Machine for sealing carton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

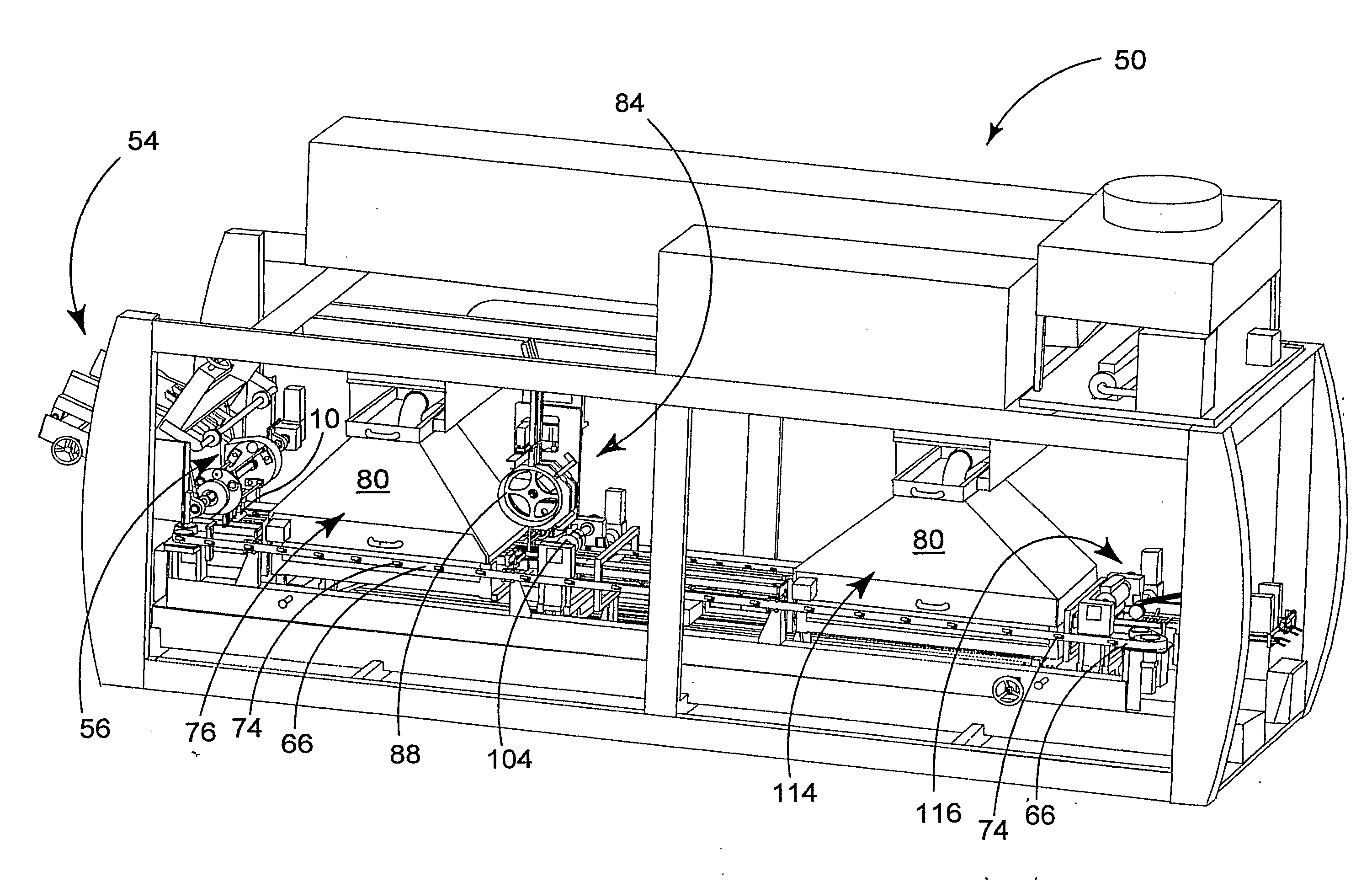

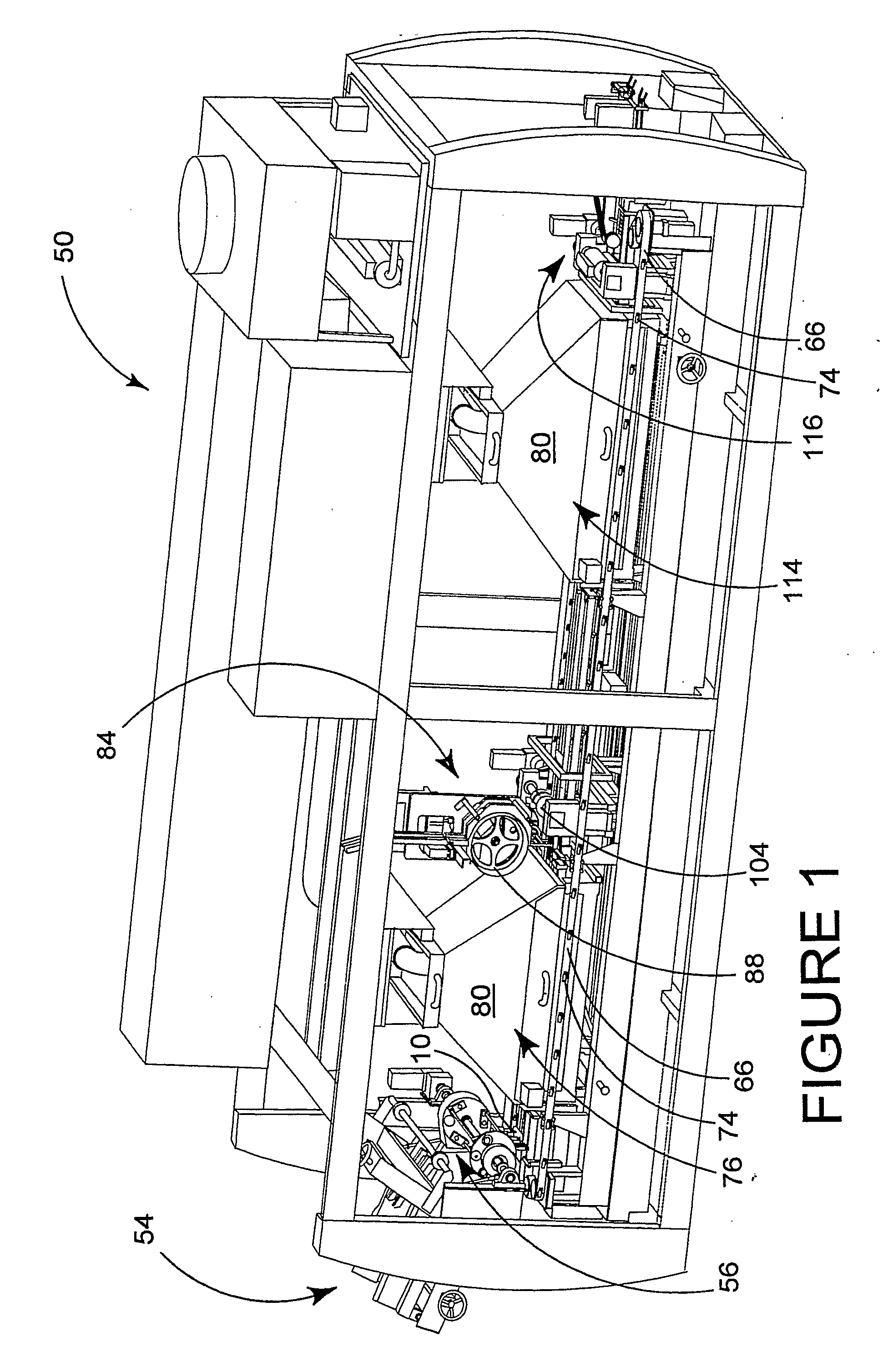

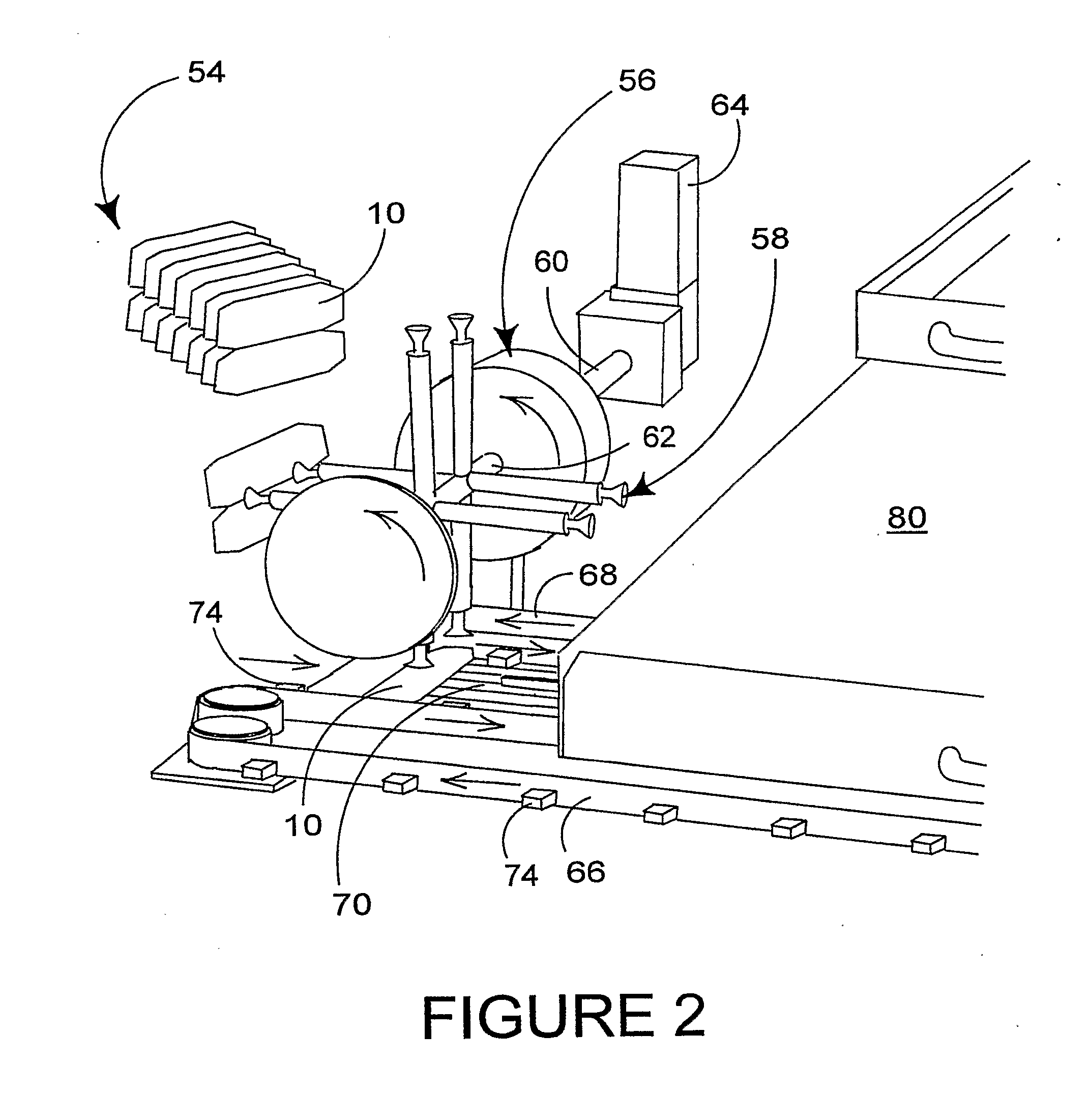

[0055]The present invention provides a packaging machine which can condition a surface of a continually moving substrate in preparation of adhering one or both surfaces of the substrate to a second substrate. Particularly the packaging machine 50 of the preferred embodiment of the invention can reactivate an adhesive agent provided on a substrate, such as a paperboard carton blank10. The packaging machine 50, as shown in FIG. 1 conditions the continuously moving blank 10, using heat, and can also perform a series of folding and compression steps which may be required to construct a carton or other sealed item from the blank or substrate 10.

[0056]Referring to the drawings, there is shown in FIG. 6 one example of a blank 10, formed from paperboard or other suitable material, for forming a carton to be constructed and loaded by a packaging machine 50 of one or more aspects of the present invention. The paperboard blank 10 may be impregnated or coated on one or more sides by a heat reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com