Mobile type liquid hazardous chemical sub-packaging device and sub-packaging method

A dangerous chemical, mobile technology, applied in liquid bottling, packaging, liquid filling, etc., to achieve the effect of ensuring safety, high degree of system automation, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail

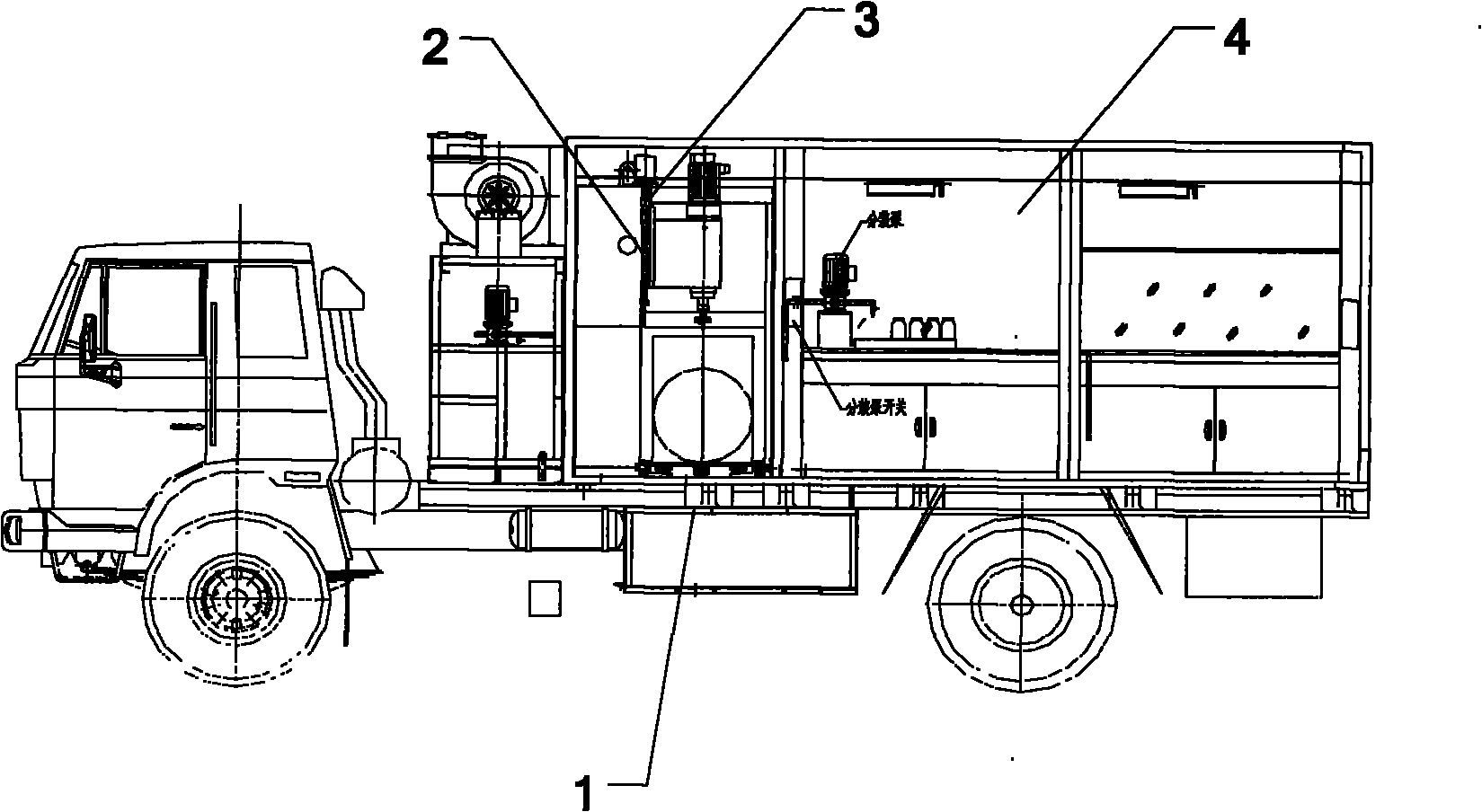

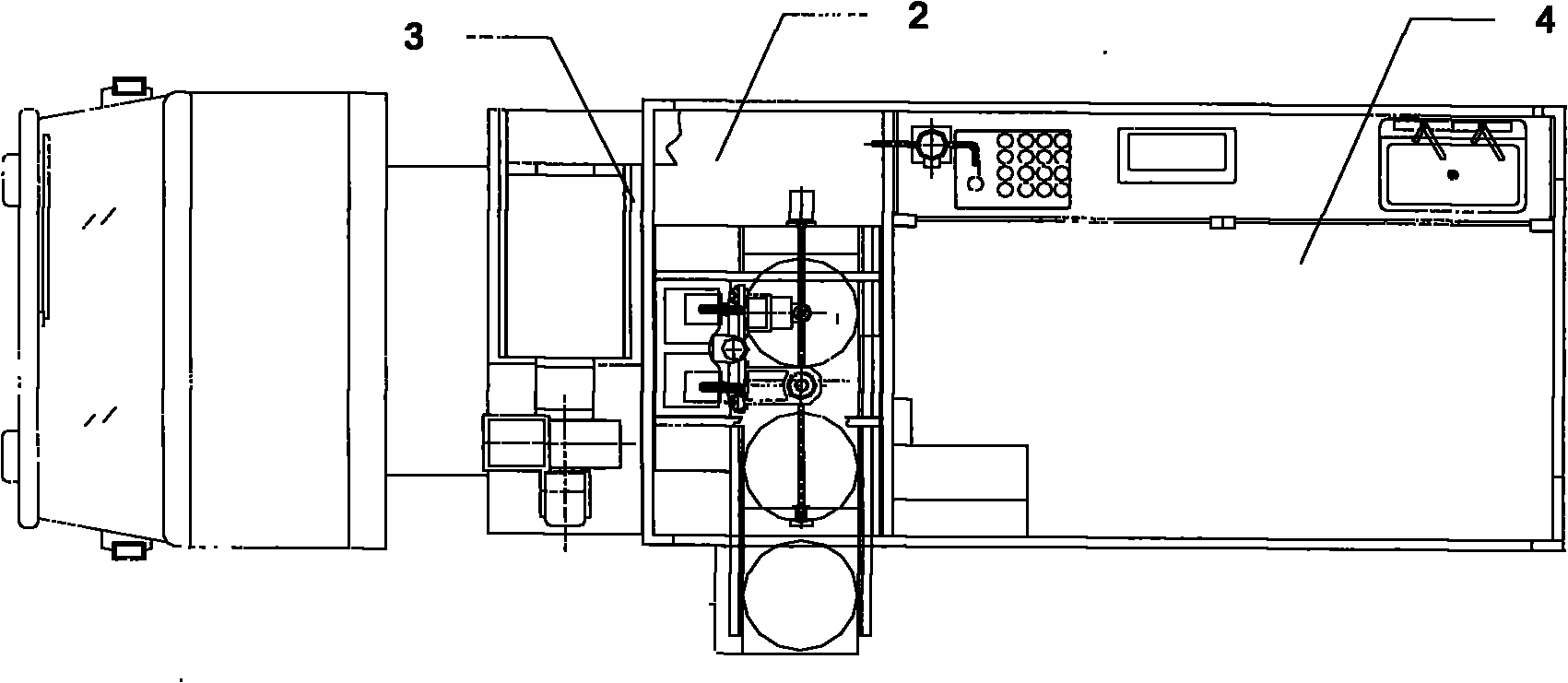

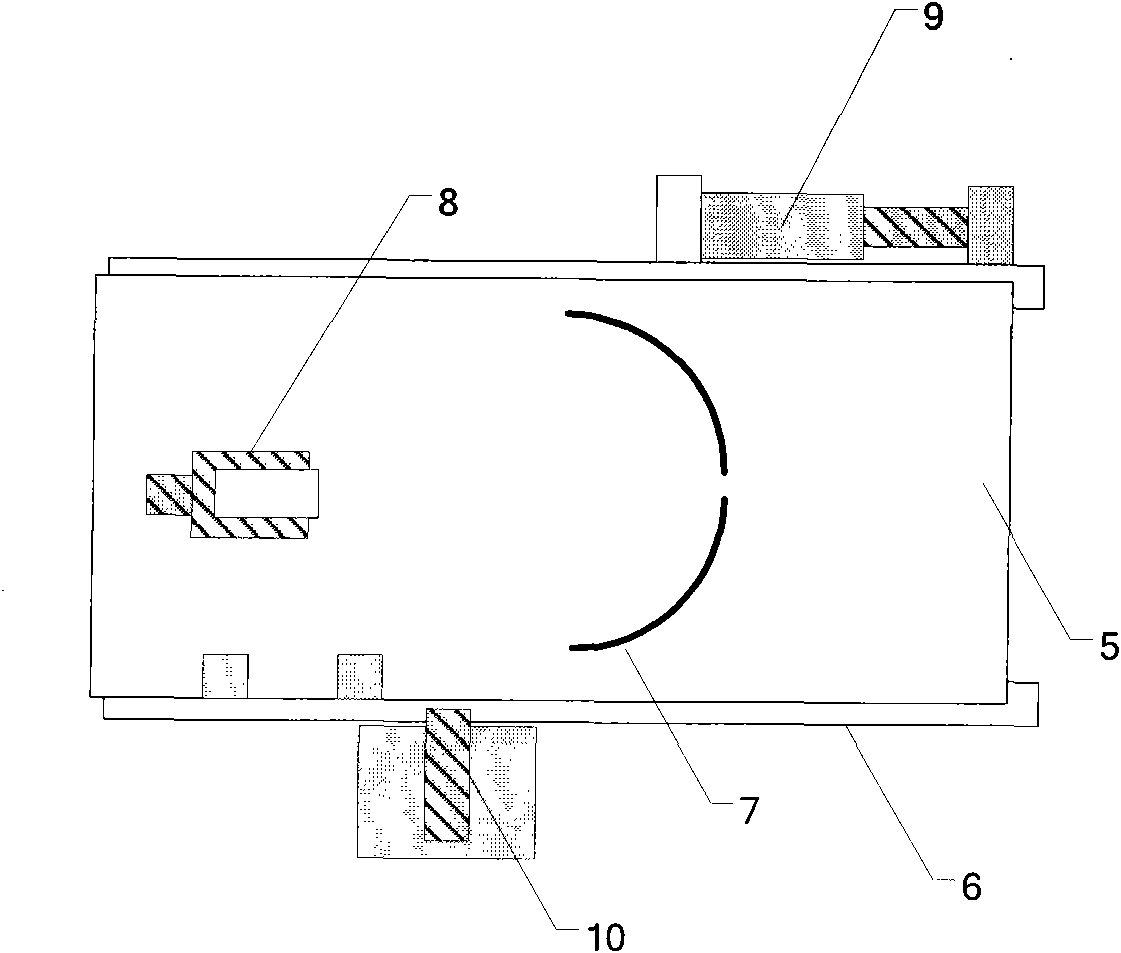

[0029] The invention relates to a mobile liquid dangerous chemical dispensing device, comprising a conveying unit, a punching unit, a straw conveying unit, and a dispensing unit. The mobile hazardous chemicals dispensing device is installed in the carriage of the vehicle. The carriage of the carriage is composed of two parts. The box body is equipped with a sub-package unit, and the front side box body and the rear side box body box are only connected by suction pipes to transport liquids, such as figure 1 , 2 shown. Among them, the transmission unit is connected with the vehicle floor 1, and is used to transmit the hazardous chemical barrel to the designated position, and the punching unit is located in the front compartment 2 of the vehicle for loading the mobile hazardous chemical packaging device, and the punching unit is The unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com