Beach working hoister

A technology of cranes and jacks, which is applied in the direction of cranes, etc., can solve problems such as difficulties, unfavorable construction costs, and inability to perform construction operations, and achieve the effects of reducing loading and unloading costs, making up for insufficient one-time travel, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

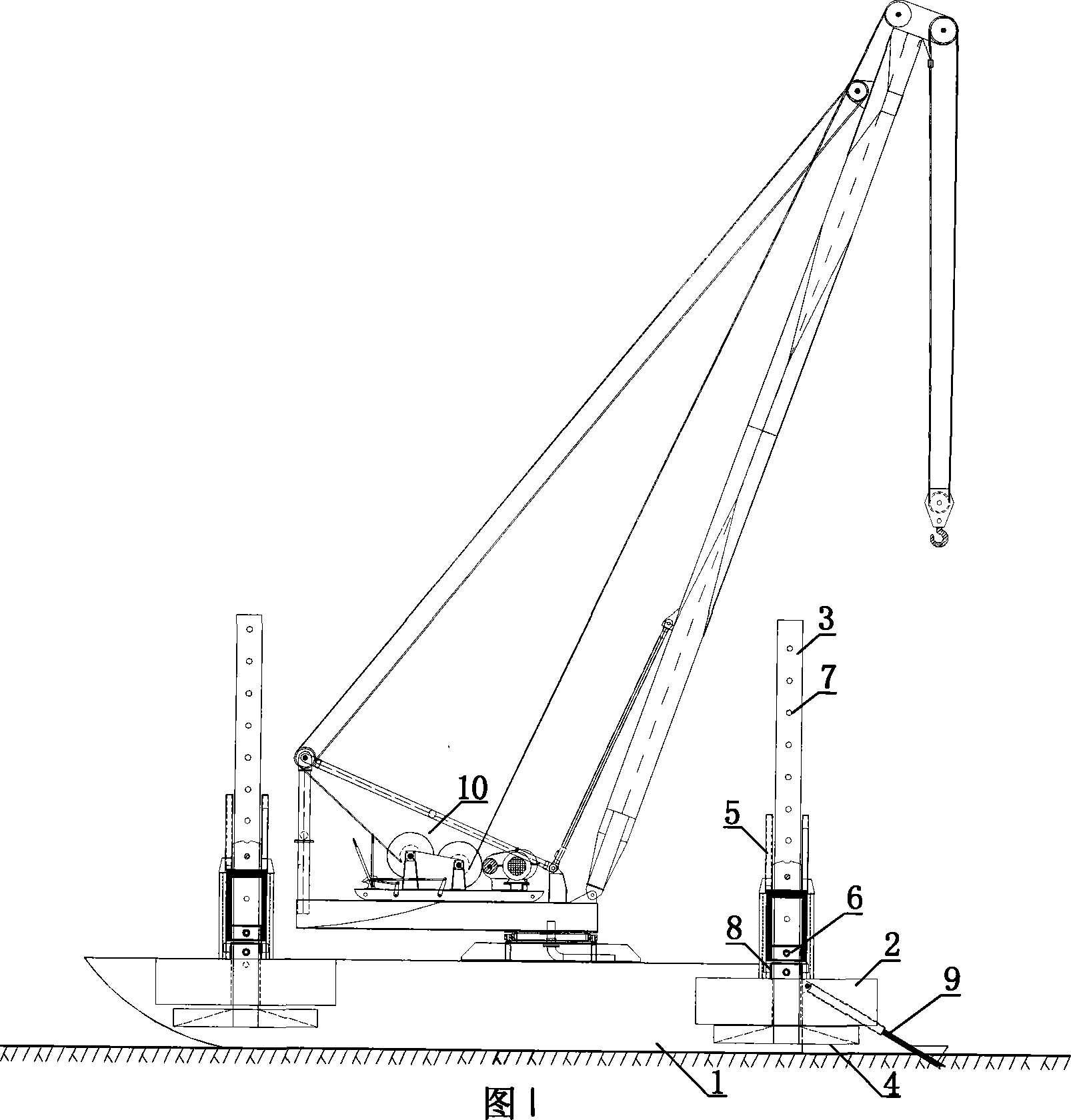

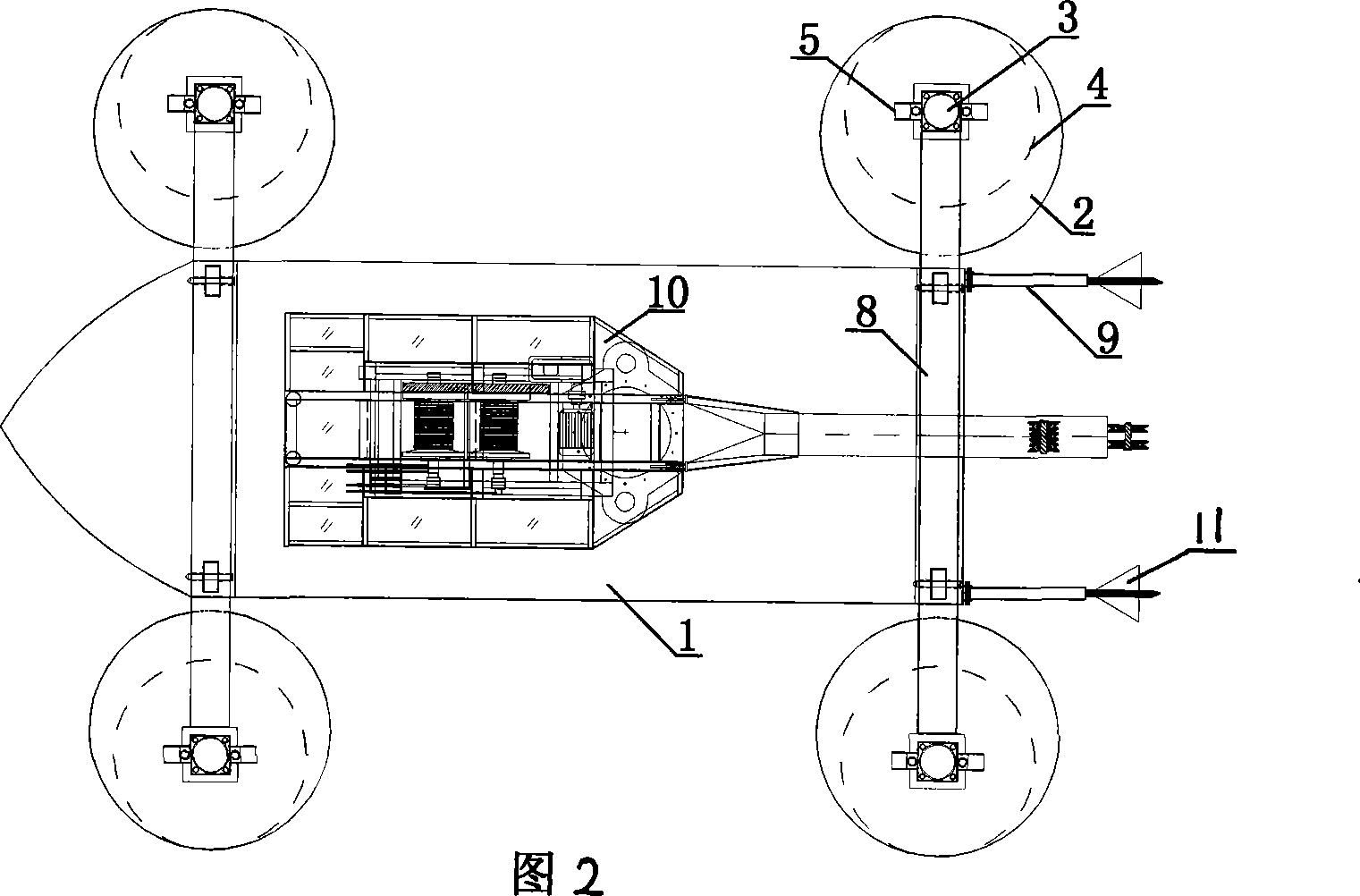

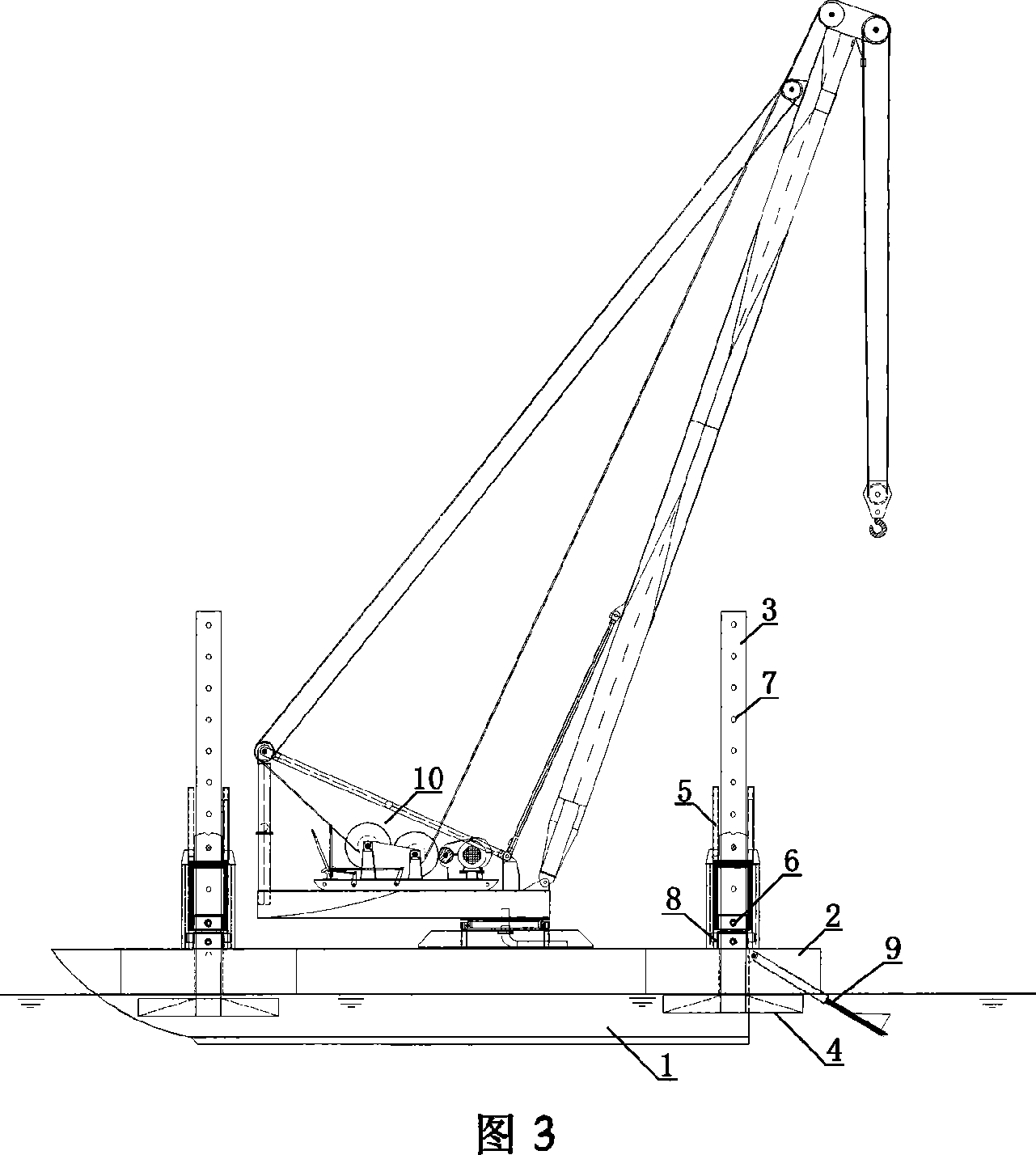

[0028] Referring to Fig. 1-Fig. 15, a crane for beach sea operation includes main buoyancy tank, stable buoyancy tank, pile legs, lifting hydraulic jack, jacking hydraulic jack and lifting crane. The combined structure of automobile transportation, its main pontoon 1 is a closed hull structure, a crane 10 is installed in the upper middle part, and a connecting beam 8 is installed in the front and rear parts respectively, and the end of the connecting beam is installed with a stable Floating box 2, pile legs 3 and lifting hydraulic jack 5 are installed on this stable floating box, and jacking hydraulic jack 9 is installed at the main pontoon rear end.

[0029] The stable buoyancy tank 2 is a circular, oval, square, rectangular or diamond-shaped structure, and a hole is arranged in the middle, and a pile leg 3, a lifting hydraulic jack 5, and an annular sleeve 6 are installed in the hole, and a bearing is installed at the lower end of the pile leg. The pressing plate 4 is evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com