Waterlogged sponge energy absorption and vibration attenuation device

A technology of vibration damping device and sponge, which is applied to building components and anti-vibration, can solve the problems of large bearing burden, small vibration damping effect and limited overall damping of the structure, and achieves effective water tank space, large friction resistance and high vibration damping efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

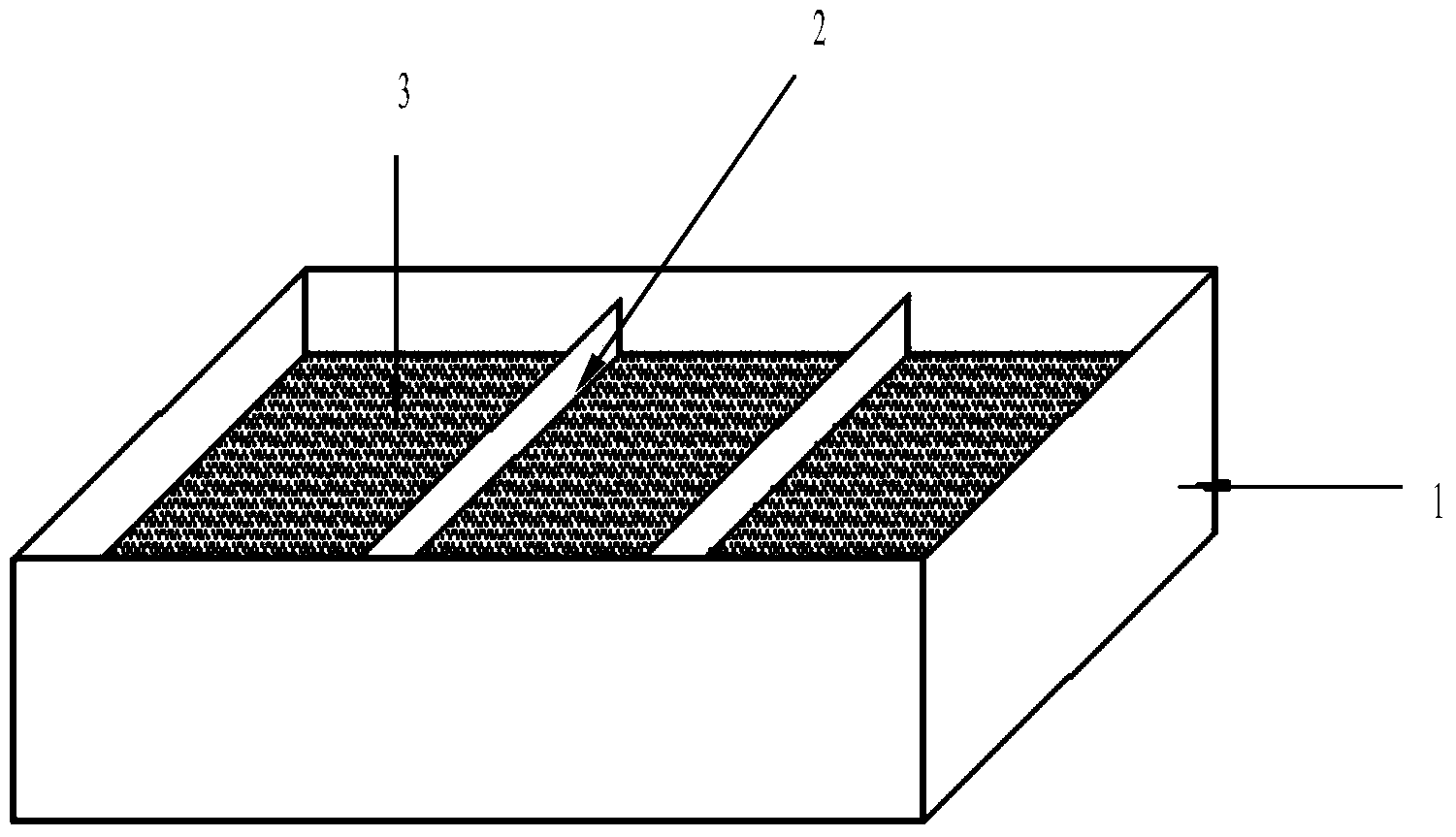

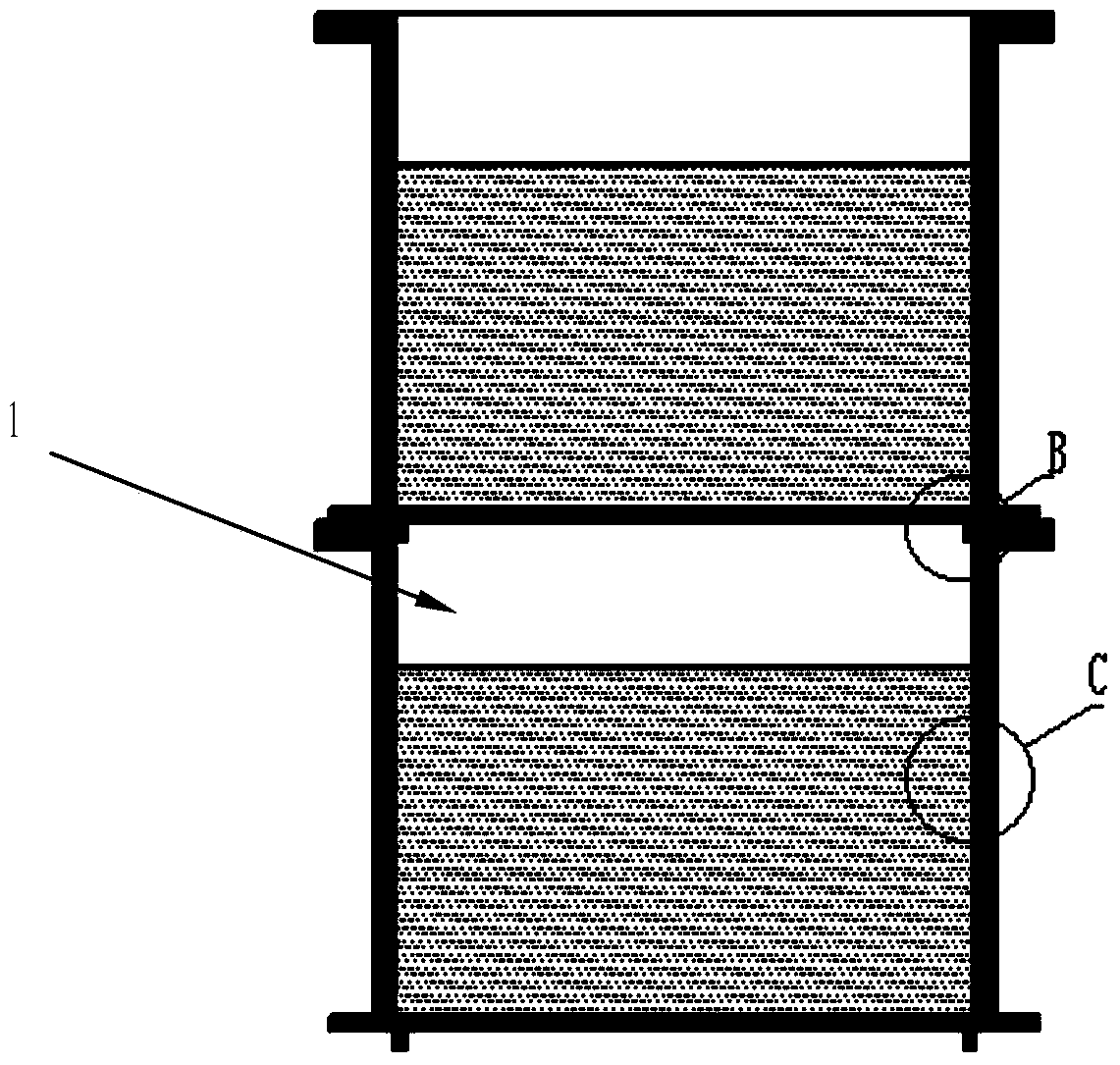

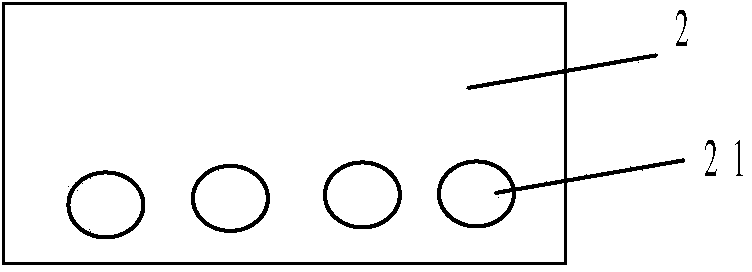

[0019] Such as figure 1 As shown, a water-saturated sponge energy-absorbing and shock-absorbing device of the present invention includes a water tank 1, a dividing plate 2 and a sponge 3. The partition board 2 divides the water tank 1 into several blocks, each block is filled with a sponge 3, and the size of the sponge 3 is slightly larger than that of the block it fills, so as to form an interference fit. Such as figure 2 As shown, there is a through hole 21 at the bottom of each partition 2 to form a connector structure so that the height of the liquid in each barrier is consistent after water injection. Due to the back and forth shaking of the liquid, the energy dissipation effect is produced. In order to make the liquid have greater resistance and better energy dissipation effect during the shaking process, each block is filled with a spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com