Air-curtain breakwater

An air curtain type breakwater and exhaust pipe technology, which is applied in the field of anti-wave lifting, can solve the problems of self-sinking, incorrect opening position, increased exhaust pipe pressure, etc., and achieves low energy consumption, excessive air outlet effect, and wave elimination effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

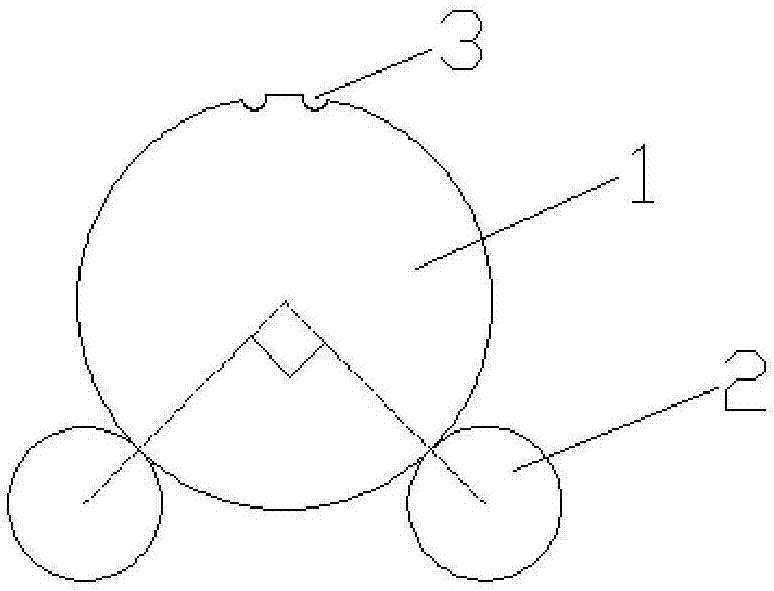

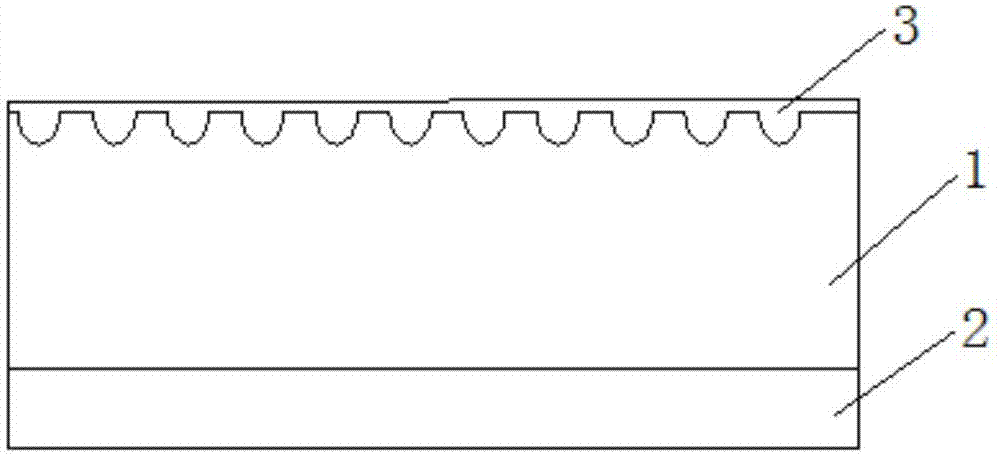

[0024] Such as figure 1 , 3 As shown, an air curtain breakwater includes an exhaust pipe 1, the exhaust pipe 1 is a cylindrical hollow pipe, and the top of the exhaust pipe 1 is provided with at least two rows of exhaust holes 3, and each row includes several exhaust holes. holes 3, the centers of all exhaust holes 3 in each row are located on the same straight line, and the straight line is parallel to the axis of the exhaust pipe 1;

[0025] Both sides of the bottom of the exhaust pipe 1 are respectively provided with a pressure water pipe 2. The pressure water pipe 2 is a cylindrical hollow pipe. Equal, the angle between the center of exhaust pipe 1 and the center of two pressure water pipes 2 is 90 degrees; The pipe diameter of exhaust pipe 1 is 100 centimeters, and the pipe diameter of pressure water pipe 2 is 20 centimeters.

[0026] In this embodiment, both the exhaust pipe 1 and the pressure water pipe 2 are made of stainless steel.

[0027] In this embodiment, the ...

Embodiment 2

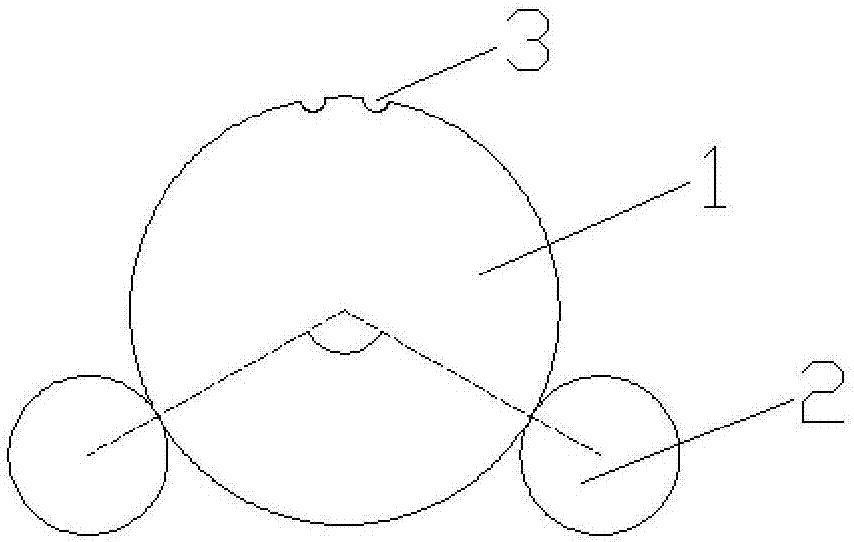

[0029] Such as figure 2 , 3 As shown, an air curtain breakwater includes an exhaust pipe 1, the exhaust pipe 1 is a cylindrical hollow pipe, and the top of the exhaust pipe 1 is provided with at least two rows of exhaust holes 3, and each row includes several exhaust holes. holes 3, the centers of all exhaust holes 3 in each row are located on the same straight line, and the straight line is parallel to the axis of the exhaust pipe 1;

[0030] Both sides of the bottom of the exhaust pipe 1 are respectively provided with a pressure water pipe 2. The pressure water pipe 2 is a cylindrical hollow pipe. Equal, the angle between the center of exhaust pipe 1 and the center of two pressure water pipes 2 is 120 degrees; The pipe diameter of exhaust pipe 1 is 100 centimeters, and the pipe diameter of pressure water pipe 2 is 33 centimeters.

[0031] In this embodiment, both the exhaust pipe 1 and the pressure water pipe 2 are made of stainless steel.

[0032] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com