Oil pressure rod device for manual power tool

A technology for power tools and hydraulic rods, which is applied to the field of hydraulic rod devices assembled and produced, can solve the problems of external gas entry, insufficient retraction force, poor wall uniformity, etc., and achieves the difficulty of convenient disassembly and simplified assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

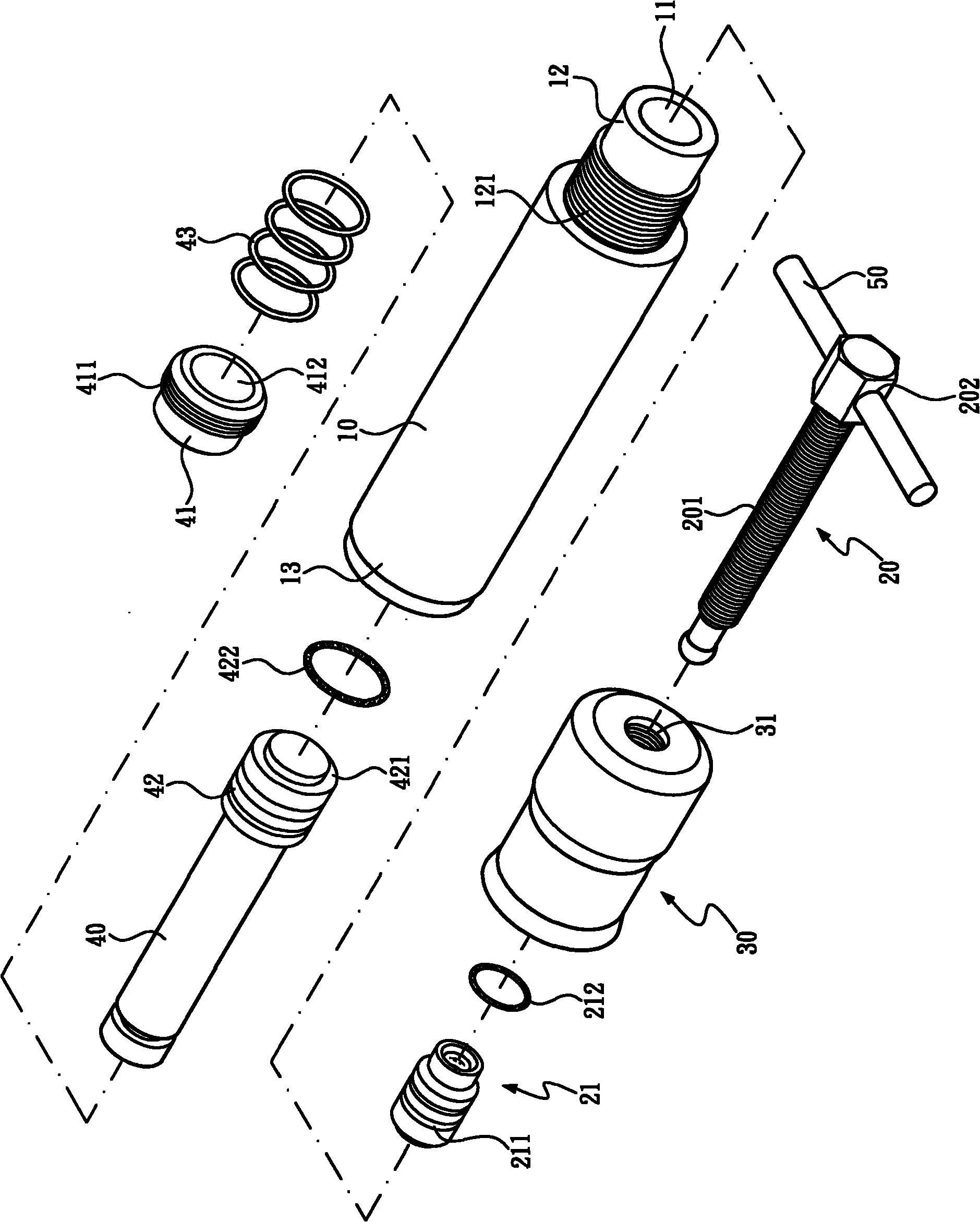

[0033] For ease of explanation this case expresses in the above-mentioned content of the invention column central thought, hereby expresses with specific embodiment. Various objects in the embodiments are drawn in proportions suitable for illustration rather than actual components, and are described first.

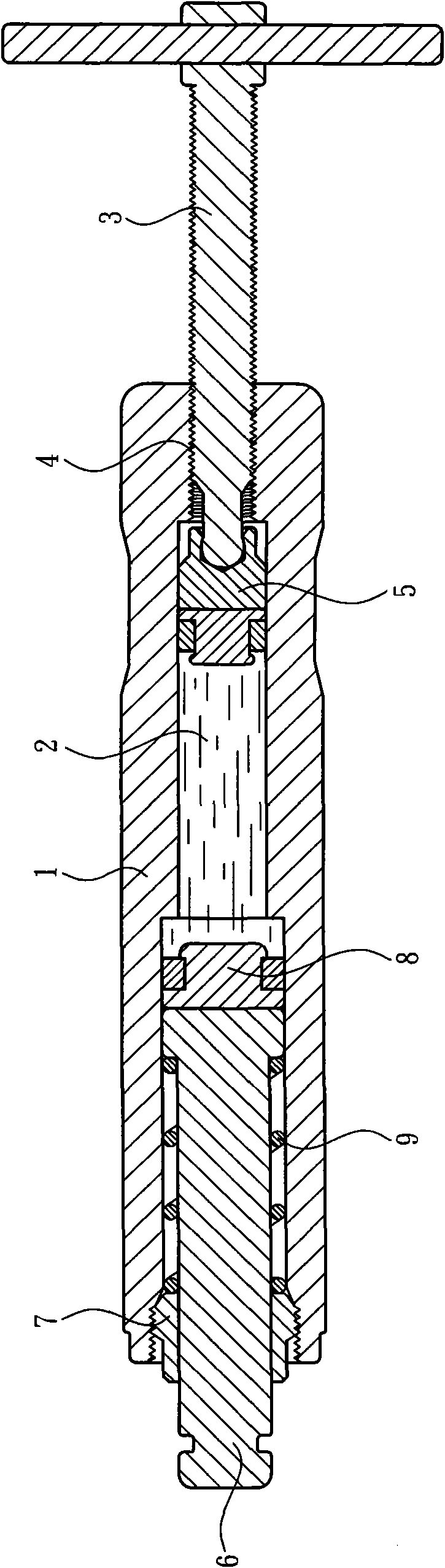

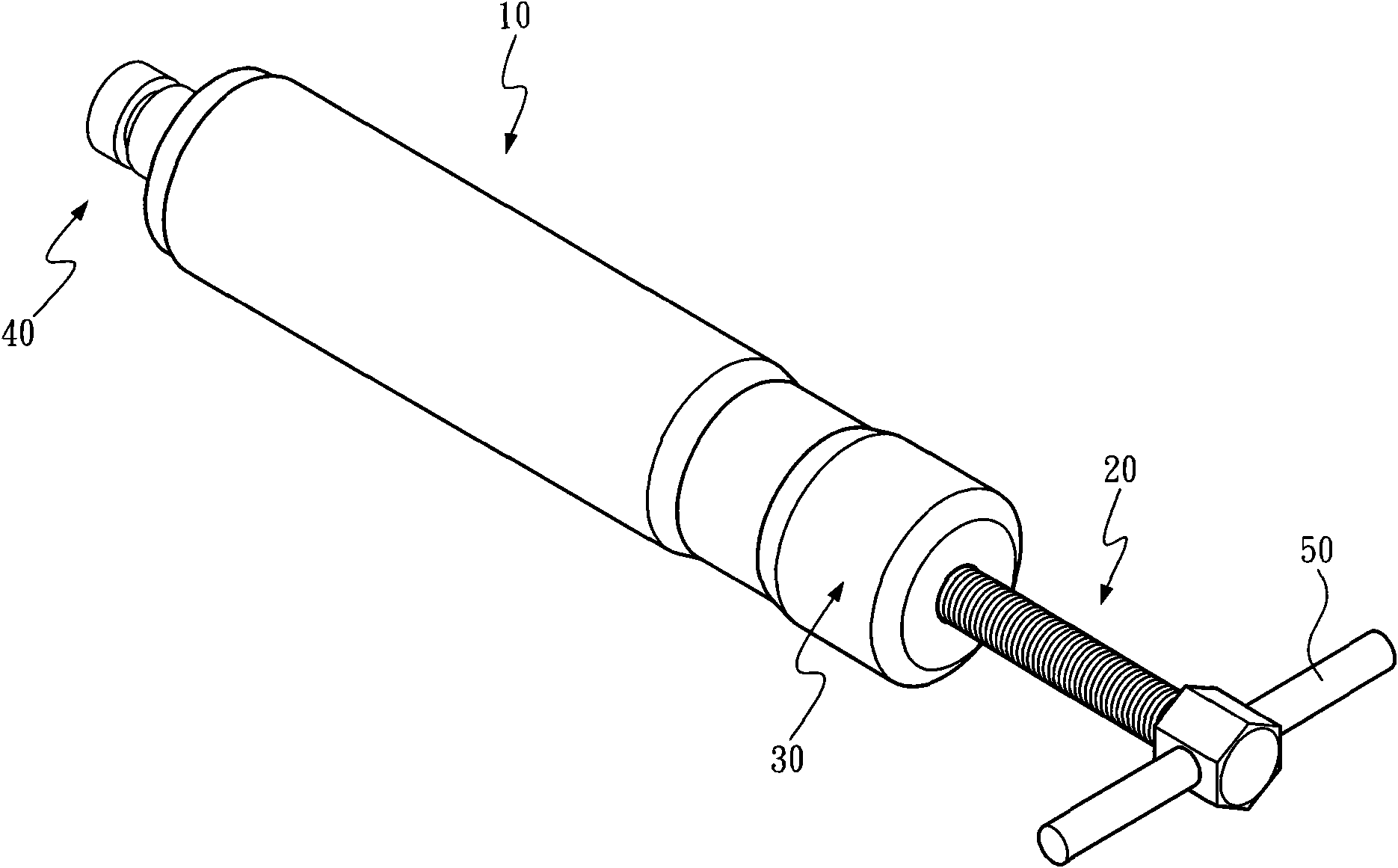

[0034] Such as Figure 2 ~ Figure 4 As shown in the drawing, the present invention is an oil pressure rod device of a manual power tool, which mainly includes:

[0035] An oil pressure rod main body 10 has a through hydraulic oil tank 11 inside, the hydraulic oil tank 11 can store hydraulic oil, and the two ends of the oil pressure rod main body 10 are respectively an input end 12 and an output end 13; The outer edge ring of the input end 12 is provided with an engaging thread segment 121;

[0036] An input shaft 20, which passes through the input end 12, an input piston 21 is provided at one end of the input shaft 20 opposite to the hydraulic oil tank 11, and at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com