Manufacturing method for reflection mirror of silicon-based LCD device

A silicon-based liquid crystal and mirror surface technology, which is applied in the photoengraving process of the pattern surface, static indicators, semiconductor/solid-state device manufacturing, etc. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

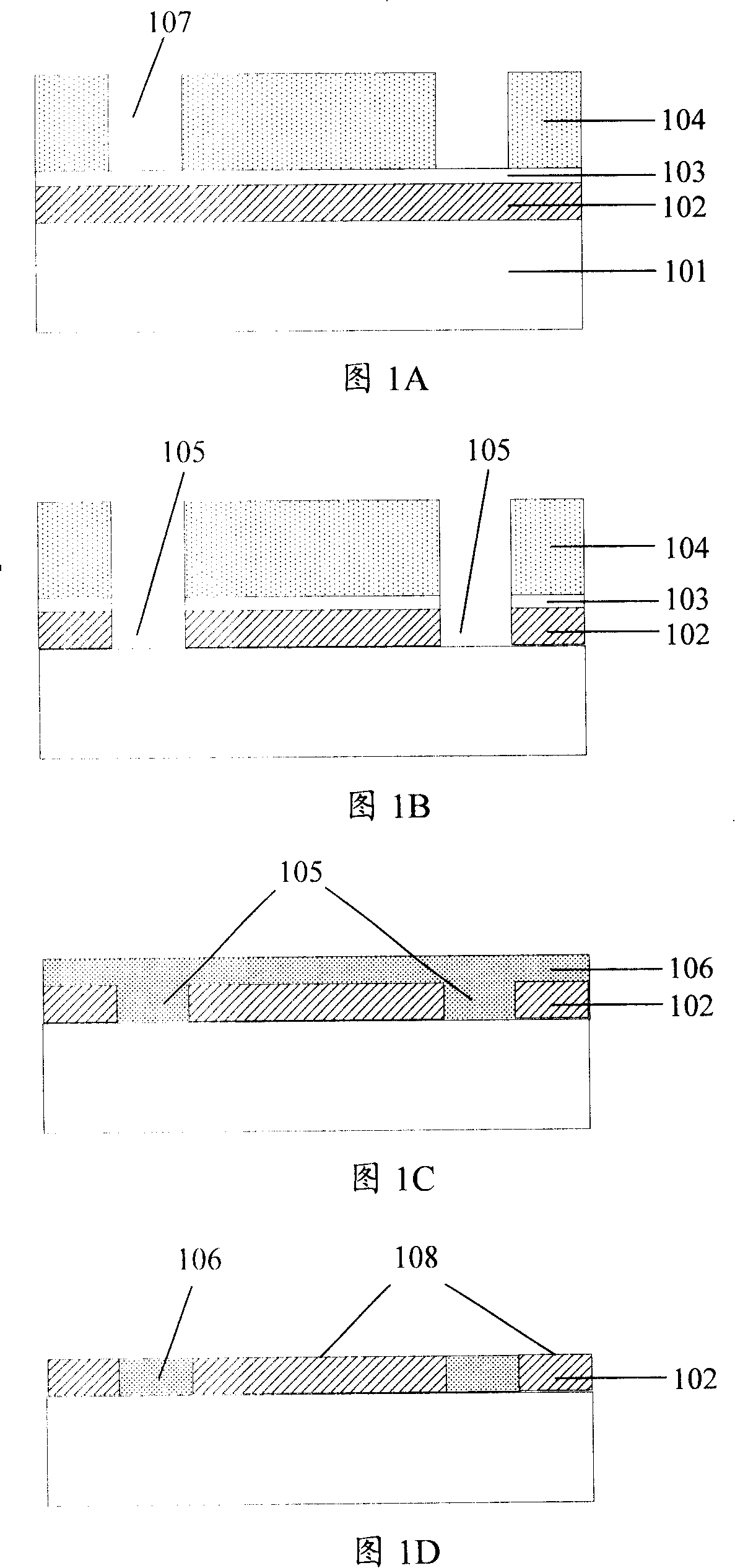

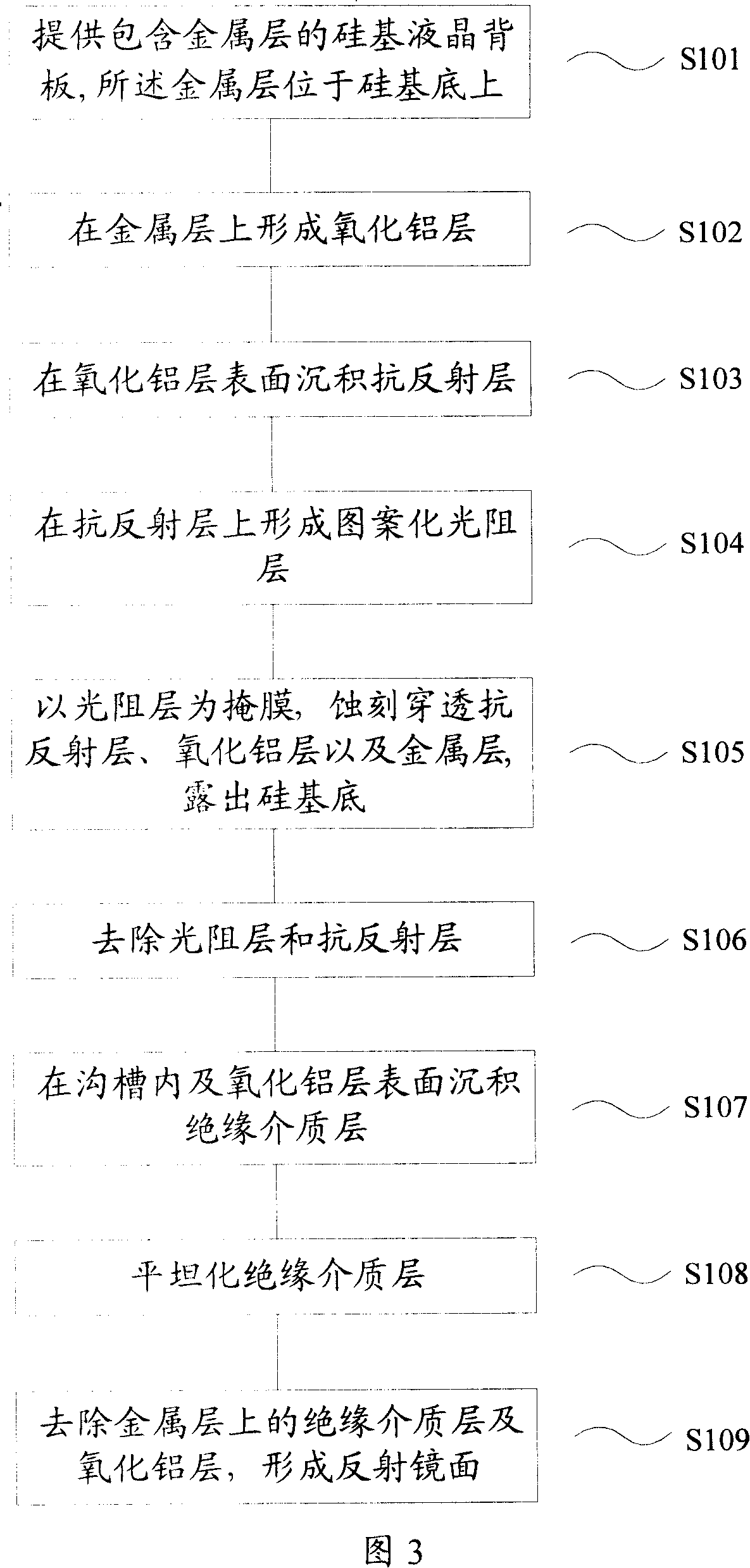

[0022] Liquid crystal on silicon (LCOS) is a new type of reflective liquid crystal display device. Unlike ordinary liquid crystals, LCOS combines CMOS technology to directly realize the driving circuit on the silicon wafer, and uses CMOS technology to make the active pixel matrix on the silicon substrate. On the bottom, it has the characteristics of small size and high resolution. In the present invention, an aluminum oxide layer is added on the surface of the metal layer, or an aluminum oxide layer and a silicon oxide layer are added simultaneously. The probability of electrochemical reaction occurring in contact with the solution is reduced, so that few depressions are produced on the reflective mirror surface, and the quality of the reflective mirror surface is improved. In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com