A kind of phase-change microcapsule of multi-component reticular shell and preparation method thereof

A technology of phase change microcapsules and reticulated shells, which is applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of leakage of energy storage materials and high permeability of microcapsule walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

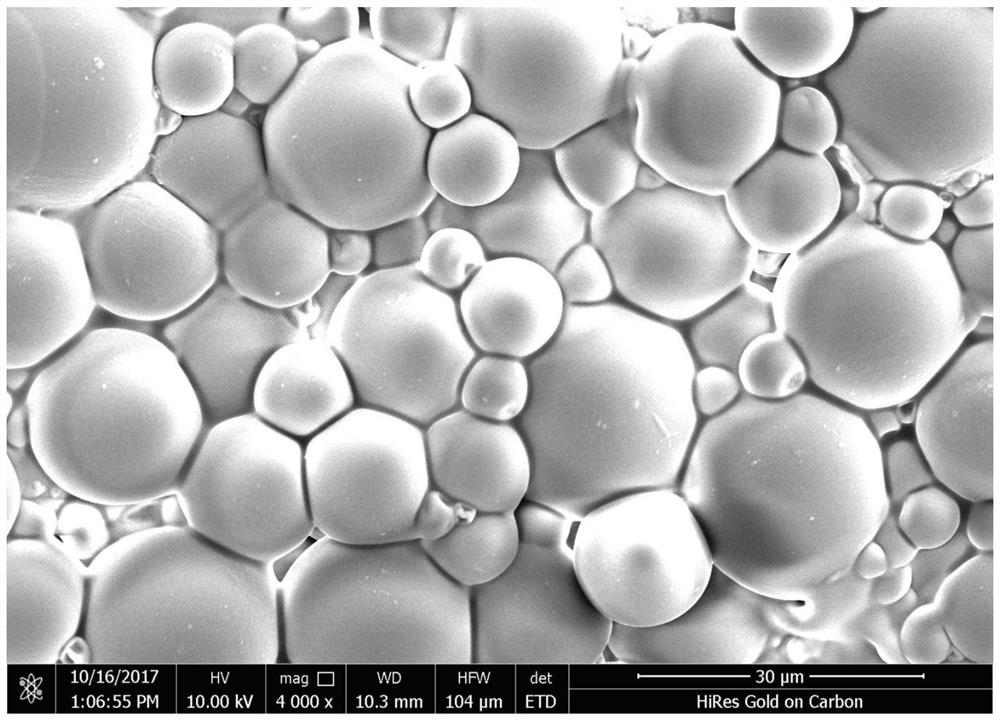

Image

Examples

Embodiment 1

[0041]This embodiment discloses a phase-change microcapsule with a multi-component reticulated shell, which includes a capsule core and a capsule wall. The capsule core component is butyl stearate, and the capsule wall is isophorone diisocyanate and two Ethylene triamine, polypropylene glycol 2000 and triethanolamine containing three hydroxyl groups react to form a polyurea polyurethane multi-component network structure resin.

[0042] The preparation method of the above-mentioned phase-change microcapsules is specifically implemented according to the following steps:

[0043] Step 1, mix butyl stearate, isophorone diisocyanate and polypropylene glycol 2000 as the oil phase medium solution of the system, wherein the mass ratio of isophorone diisocyanate to butyl stearate is 0.1:1 , The mass ratio of polypropylene glycol 2000 to isophorone diisocyanate is 0.1:1.

[0044] Step 2, take the distilled water according to the ratio that the quality of the distilled water is 4 times ...

Embodiment 2

[0052] This embodiment discloses a phase-change microcapsule with a multi-component reticulated shell, which includes a capsule core and a capsule wall. The capsule core component is octadecane, and the capsule wall is made of isophorone diisocyanate and diethylene triethylene Amine, polypropylene glycol 2000 and glycerol react to form a resin with polyurea polyurethane multicomponent network structure.

[0053] This embodiment also discloses the preparation method of the above-mentioned phase change microcapsules, specifically implemented according to the following steps:

[0054] Step 1, mix octadecane, isophorone diisocyanate and polypropylene glycol 2000 as the oil phase of the system, wherein, the mass ratio of isophorone diisocyanate to octadecane is 0.3:1, polypropylene glycol 2000 and isophorone The ratio of Fluorone diisocyanate is 0.4:1.

[0055] Step 2, weigh the distilled water according to the ratio that the quality of the distilled water is 5 times of the mass o...

Embodiment 3

[0062] This embodiment discloses a phase-change microcapsule with a multi-component reticulated shell, which includes two parts: a capsule core and a capsule wall. Amine, polypropylene glycol 1500, and trimethylolpropane react to form a resin with a polyurea polyurethane multicomponent network.

[0063] This embodiment also discloses the preparation method of the above-mentioned phase change microcapsules, specifically implemented according to the following steps:

[0064] Step 1, mix hexadecane, isophorone diisocyanate and polypropylene glycol 1500 as the oil phase of the system, wherein the mass ratio of isophorone diisocyanate to hexadecane is 0.4:1, polypropylene glycol 1500 and isophorone The ratio of Fluorone diisocyanate is 0.2:1.

[0065] Step 2 specifically is to weigh the distilled water according to the ratio of the mass of the distilled water to 6 times the mass of the hexadecane, weigh the emulsifier according to the mass ratio of the emulsifier to the hexadecane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com