Automated vacuum waste handling system

a waste handling system and vacuum technology, applied in the direction of liquid handling, liquid transferring devices, machines/engines, etc., can solve the problems of large volume of liquid waste generated by high-throughput screening instruments, significant and expensive losses of material and equipment, and large volume of liquid was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention relates to an automated vacuum liquid waste handling system that minimizes human contact and allows full waste vessels to be emptied automatically at any time of the day, without requiring an operator to be present.

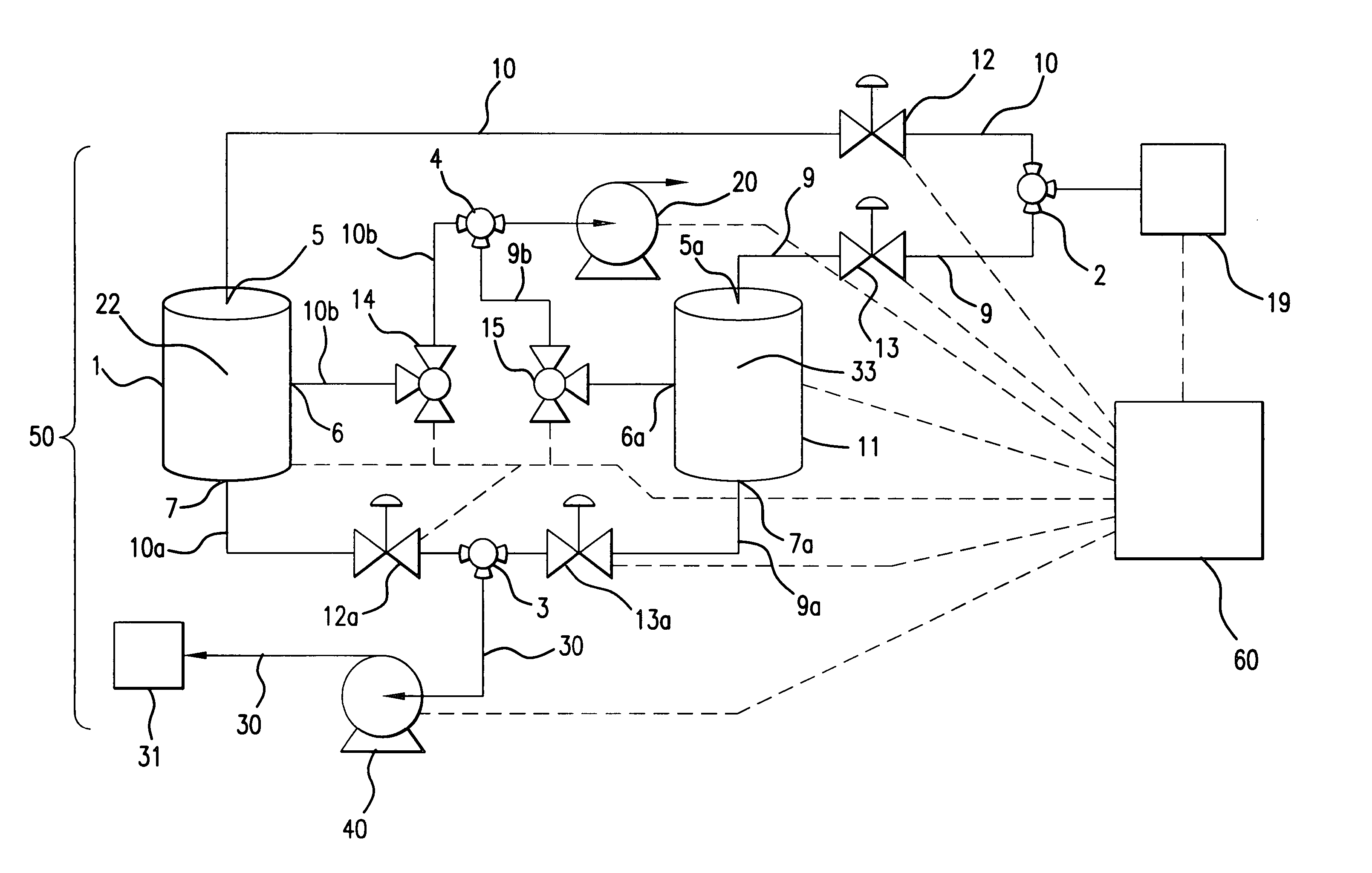

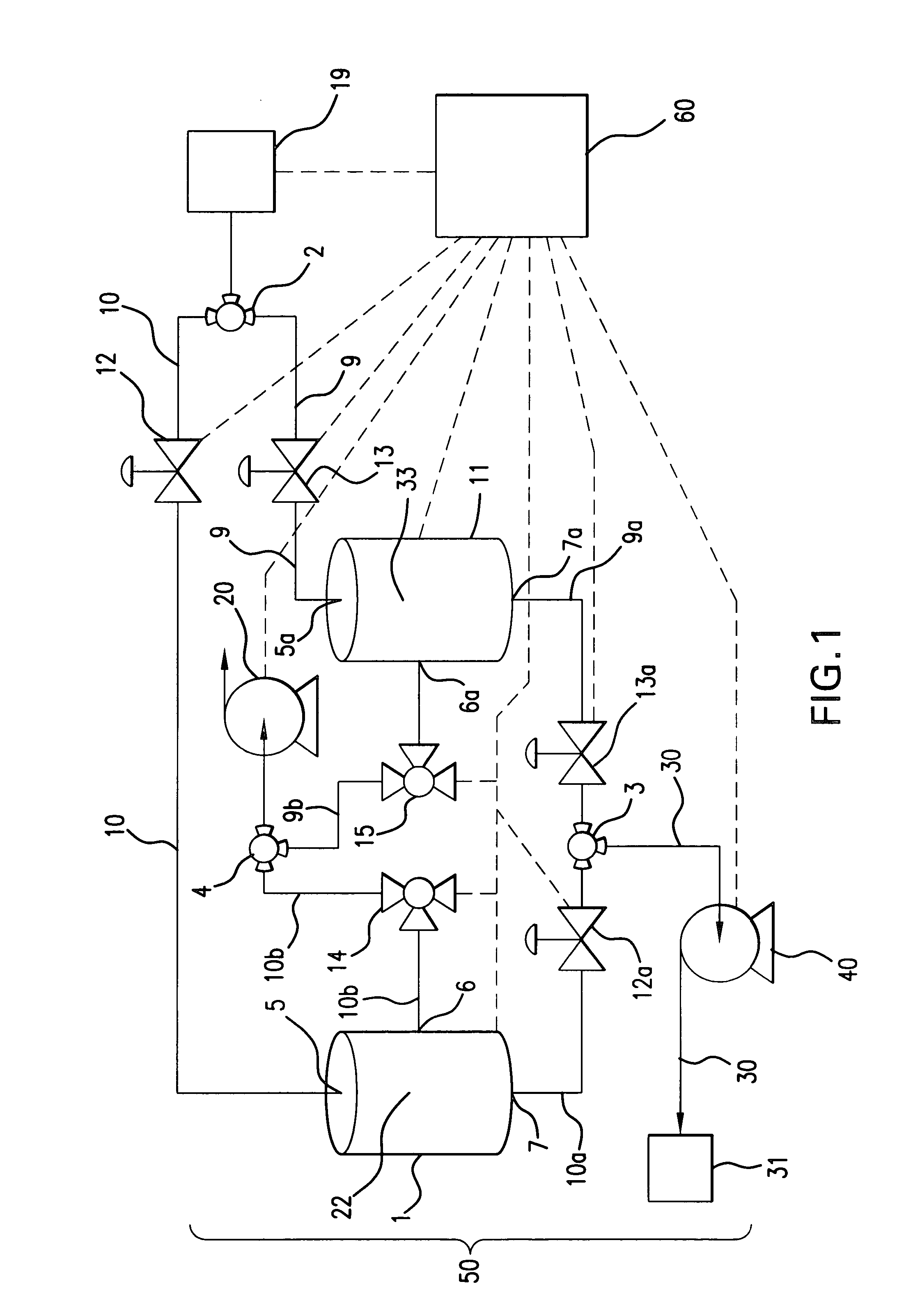

[0008] As shown in FIG. 1 (illustrating a system with 2 waste vessels), the automated vacuum waste handling system (50) comprises liquid waste production source (19), liquid waste supply lines (9) and (10) each having at least one 2-way control valve (12) and (13), liquid waste vessels (1) and (11) each having liquid-level sensors (22) and (33), respectively, and three openings (5), (6) and (7) and (5a), (6a) and (7a), respectively, liquid waste output lines (10a) and (9a) each having at least one 2-way control valve (12a) and (13a), removal pump (40), vacuum source lines (10b) and (9b), each vacuum source line having a 3-way control valve (14) and (15) attached thereto, vacuum pump (20) and T-joints (2), (3) and (4).

[0009] The liquid waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com