Method and equipment for vacuum quantitative filling of filling and sealing machine

A filling and sealing machine and vacuum technology, applied in the field of mechanical equipment, can solve the problems of unresolved precise quantitative filling, etc., and achieve the effects of easy disassembly, large processing capacity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

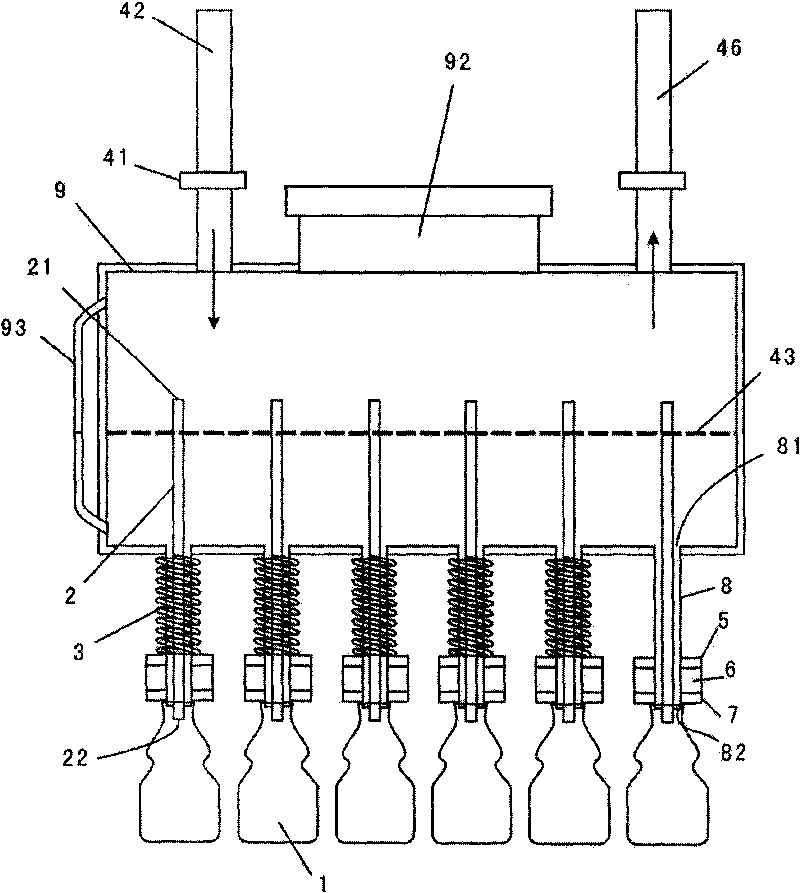

[0100] A base plate 74 supports a hydraulic / pneumatic cylinder 71 having an internal 712 and an external 711 .

[0101] The hydraulic / pneumatic cylinder 71 is connected to the bottle ejecting plate 72, and the hydraulic / pneumatic cylinder 71 is controlled to press out or retract according to the instructions of the central controller 10, that is, the filling bottle 1 is ejected or retracted from the bottle holding plate 61. retract.

[0102] Such as Figure 4 As shown, a button group 30 can accept instructions from the operator to make the whole device work in various states.

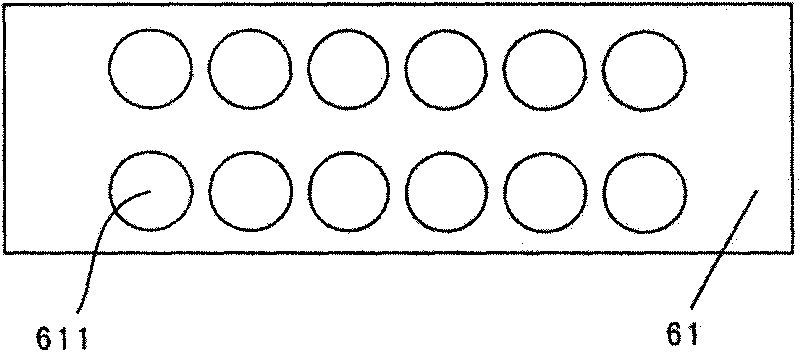

[0103] Such as Figure 5 As shown, a plurality of bottle-holding plates 61 are connected to the transmission chain (not shown in the figure), and the bottle-holding plate driver 60 drives the transmission chain to run.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com