Construction method of gravel grouting pile

A construction method and technology of grouting piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing weight, reducing the strength and stiffness of the soil around the pile, solidification shrinkage, etc., achieving low unit price and avoiding pile side mud skin, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

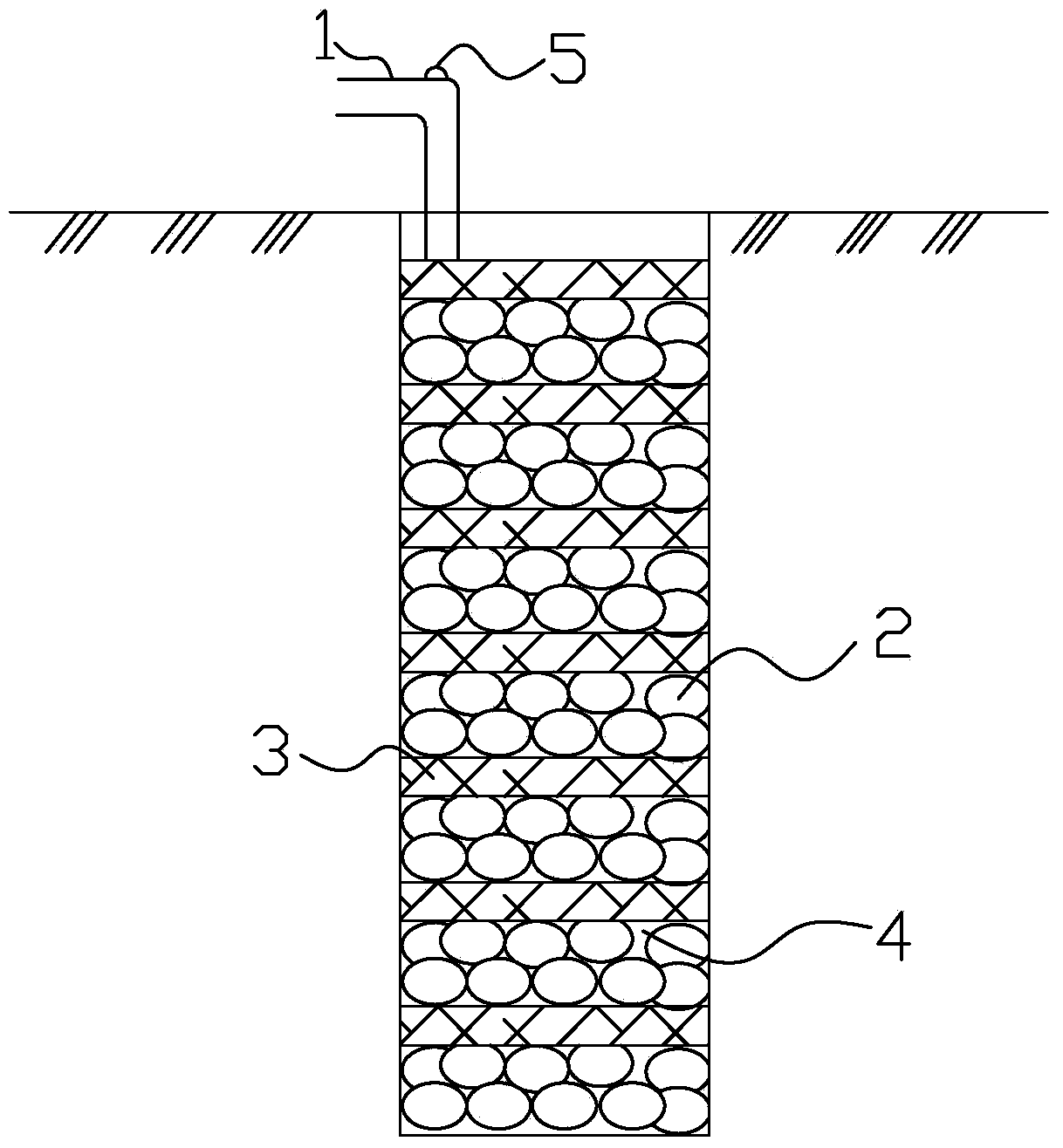

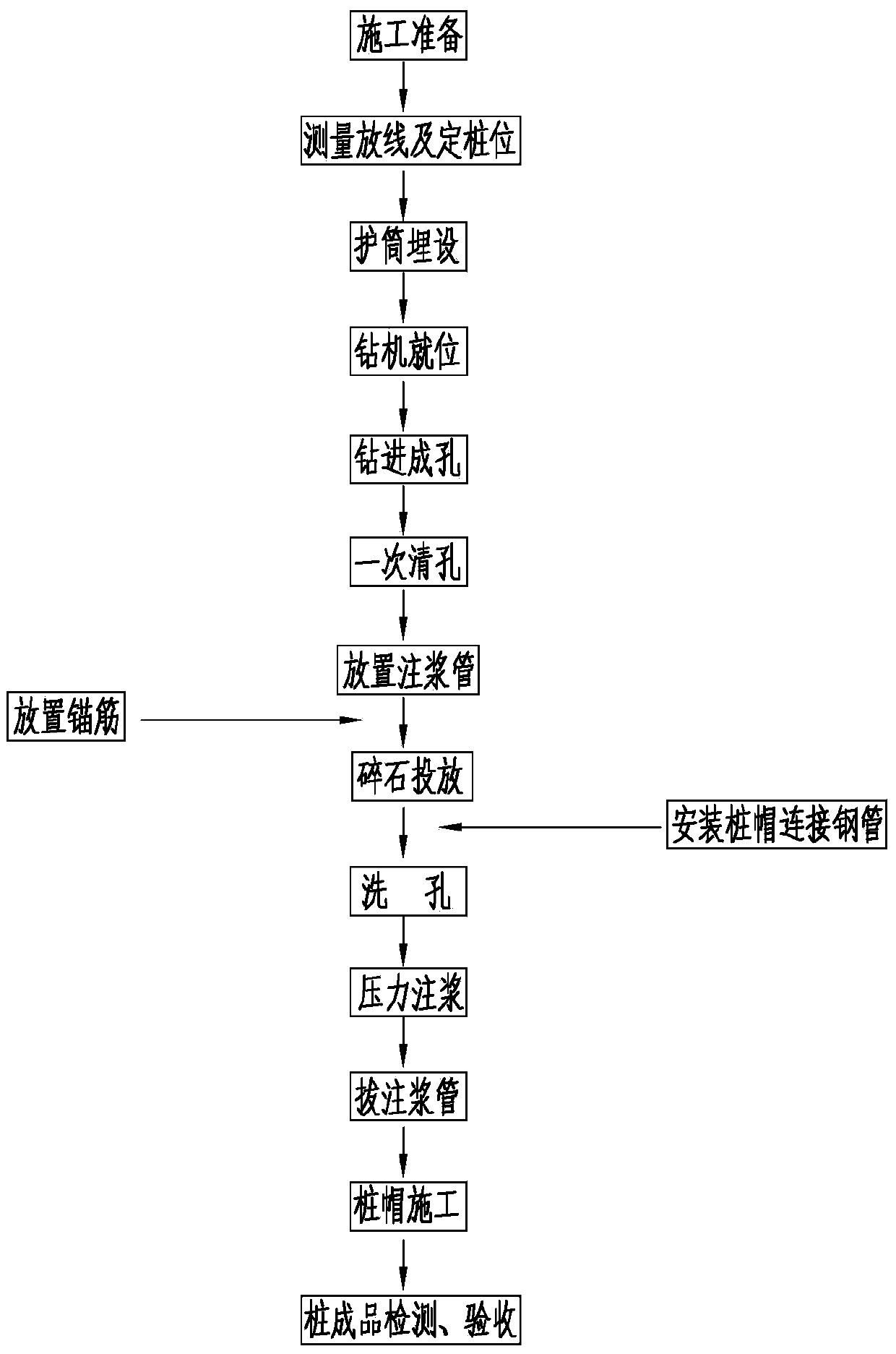

[0045] The invention discloses a construction method of crushed stone grouting piles, the working principle of which is to use an engineering drilling rig to drill a hole to a predetermined depth according to the designed pile diameter, then insert a steel grouting pipe, and then put a certain amount of crushed stone into the pile hole To the elevation, inject grout into the hole through the grouting pipe. Part of the cement slurry is combined with gravel to form a small sand-free concrete pile with a certain strength, and part of it penetrates into the soil to strengthen the soil.

[0046] This construction method requires the following materials:

[0047] 1. Total ash content: sand: water = 1:0.6:0.8, 42.5-grade ordinary Portland cement, fine sand with a fineness modulus of 2.2-2.6, gravel coarse aggregate with a particle size of 20-30mm, F Class II fly ash.

[0048] 2. Machinery and equipment: CFG-30 auger drilling rig, JDC350 mortar mixer, electric welding machine, cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com