Discharging bag opening mechanism for horizontal packing machine

A packaging machine and blanking technology, which is applied in the field of tea packaging, can solve the problems of limited opening force, inconvenient feeding of the bag mouth, and easy falling of materials to the outside, so as to meet the requirements of use, convenient feeding and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

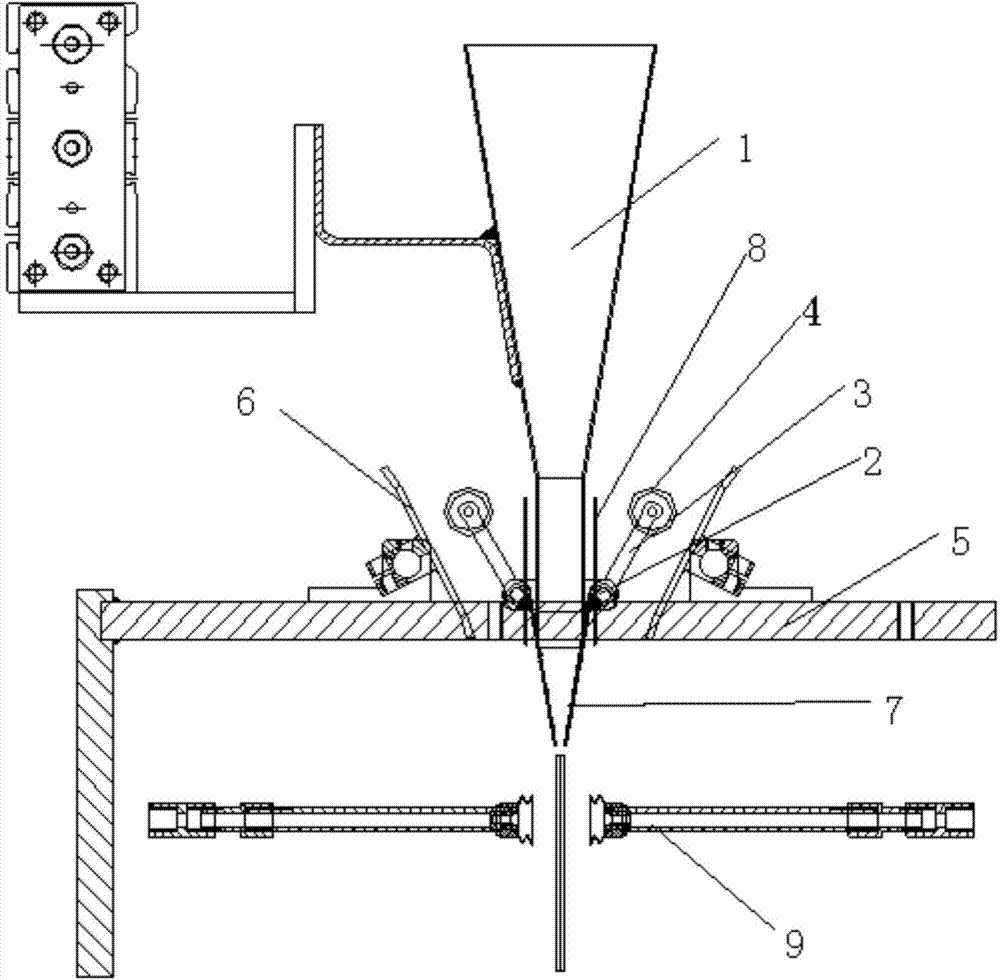

[0010] Referring to the accompanying drawings, a blanking and bag support mechanism of a horizontal packaging machine includes a lower hopper 1 that can be raised and lowered. A rotating shaft 2 is installed on both sides of the outlet of the lower hopper 1. The middle part of the rotating shaft 2 is fixedly installed with a tilting outward The opened bag support bar 3, the upper end of the bag support bar 3 is provided with a bag support roller 4, and the bag support roller 4 and the bag support roller baffle plate 6 on the fixed bracket plate 5 on both sides of the roll fit, the bag support bar 3 The upper end is provided with a bag support sheet 7, and a torsion spring 8 is installed on the rotating shaft on both sides of the bag support bar 3, and one end of the torsion spring 8 is buckled on the bag support sheet 7, and the bottom of the bag support sheet 7 is provided with an opening located at its outside. Bag suction cup 9, the movement of bag opening suction cup 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com