Improved structure of loose powder compact

The technology of a loose powder box and a powder box is applied in the directions of cosmetic powder containers, dressing containers, types of packaging items, etc., and can solve the problems of untidy powder boxes, waste of loose powder, and shaking of the powder box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

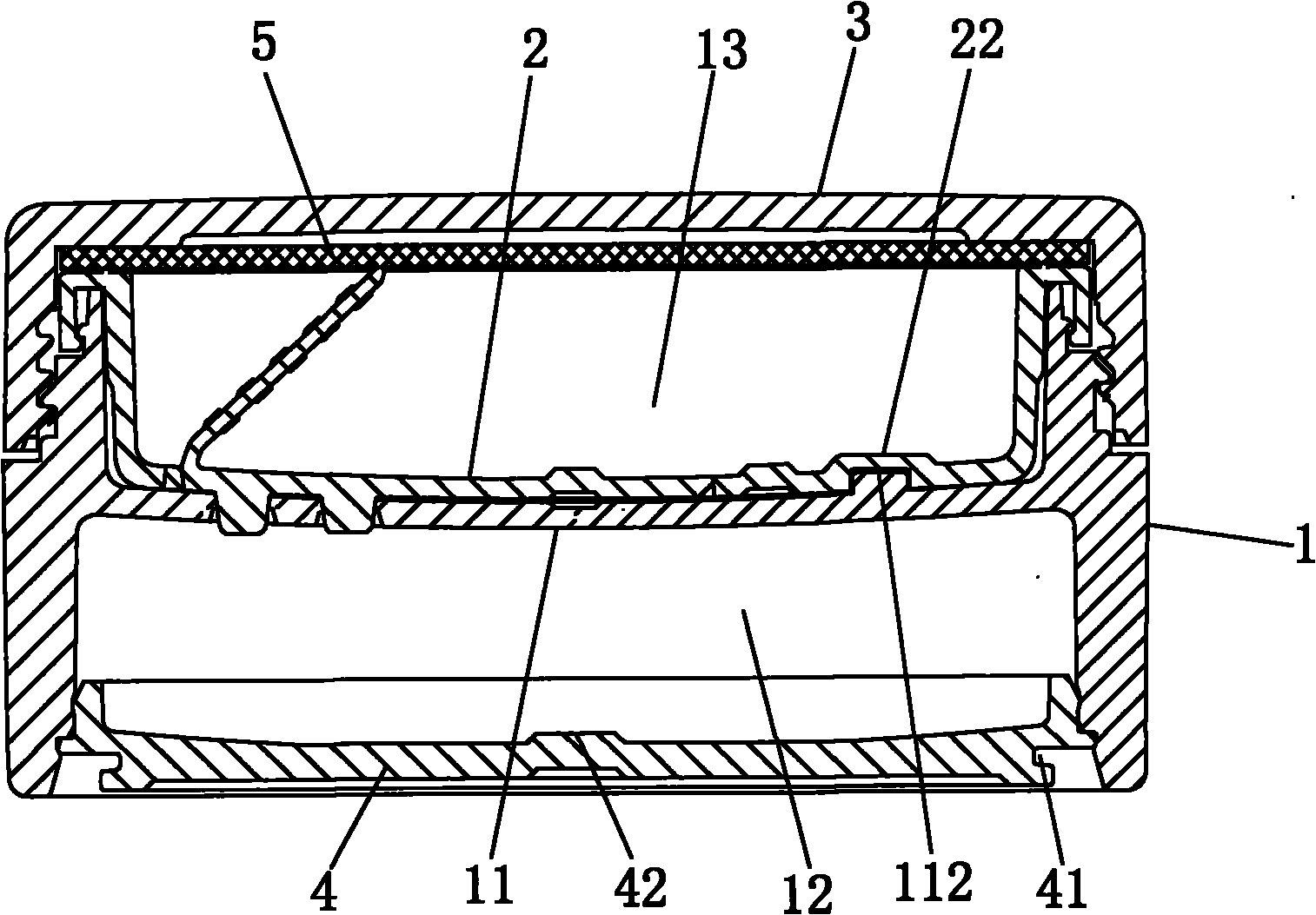

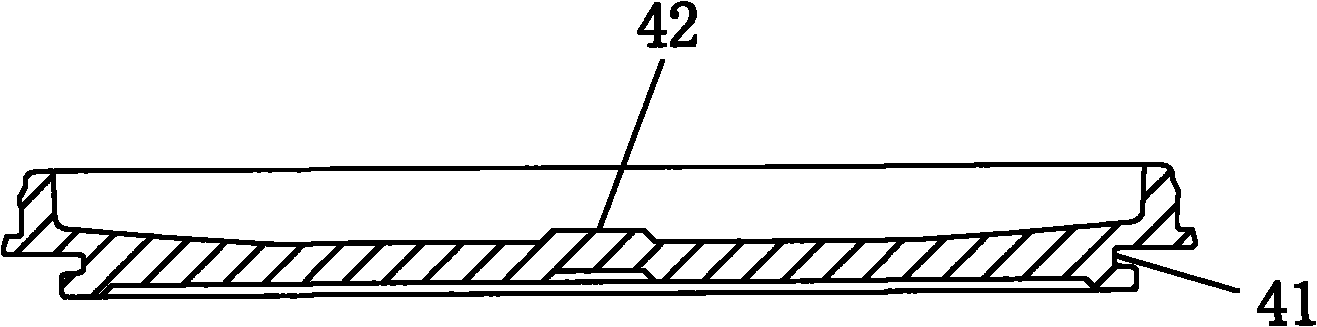

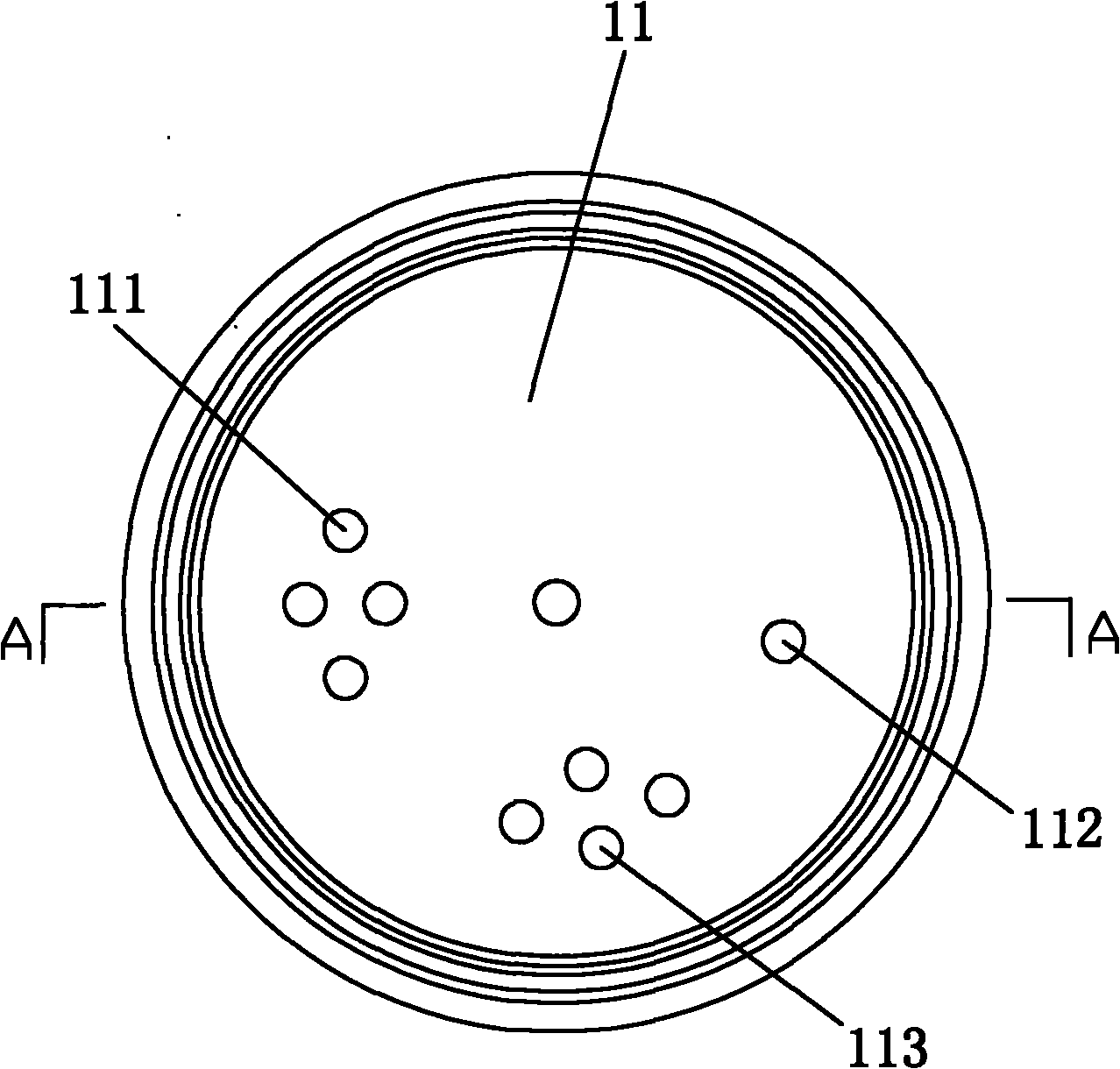

[0020] Embodiment: A structural improvement of a powder box, including a body 1, an inner sleeve 2 and a cover 3. Based on the use direction of the powder box, the body 1 is a hollow column, and a bottom plug 4 is detachably fixed at the lower end of the body. And the bottom plug can close the lower end of the body, the upper part of the body is provided with a partition 11, the partition divides the body into a loose powder accommodating cavity 12 and a loose powder access cavity 13, and the inner sleeve 2 is located in the loose powder access cavity 13, so There are several partition powder outlet holes 111 on the partition, and the inner sleeve powder outlet 21 is opened on the lower end surface of the inner sleeve. The inner sleeve can be positioned and rotated on the partition around its center, and the inner sleeve can be rotated to the inner sleeve The powder outlet hole 21 communicates with the powder outlet hole 111 of the partition, and the inner sleeve can be rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com