Walking type pile-driving frame turning and running mechanism

A walking mechanism and walking-type technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inconvenience in construction operations, difficulty in turning and walking, and affecting construction efficiency. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

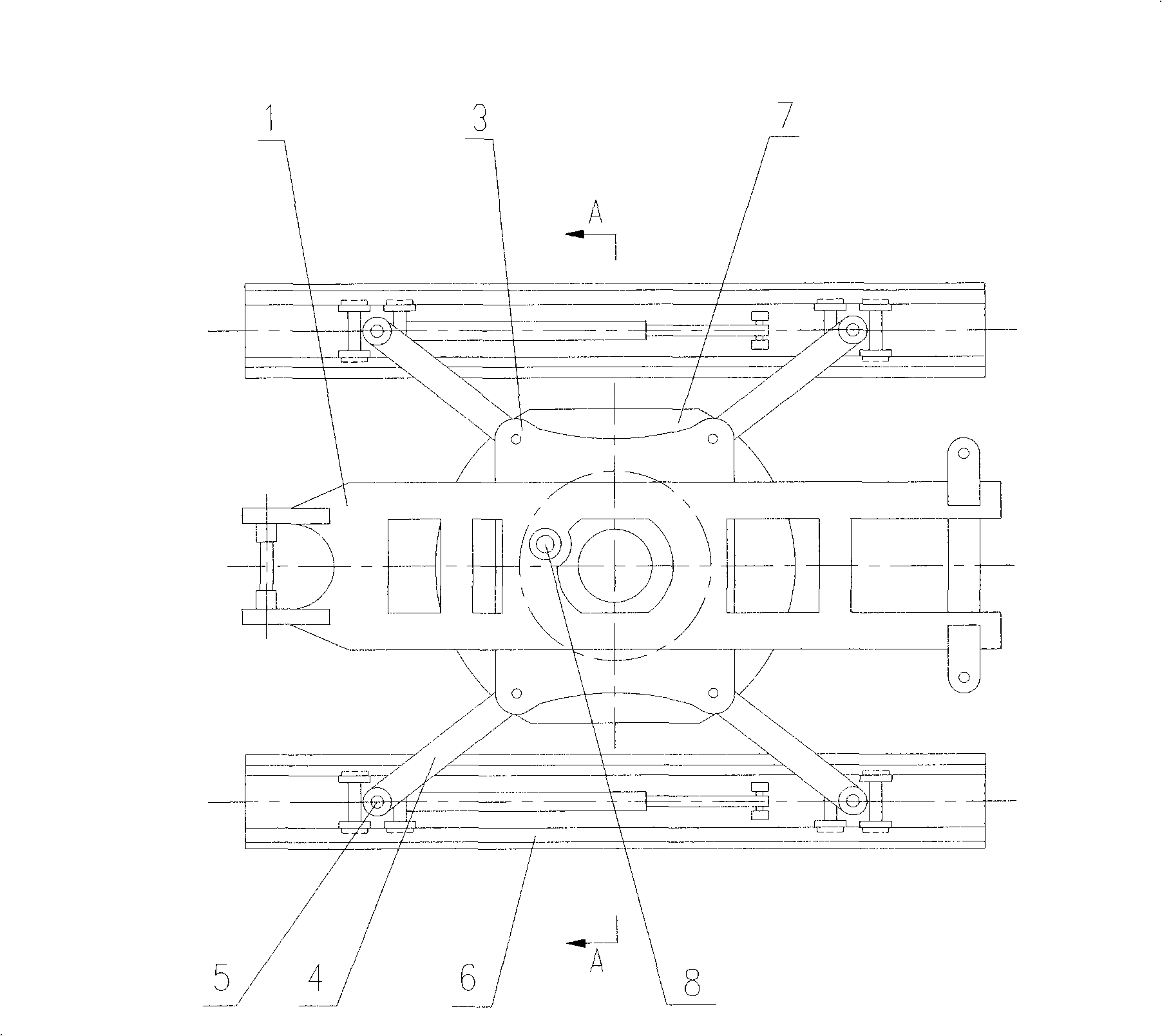

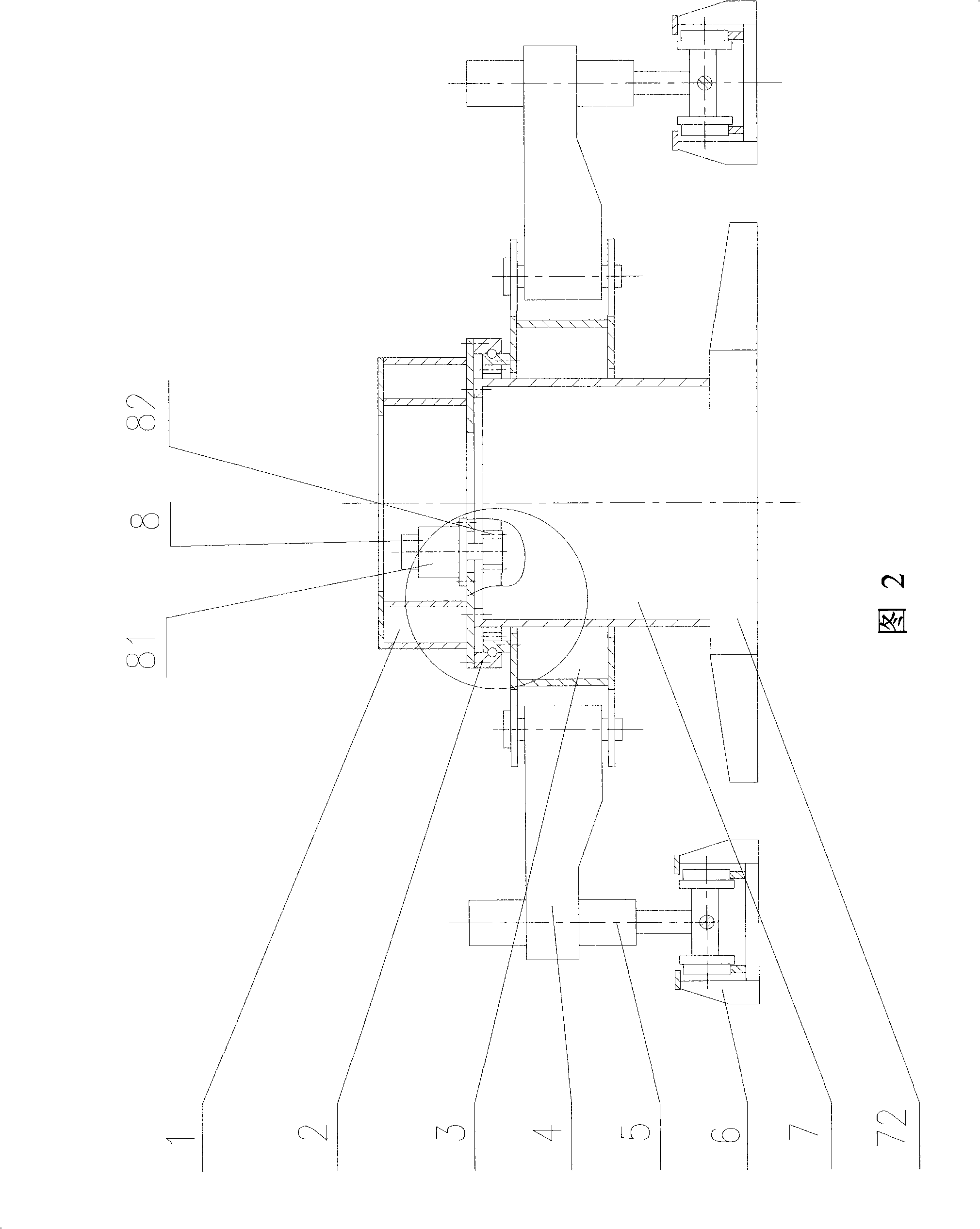

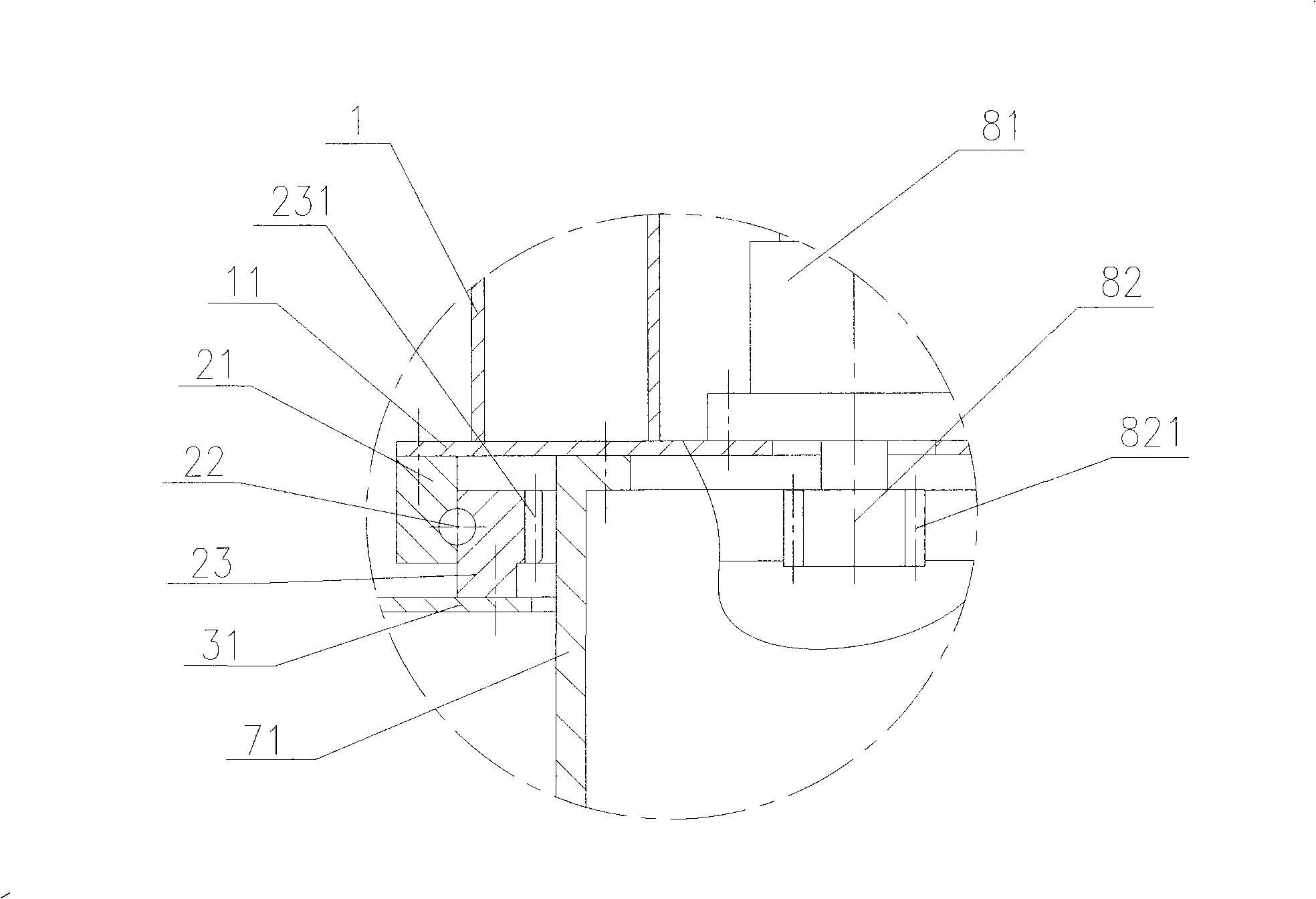

[0014] Attached below figure 1 - attached image 3 The present invention is further described:

[0015] A steering mechanism for a walking piling frame, comprising a main platform 1, a slewing bearing 2, a supporting beam 3, a supporting arm 4, an oil cylinder 5, a walking mechanism 6, and a supporting plate 7; The outer ring 21 of the slewing ring 21 and the cylinder body 71 of the support plate 7 are fixedly connected. The fixed connection method can be bolted connection, or can be connected by welding, etc., but the bolted connection is better to facilitate equipment maintenance; the inner ring of the slewing ring 2 23 and the upper cover plate 31 of the support beam 3 are fixedly connected by bolts or welding; the ball 22 is embedded in the circular groove formed by the outer ring 21 and the inner ring 23, and the outer ring 21 and the inner ring 23 are moved through the ball 22 Connection; flexible connection between the support beam 3 and the support arm 4, such as hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com