Construction method for temporary horizontal supports serving as permanent structural beams simultaneously of deep foundation pit

A technology of horizontal support and permanent structure, which is applied in basic structure engineering, underwater structure, water conservancy engineering and other directions, can solve the problems of a large amount of construction waste, difficult to control the deformation of foundation pit, self-heavy and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by specific examples.

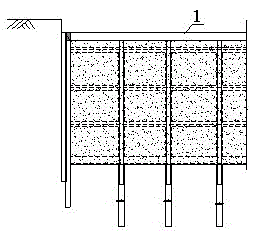

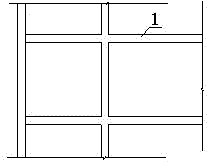

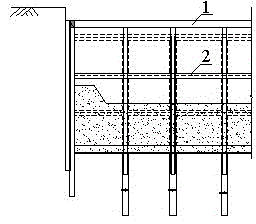

[0022] For a foundation pit project, the area of the foundation pit is more than 70,000 square meters, the average excavation depth is 17.9 meters, and there are three underground floors. The underground diaphragm wall is used as the enclosure and water-stop structure. There are three horizontal supports for the foundation pit, and the construction method of "temporary horizontal support for deep foundation pit double as permanent structural beam" is adopted. The specific steps are as follows:

[0023] The first step is to determine the position (vertical and plane), cross-sectional size, reinforcement and concrete strength of the reinforced concrete temporary horizontal support double as the permanent structural beam after design check and calculation, so that it can meet the requirements of the supporting enclosure structure and the main body of the basement at the same time. Structural force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com