Garbage feeder

A feeder and garbage technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as breakage, equipment failure, and chain plate conveyor belt 8 impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

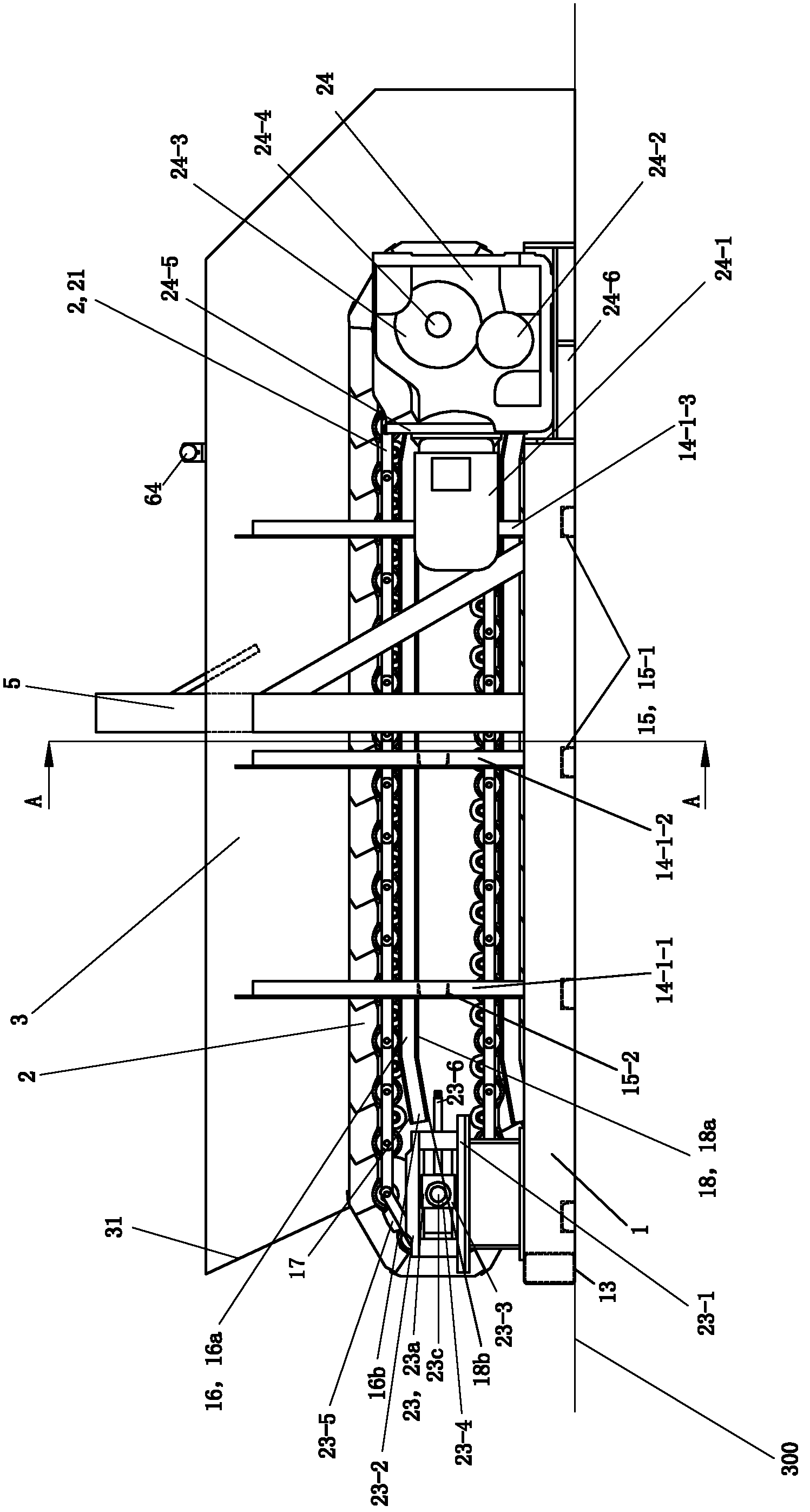

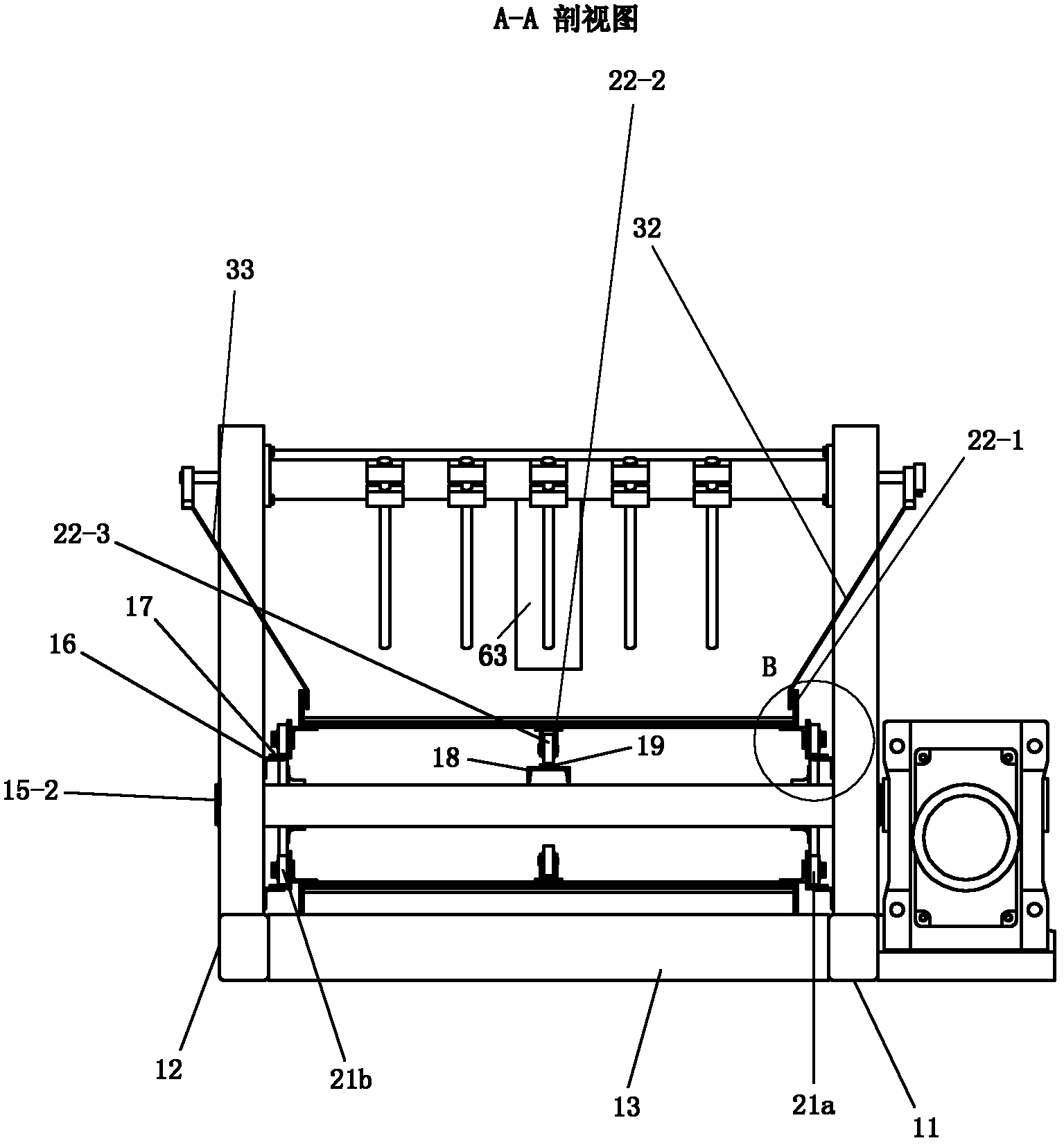

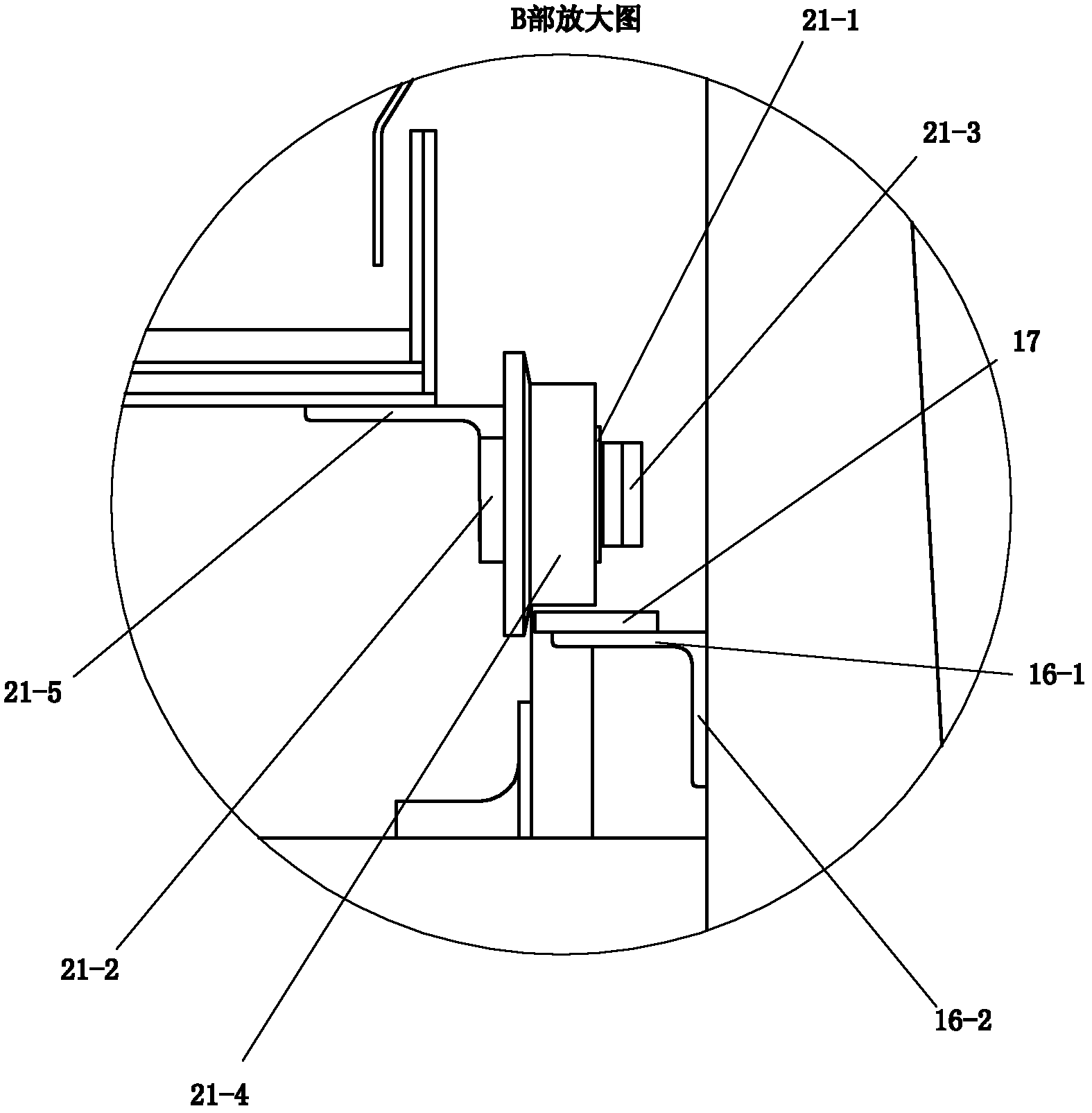

[0075] The description orientation of this embodiment is according to figure 1 The orientation shown is described, figure 1 The up, down, left, and right directions in are the described up, down, left, and right directions. figure 1 The side facing the drawing is the front side, figure 1 The side facing away from the drawing is the rear side. The two sides close to the middle part of the garbage feeder from the front-rear direction are also referred to as inner sides, and the sides farther from the middle part of the garbage feeder from the front-rear direction are called outer sides.

[0076] See figure 1 with Figure 7, The garbage feeder of this embodiment includes a frame 1, a conveying device 2, a material guide trough 3, a uniform material device 5 and a material level feedback device 6. The conveying device 2 is arranged on the frame 1 . Material guide trough 3 is fixed on the frame, and is positioned at conveying device 2 top and right. The uniform material devi...

Embodiment 2)

[0102] See Figure 9 with Figure 10 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the supporting column 14 is also provided with connecting plates 14-3, and the number of connecting plates 14-3 is the same as the number of supporting columns 14. Each connecting plate 14-3 is welded and fixed on the upper end surface of the top of the corresponding support column 14 from top to bottom; -3; the rear side plate 33 of the material guide trough 3 is welded and fixed on the connecting plate 14-3 at the top of each rear side support column 14-2.

Embodiment 3)

[0104] See Figure 13 with Figure 14 , The remainder of this embodiment is the same as that of Embodiment 1, except that the garbage feeder of this embodiment is also provided with a receiving hopper 4 and a hopper bracket 7 . The hopper support 7 is arranged on the frame 1 and is positioned at the left part of the frame 1 . The receiving hopper 4 is arranged on the hopper support 7 , located above the left part of the material guide chute 3 , and on the left side of the homogenizing device 5 .

[0105] See Figure 13 with Figure 14 , The hopper bracket 7 includes a set of diagonal braces 71 and a set of frame beams 72 . The diagonal struts 71 are divided into left diagonal struts 71a, front diagonal struts 71b and rear diagonal struts 71c according to their positions. Each diagonal strut 71 is a channel steel, and each diagonal strut 71 is arranged with an outer high and an inner low slope, and the notch faces inward. The inner side of the lower end of each diagonal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com