Lift for outdoor substation bus operation

A technology for elevators and substations, which is applied to hoisting devices, overhead lines/cable equipment, etc., and can solve problems such as high cost, high force, and low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] Specific implementation manners: the present invention is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions.

Embodiment

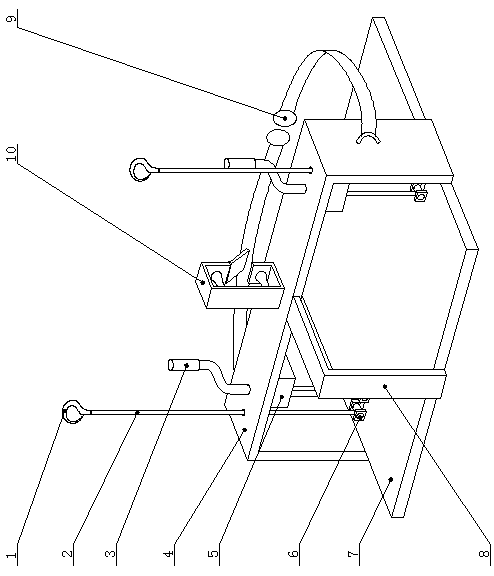

[0014] Example: such as figure 1 As shown, the substation outdoor busbar operation elevator is composed of a base 7, a steel frame 4 fixed on the base 7, a lifter 5 and a glider 10 installed on the steel frame 4. The rear part in the base 7 straddles the channel-shaped steel frame 4, and a lifter 5 is installed on both sides of the lower end surface of the steel frame 4 beams, and the crank handle 3 of the lifter 5 passes through the beam and is exposed on the upper end surface of the beam. Runner 6 is set on base plate 7 both sides, and the steel cable 2 of lifter 5 walks around runner 6 downwards earlier, turns to 180 ° again and is passed by steel frame 4 crossbeams, and the uppermost end links to each other with hook 1. The glider 10 is set in the middle of the beam. The operator sits on the base 7. For ensuring the safety of the operator, a baffle plate 8 is installed at the front end of the base 7 to the middle part of the steel frame 4 beams, and a safety buckle 9 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com