Liquid fertilizer filling machine

A liquid fertilizer and filling machine technology, applied in the field of mechanical devices, can solve the problems of easy pollution of the working environment, waste, liquid fertilizer splashing, etc., and achieve the effect of protection from pollution, simple structure, and elimination of waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

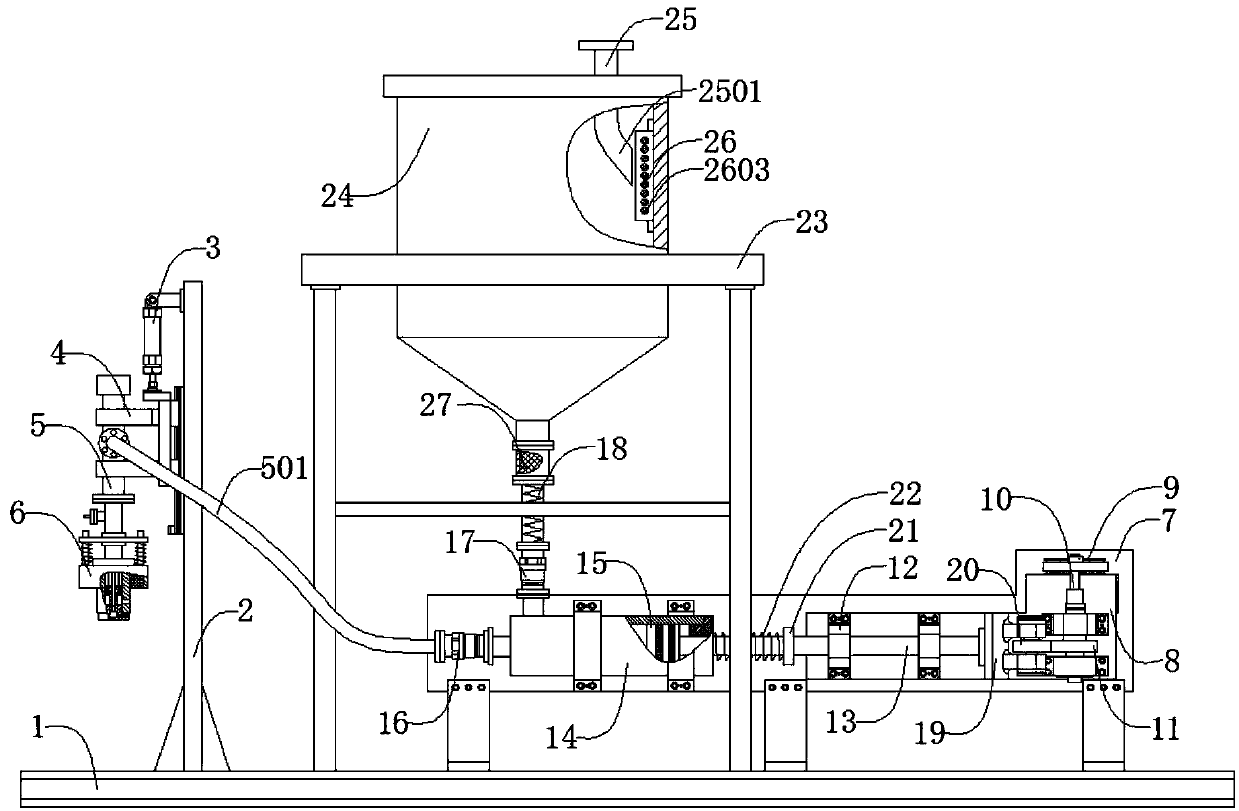

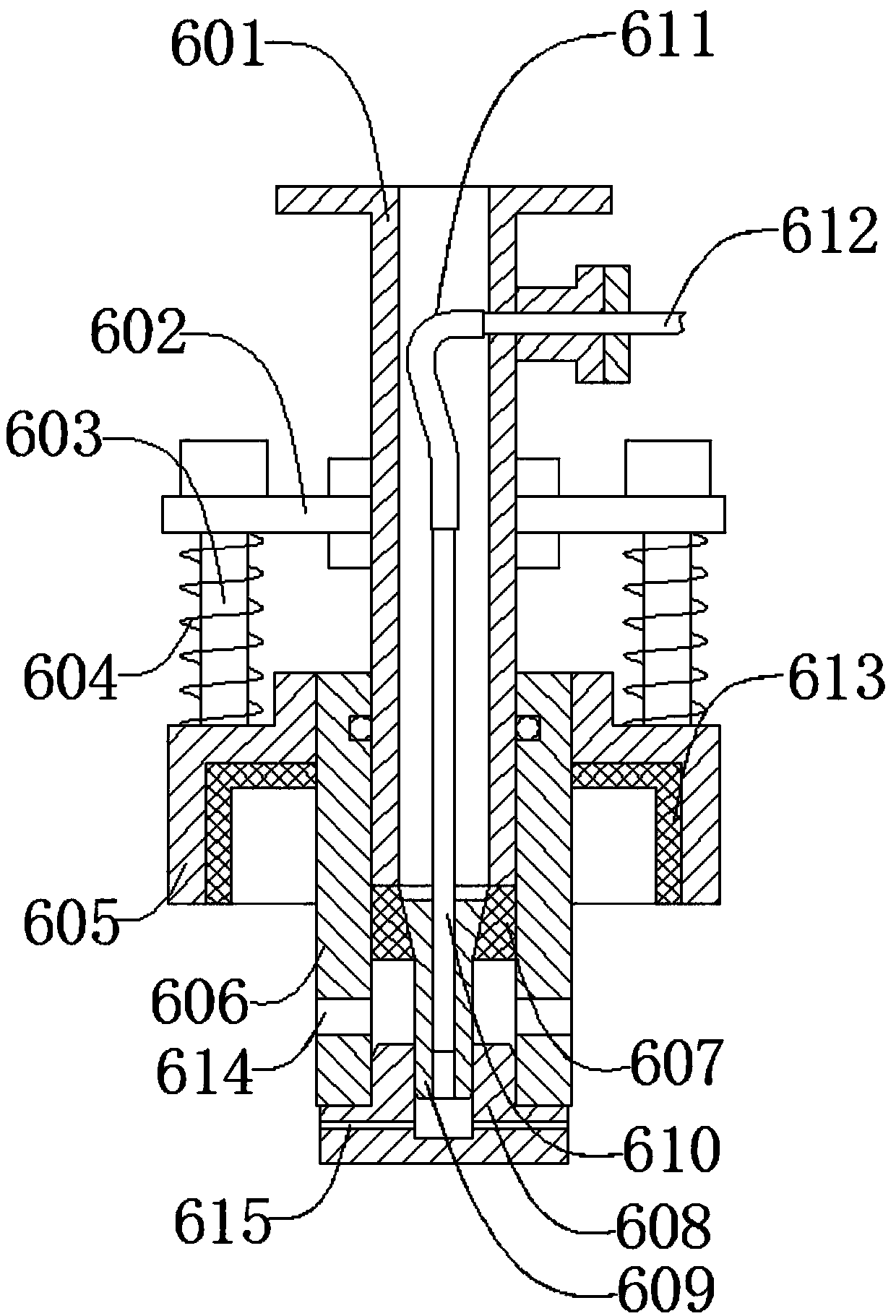

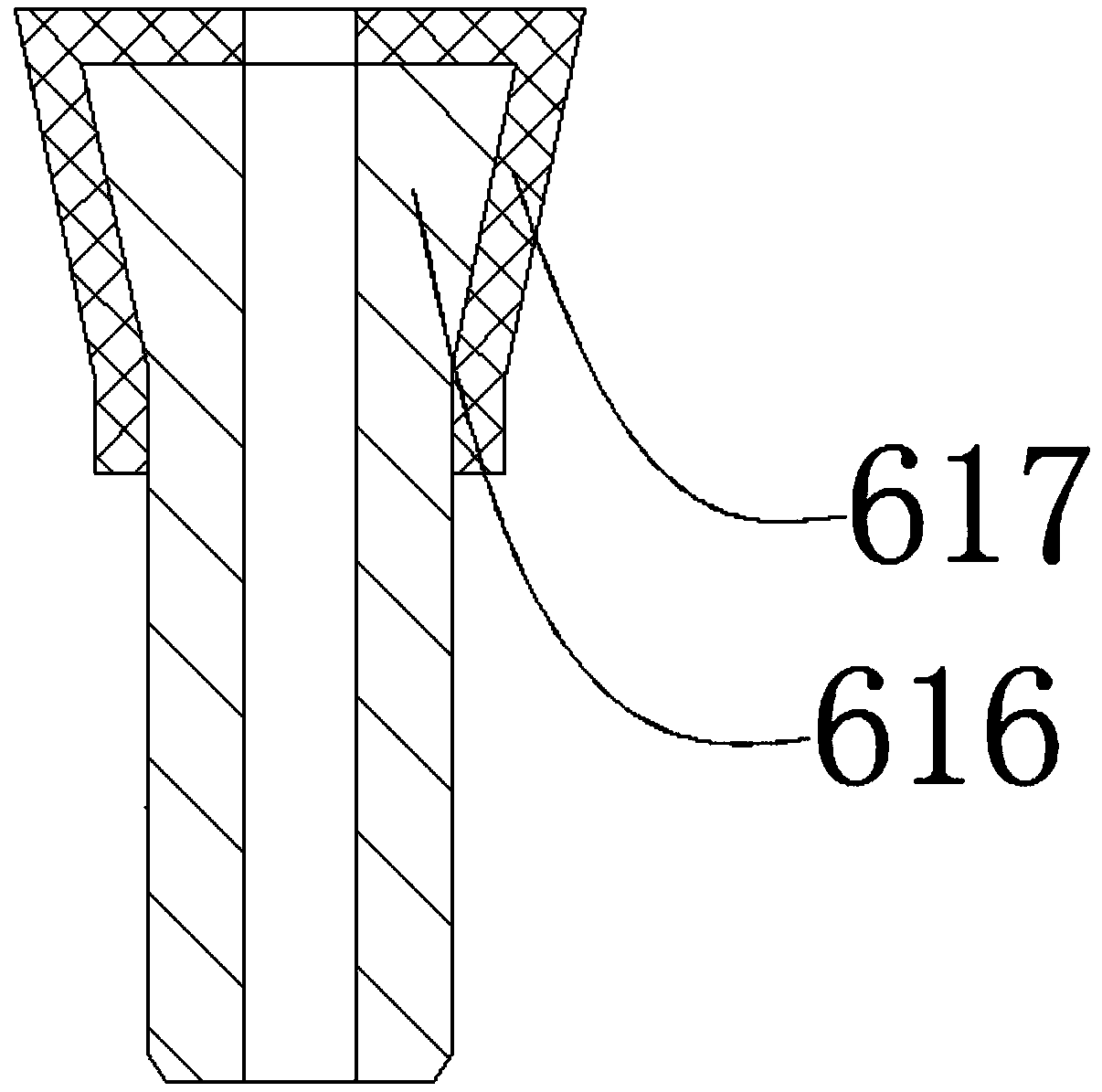

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a liquid fertilizer filling machine includes a base 1, a stand 2, a cylinder 3, a slide 4, a filling pipe 5, a filling head 6, a vertical plate 7, a supporting plate 8, a driving mechanism 9, and a rotating shaft 10 , cam 11, guide sleeve 12, push rod 13, cylinder 14, piston 15, first one-way valve 16, second one-way valve 17, soft connection 18, Sliding plate 19, guide wheel 20, stop ring 21, first spring 22, support 23, barrel 24, the liquid inlet pipe 25 that is provided with elbow 2501, buffer mechanism 26, filter mechanism 27, described stand 2 is located on the left side of the upper end of the base 1, the stand 2 is screwed to the base 1, the cylinder 3 is located on the left side of the stand 2, the cylinder 3 is hinged to the stand 2, and the slide 4 Located at the lower end of the cylinder 3 and on the left side of the stand 2, the slide 4 is threadedly connected with the cylinder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com