Filling equipment convenient to operate

A filling equipment, filling head technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of normal use, unscientific, time-consuming, etc., and achieve the effect of fast response, accurate response and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are further described.

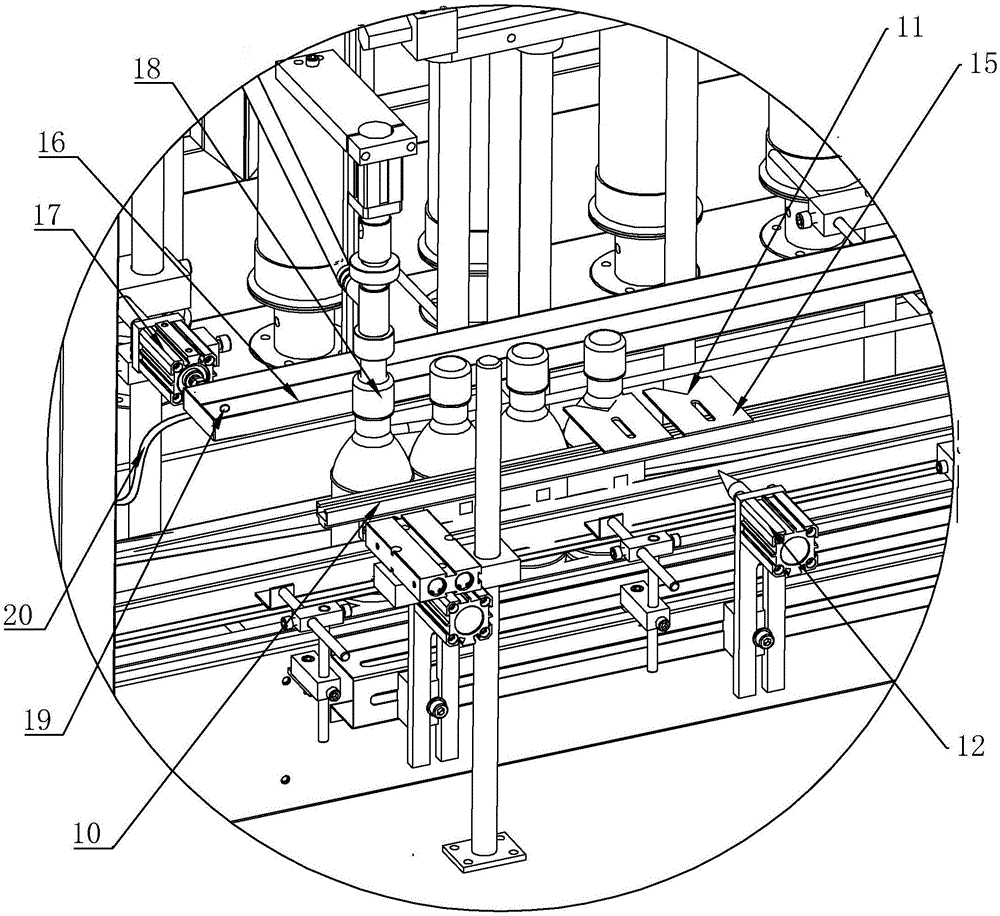

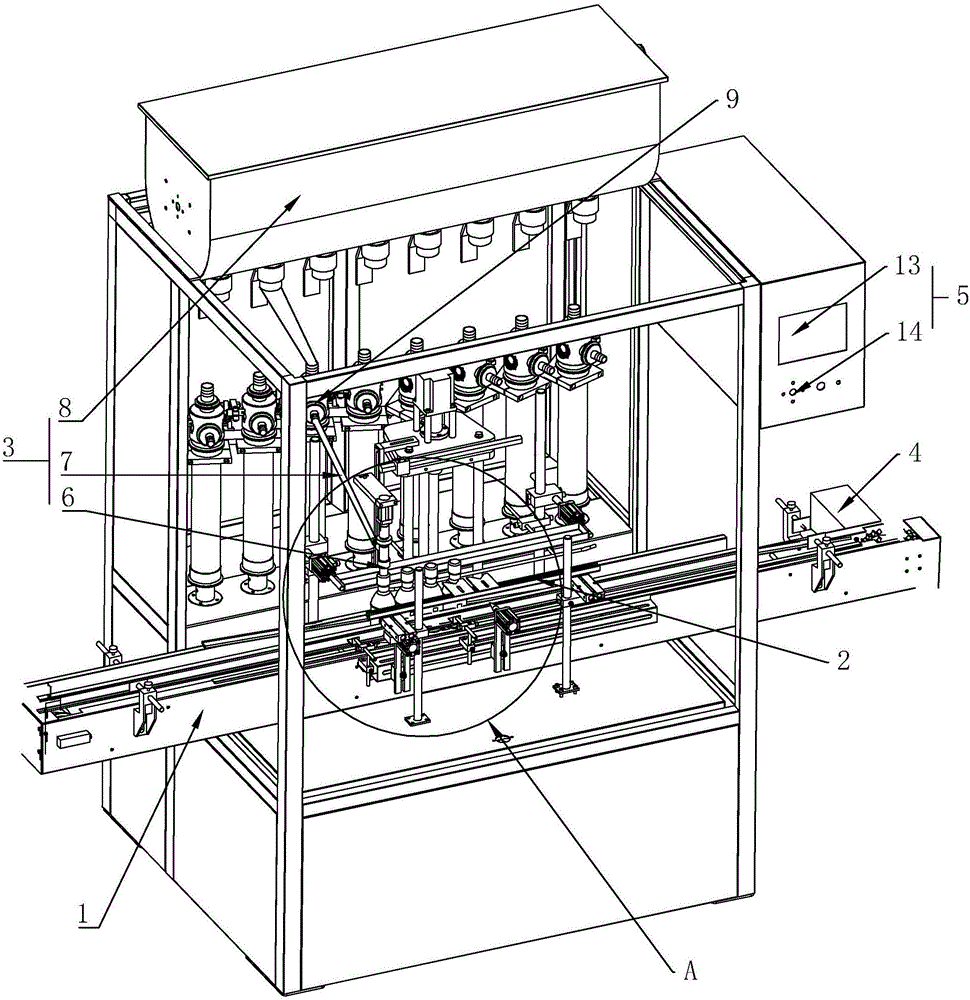

[0027] The present invention designs the following technical solutions: an easy-to-operate filling equipment, the filling equipment includes a frame, the frame is provided with a conveyor 1, a clamping device 2, a filling device 3, a weighing device 4 and a display The control device 5, wherein the liquid storage bottle is conveyed to the bottom of the filling device 3 through the conveying device 1, and the filling operation is carried out after being clamped by the clamping device 2, and the weighing device 4 weighs the weight of the liquid storage bottle before and after the filling operation The data is transmitted to the display control device 5, the display control device 5 displays the corresponding data, and controls and adjusts the amount of filling liquid output by the filling device 3, wherein the filling head 6 is movably connected to the frame through a lifting device And the receiving tray 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com