Multi-stage mixed flow primary air pipe anti-blocking system

A secondary air and mixed flow technology, which is applied in the direction of combustion air/fuel supply, combustion method, block/powder supply/distribution, etc., can solve problems such as blockage of primary air ducts and powder accumulation in primary air ducts, and achieve a solution to coal Powder clogging, simple operation, simple and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

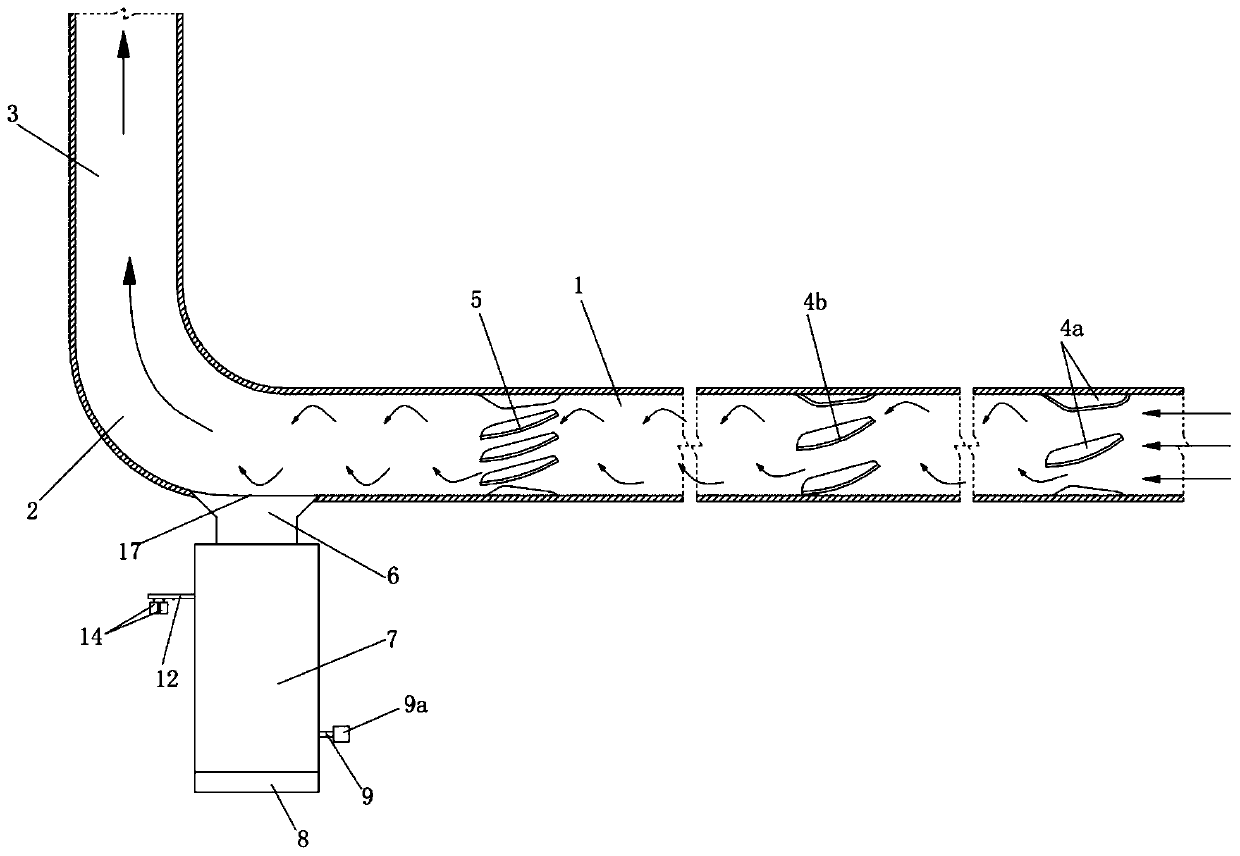

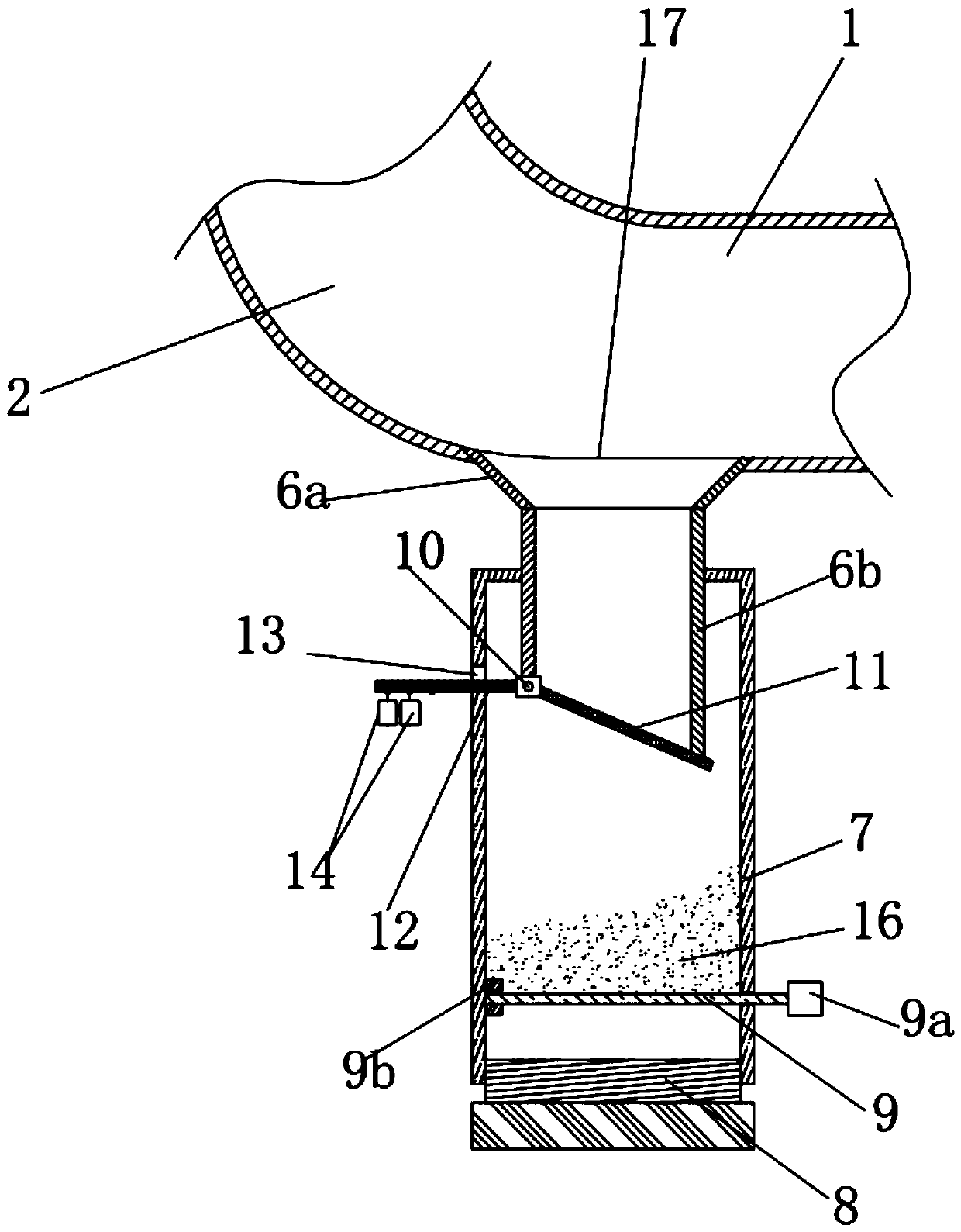

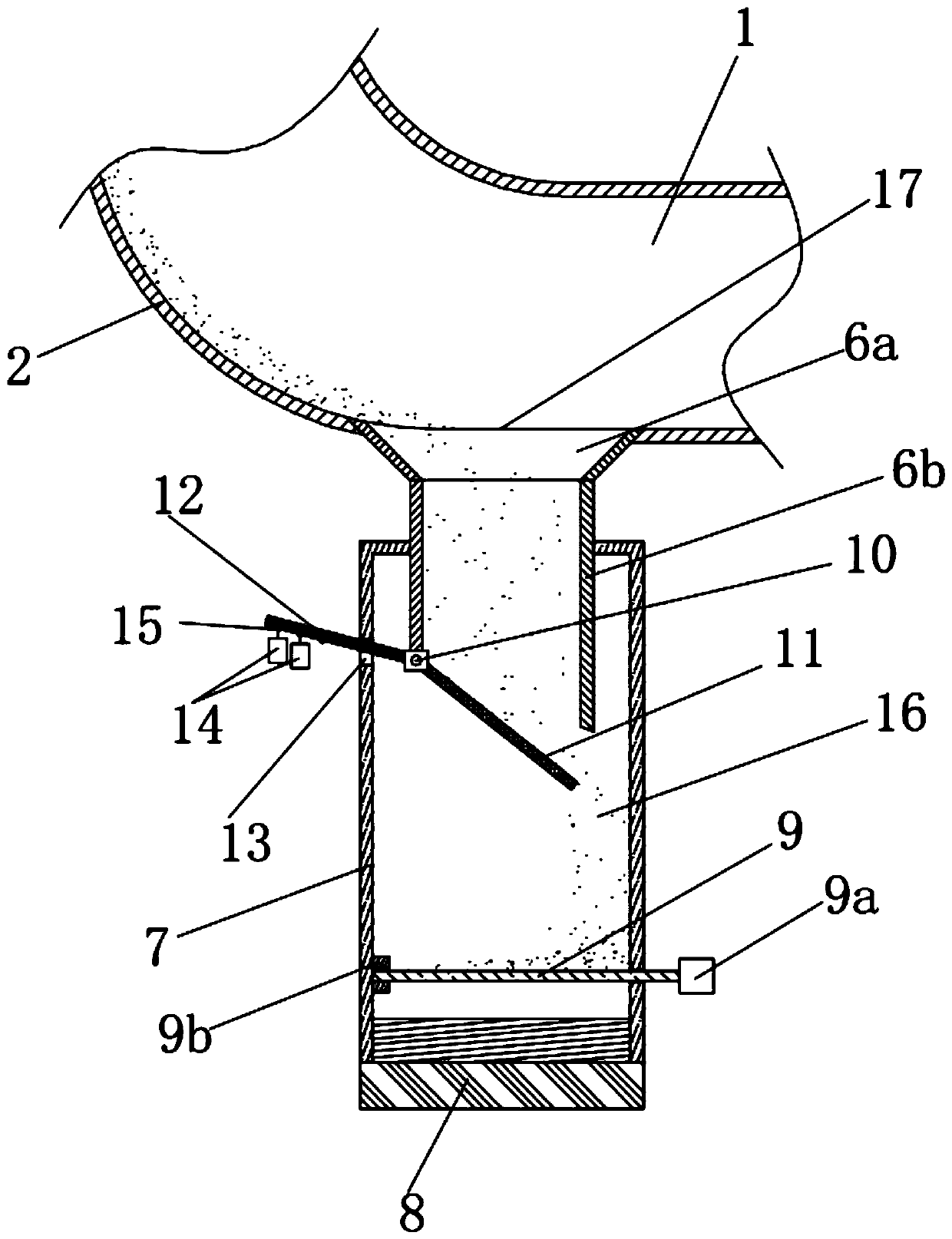

[0015] Depend on Figure 1-5 Given, the present invention includes a primary air duct, and the primary air duct is sequentially connected together by the horizontal section 1 of the primary air duct, the elbow transition section 2 and the vertical section 3 of the primary air duct to form a circular hollow tubular structure. In the horizontal section 1 of the air duct, a first-stage cyclone 4a, a second-stage mixer 4b, and a third-stage mixer 4c are arranged in sequence along the pulverized coal conveying direction. Through the powder collecting port 17, the powder collecting port 17 is connected with a coal powder collecting device extending downward, and the coal powder collecting device is connected to the dust collecting funnel 6 and the fixed dust collecting funnel connected to the lower end of the powder collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com