Novel plastic boat

A new type of plastic technology, which is applied in the direction of hull, ship construction, and part of the hull, can solve the problems of sinking, insufficient stability and buoyancy of the ship, and dangerous use, and achieve the effect of simple structure and reducing catastrophic shipwreck accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

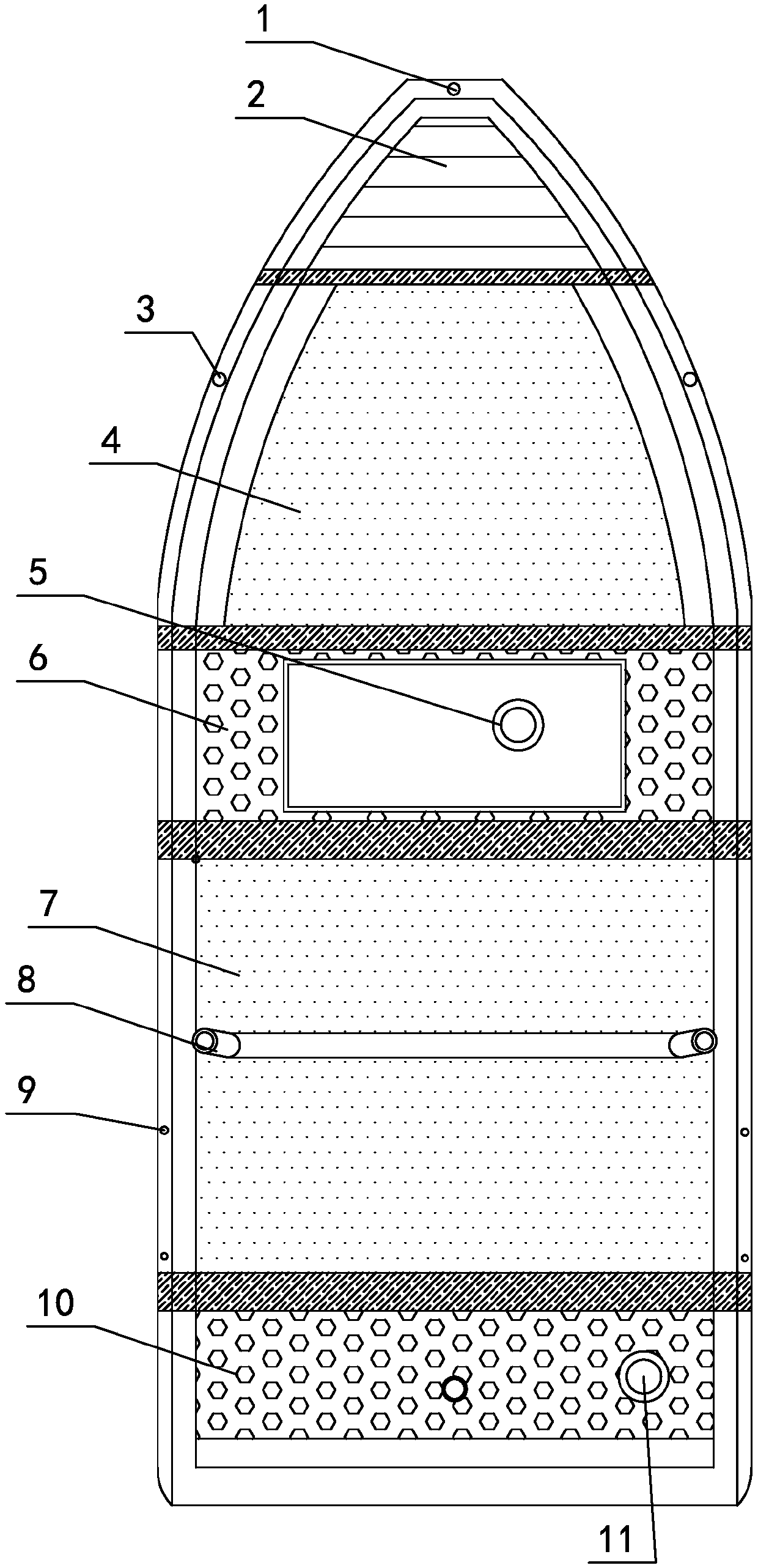

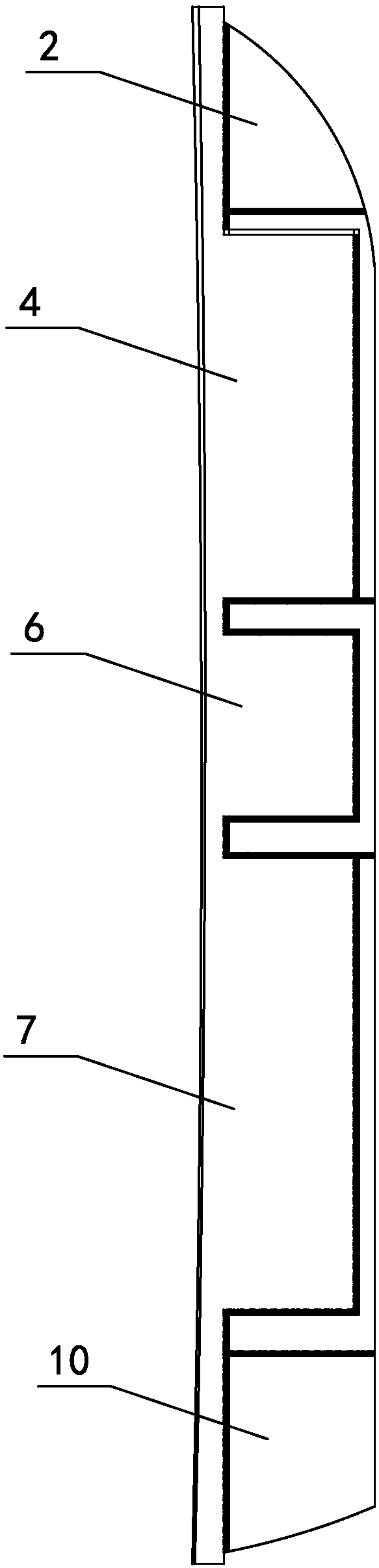

[0019] Such as figure 1 , figure 2 As shown, the new plastic boat includes a hull made of plastic, and the hull is followed by a front anti-collision cabin 2, a first cockpit 4, a living water fish cabin 6, a second cockpit 7 and a rear hanger from front to back. There are 10 and five cabins in the engine room, each cabin adopts a hollow double-layer design structure, and each cabin is an independent airtight structure, and the entire hull is made by rotational molding segmented integral molding technology.

[0020] In this embodiment, the front end of the front collision compartment 2 is provided with a traction hole 1; the traction hole 1 is used for threading cables to fix the hull.

[0021] Handrail bars 3 are arranged on the left and right sides of the first cockpit 4; it is convenient for people to board the ship.

[0022] Described living water fish cabin 6 is provided with the water inlet pipe that discharges water upwards from the bottom of the ship, and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com