Freezing setting machine for shoes and boots

A technology for setting machine and footwear, which is applied to shoe uppers, footwear, insoles, etc., can solve problems such as easy diffusion temperature, delay in production speed, increase in production cost, etc., and achieve the effect of reducing the height of material volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

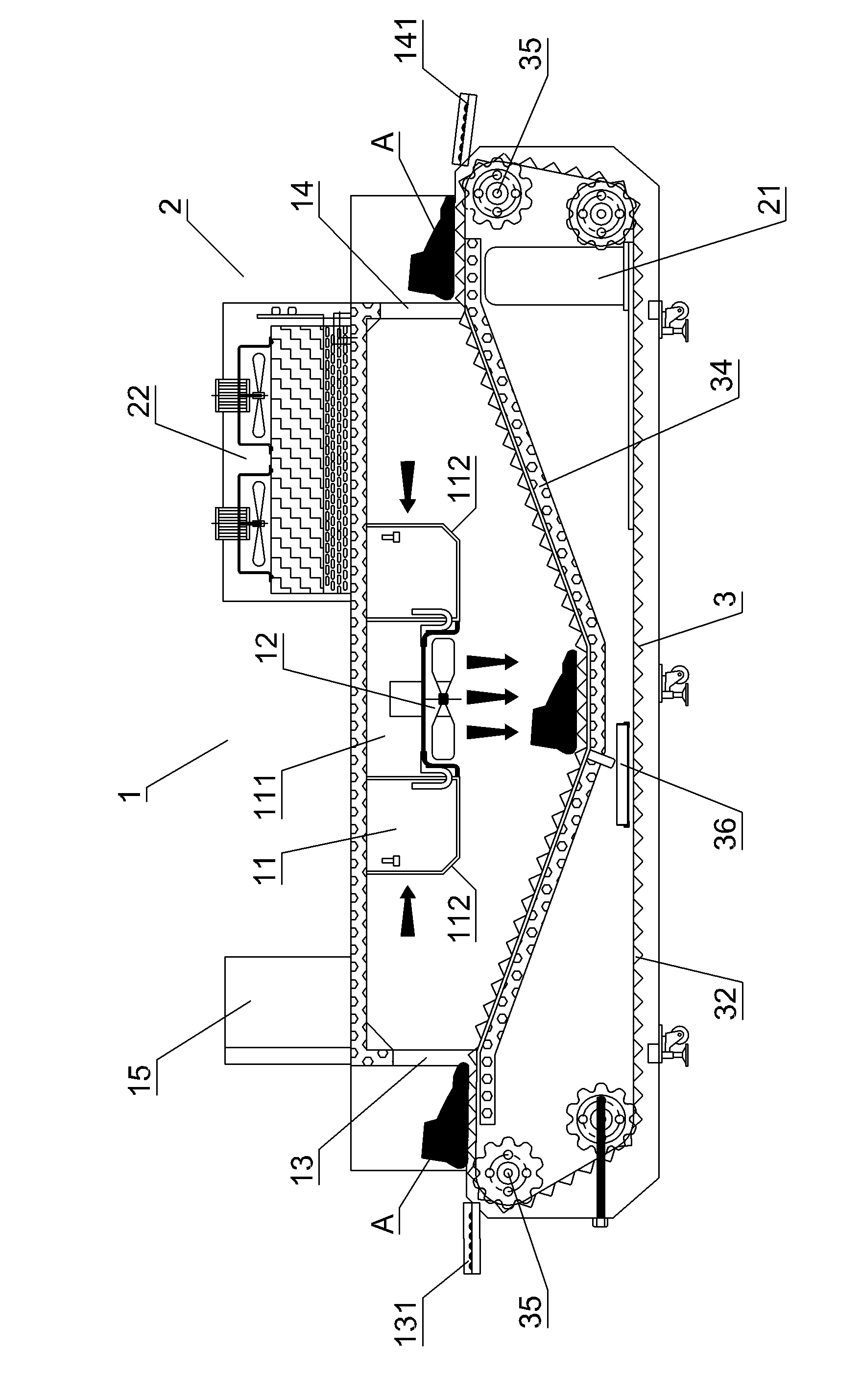

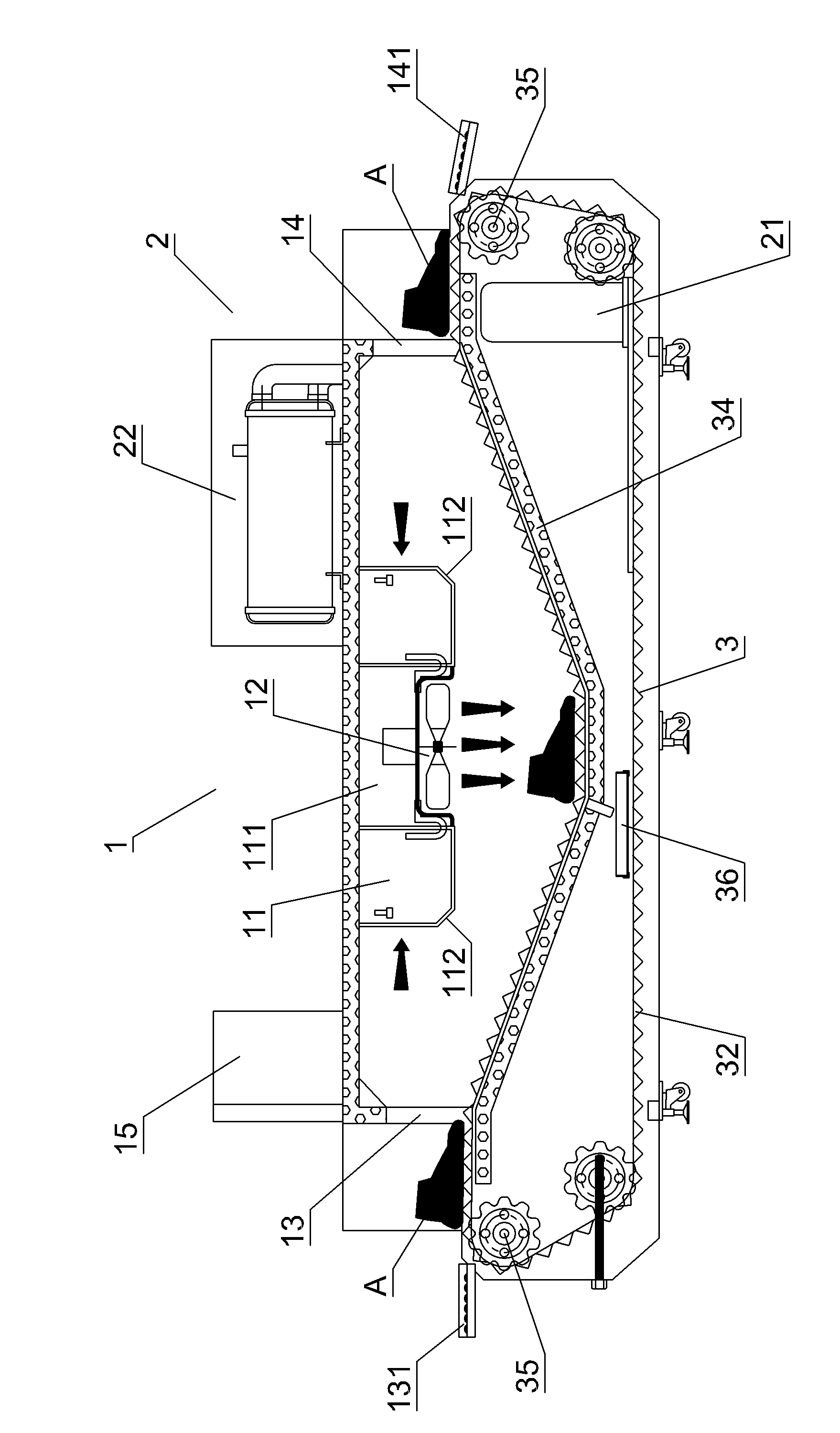

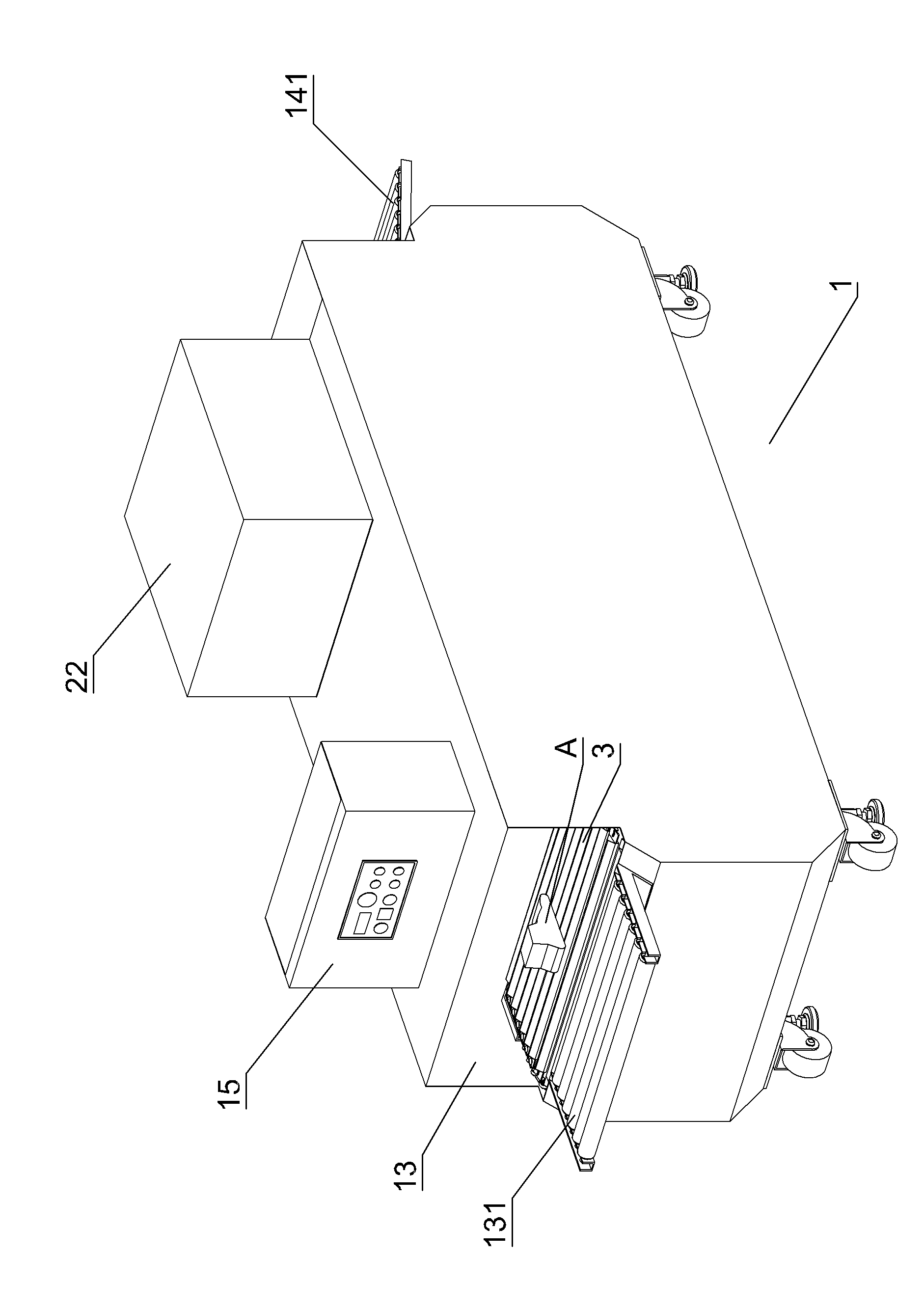

[0034] see Figure 1-2 , Figure 4-5 , Figure 5 As shown in A, a circulating space is composed of a freezing and setting machine body 1, a freezing system 2, and a concave conveying track 3; an evaporator 11 is fixed on the center of the inner surface of the top plate of the freezing and setting machine body 1, and the central upper half A gas channel 111 is preset in the upper part and at least one cooling exhaust fan 12 is provided in the lower part for lateral suction and downward blowing of circulating gas, so that the cold air generated by the refrigeration system can circulate repeatedly inside and evaporate in the An appropriate inner bevel 112 is cut at the bottom of both sides of the device 11, so as to be suitable for shoe bodies A of different heights and avoid being caught by hooks, and a material inlet 13 and a material outlet 14 are respectively provided at the openings at both ends. For sending in and out the shoe body A, and a control box 15 is installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com