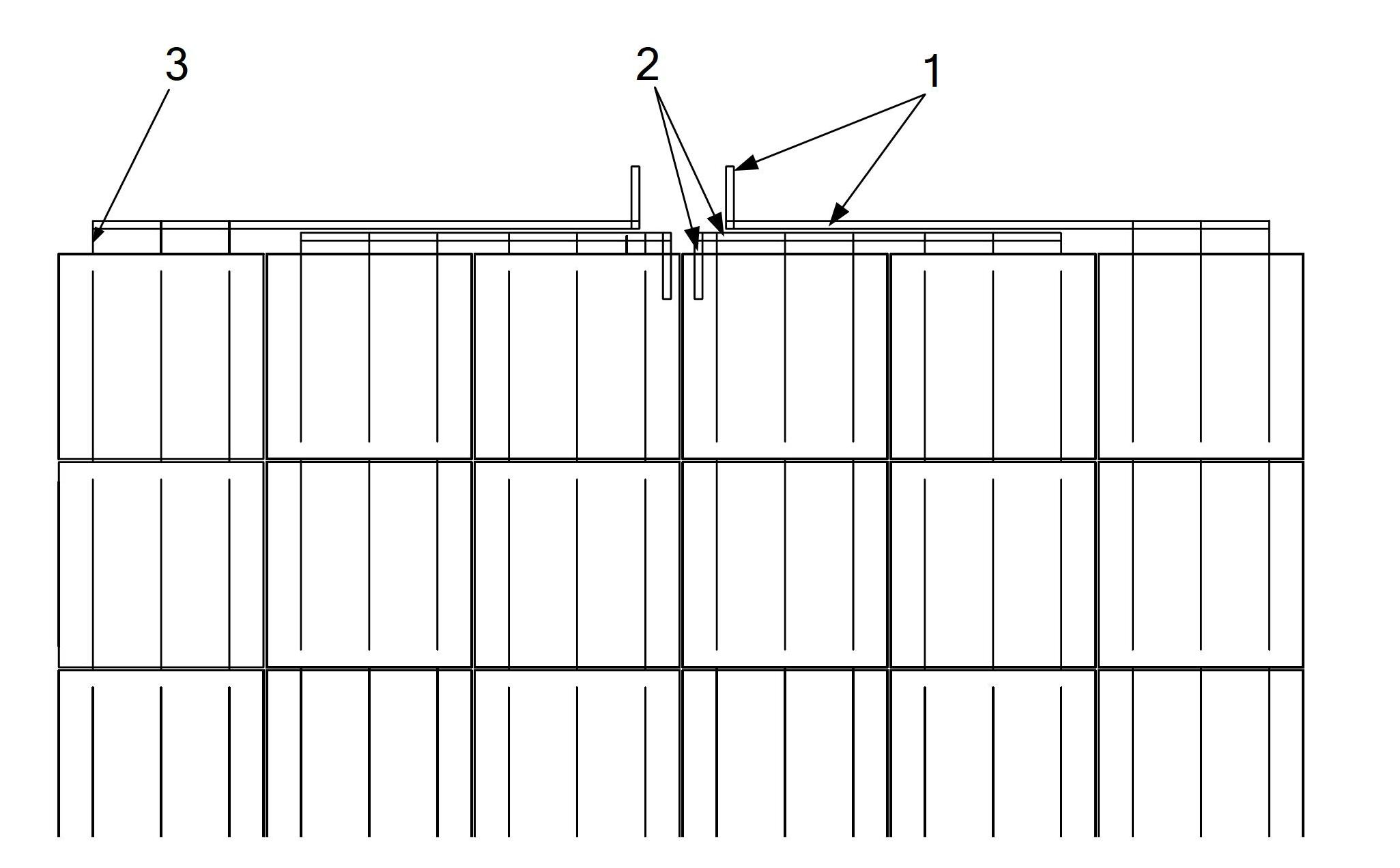

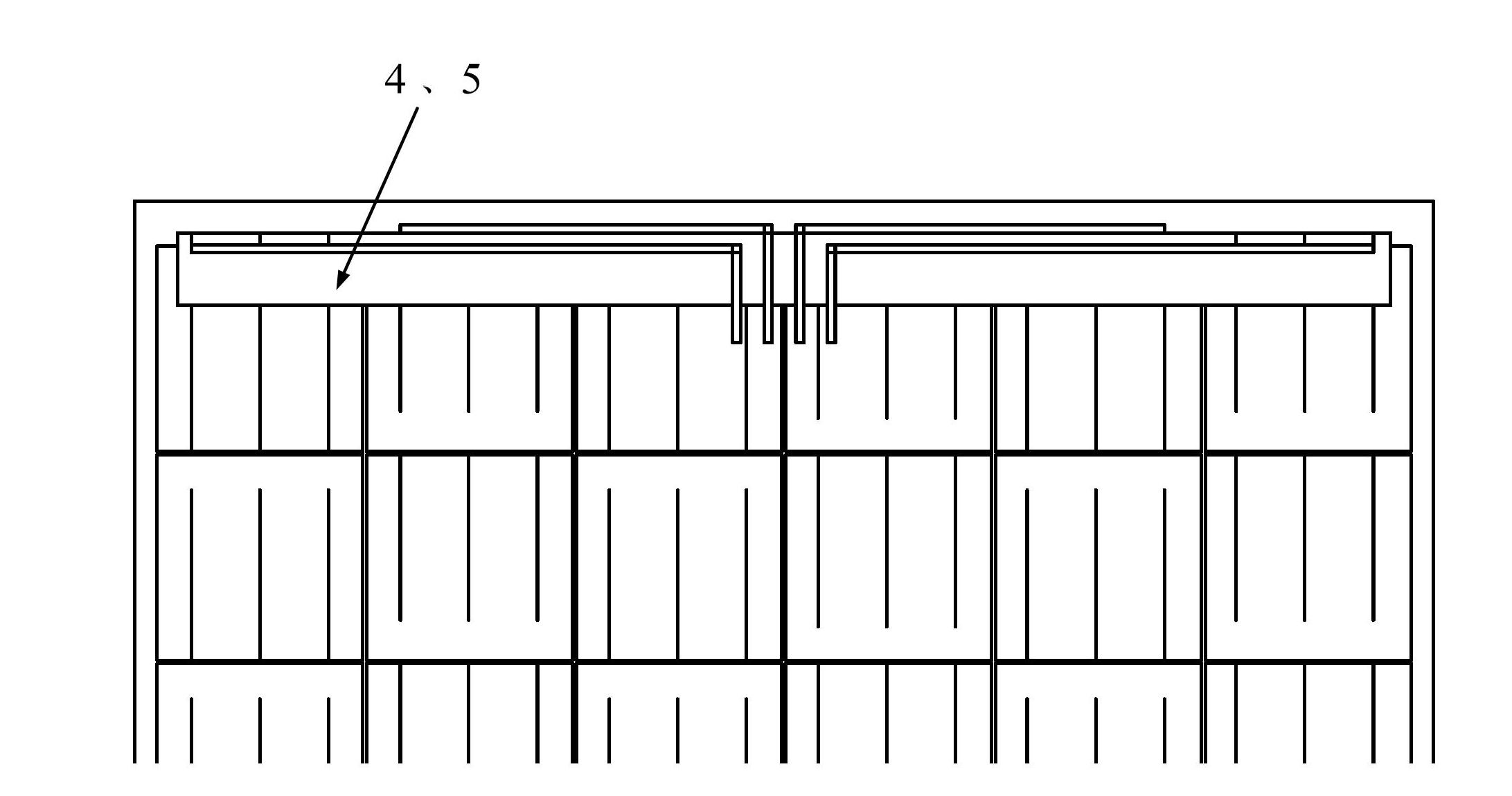

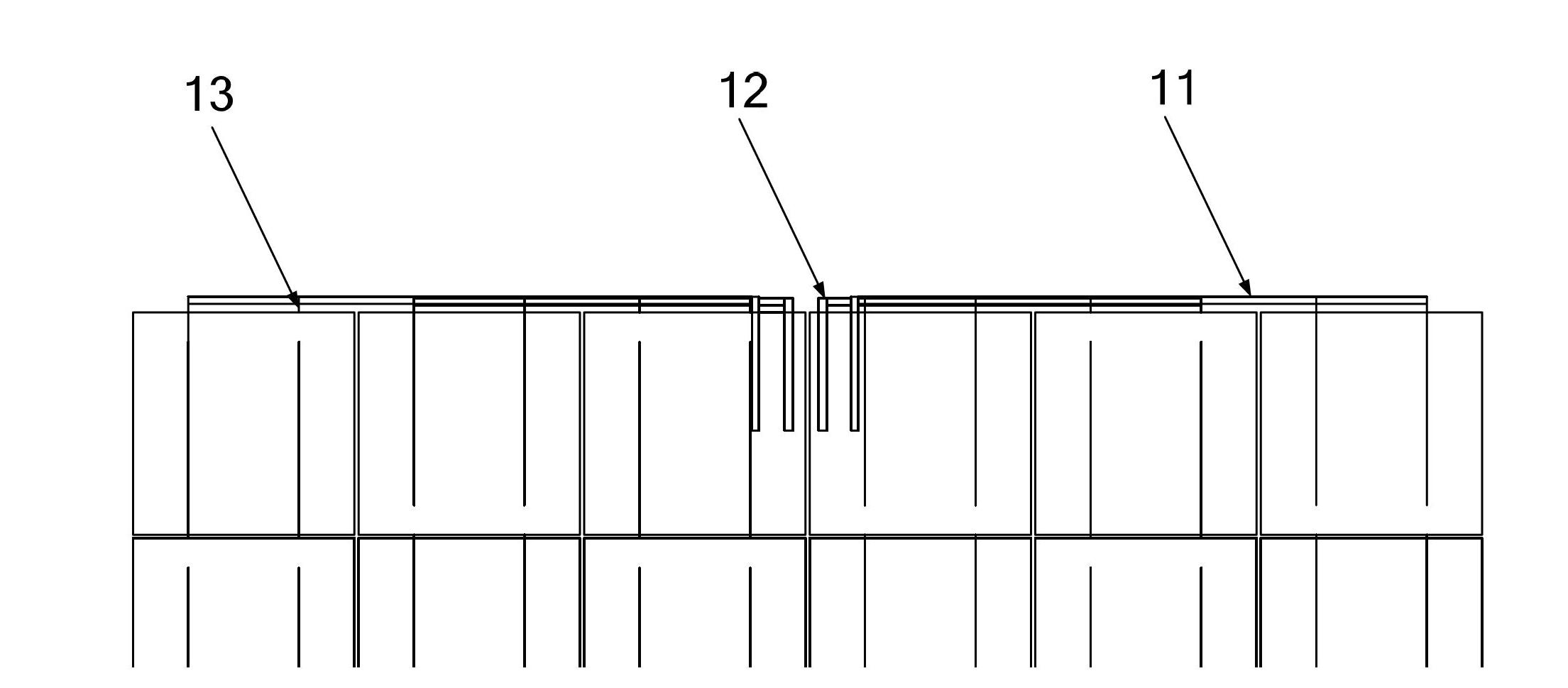

[0028] The invention discloses a method for manufacturing the lead-out wires of the confluence strips of solar photovoltaic modules, which optimizes the lead-out mode of the confluence strips and avoids the problem of cross-overlapping of the confluence strips.

[0029] For the sake of reference and clarity, the technical terms involved in this patent are now explained as follows:

[0030] Welding strip: A material used to connect cells in series and conduct current. The welding strip is composed of copper base material and welding coating.

[0031] Convergence ribbon: a photovoltaic material used to connect solder ribbons to realize the connection between packaged components and junction boxes, and play a role in dredging current.

[0032] EVA: An encapsulation material used to fix solar cells and provide a closed environment for them;

[0033] Backplane: a polymer fluorine-containing material, which plays the role of insulation for components, and also provides good environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com