Method for closing containers by means of a closure in a gripping device

a technology a closure is applied in the field of closing containers by means of a gripper device, which can solve the problems of imposing considerable expense on the part size of the closure, and the prior art method does not allow flexible design of the workflow, so as to achieve simple and efficient flow, save production time, and reduce the effect of manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

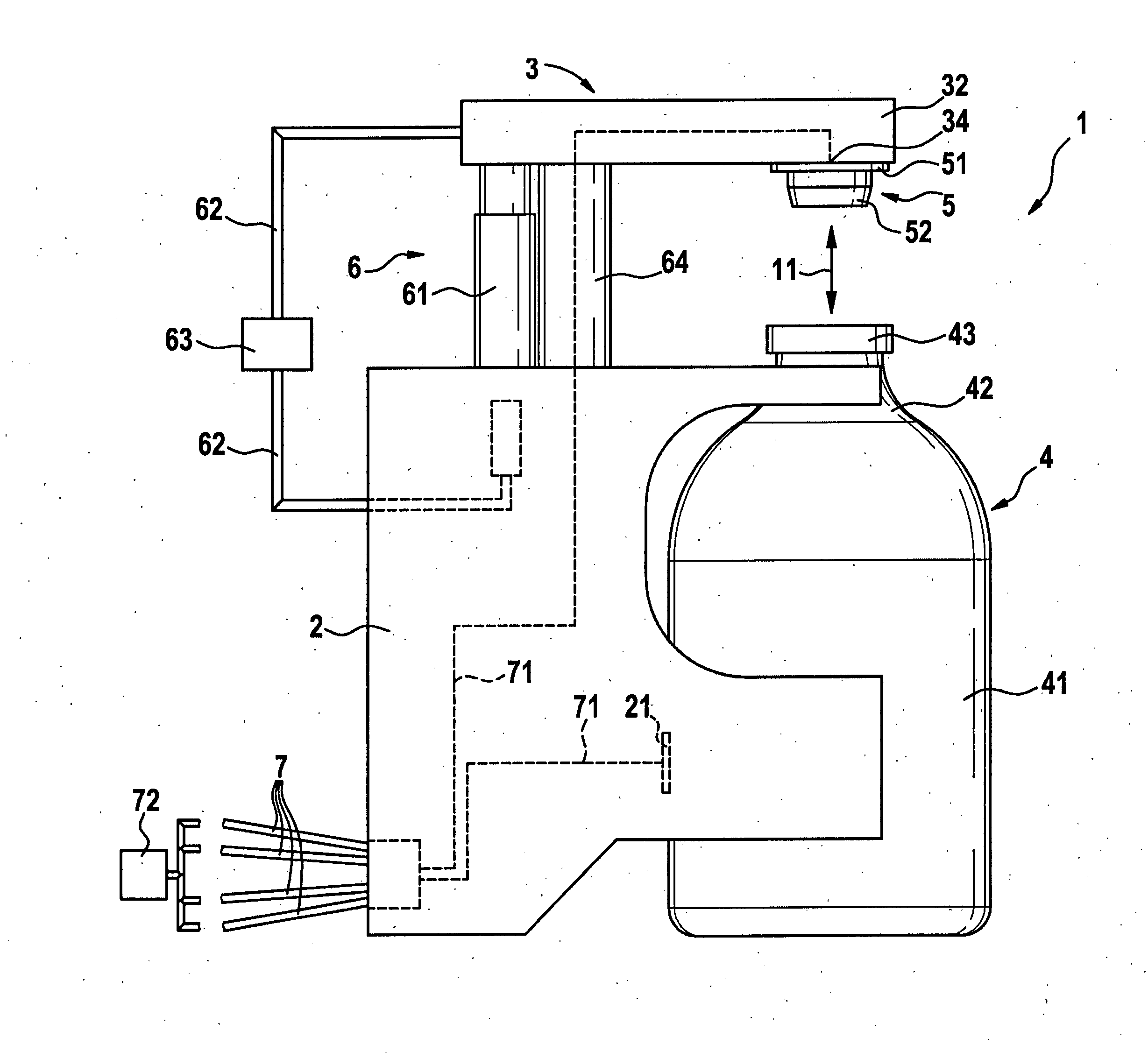

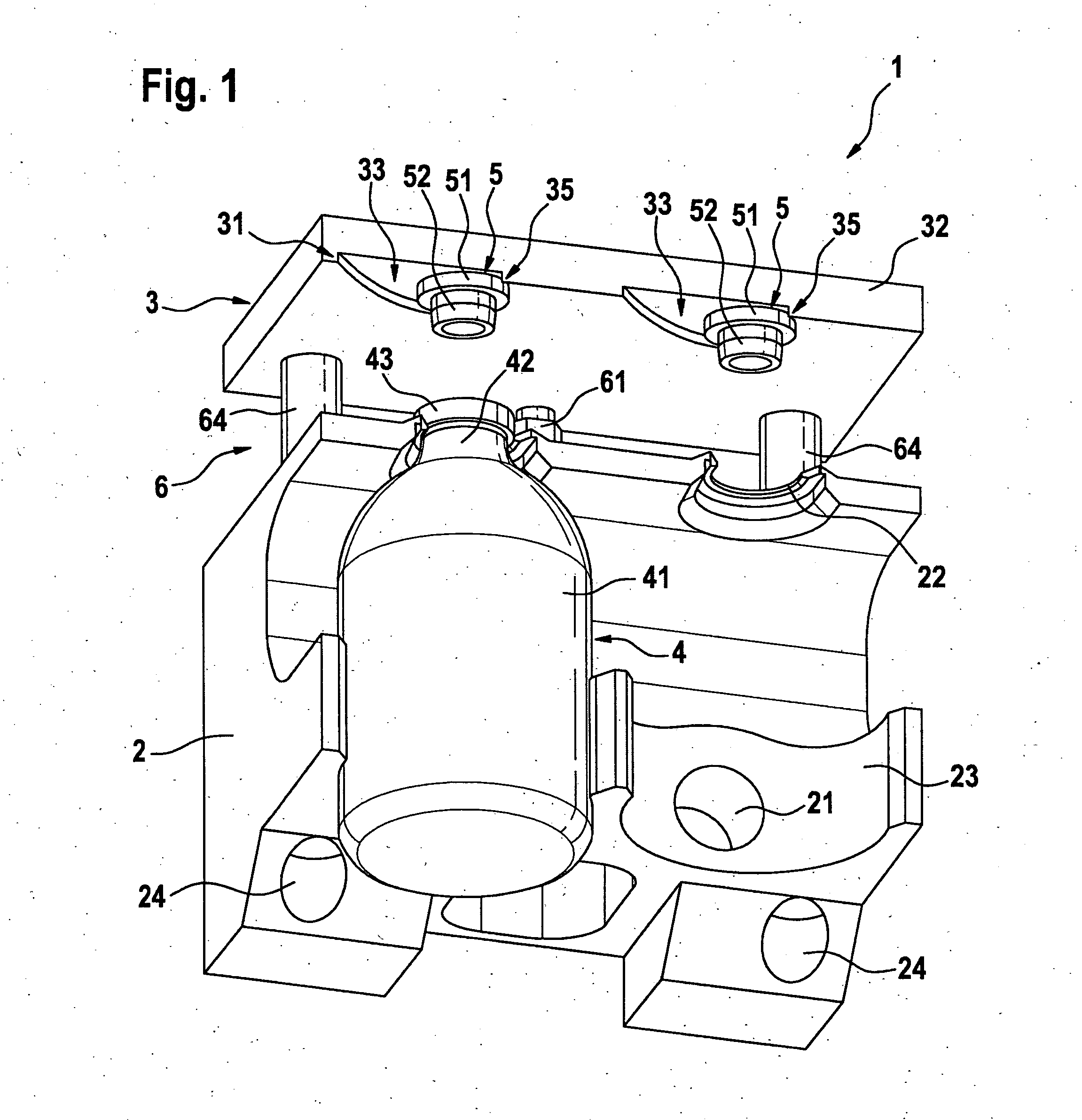

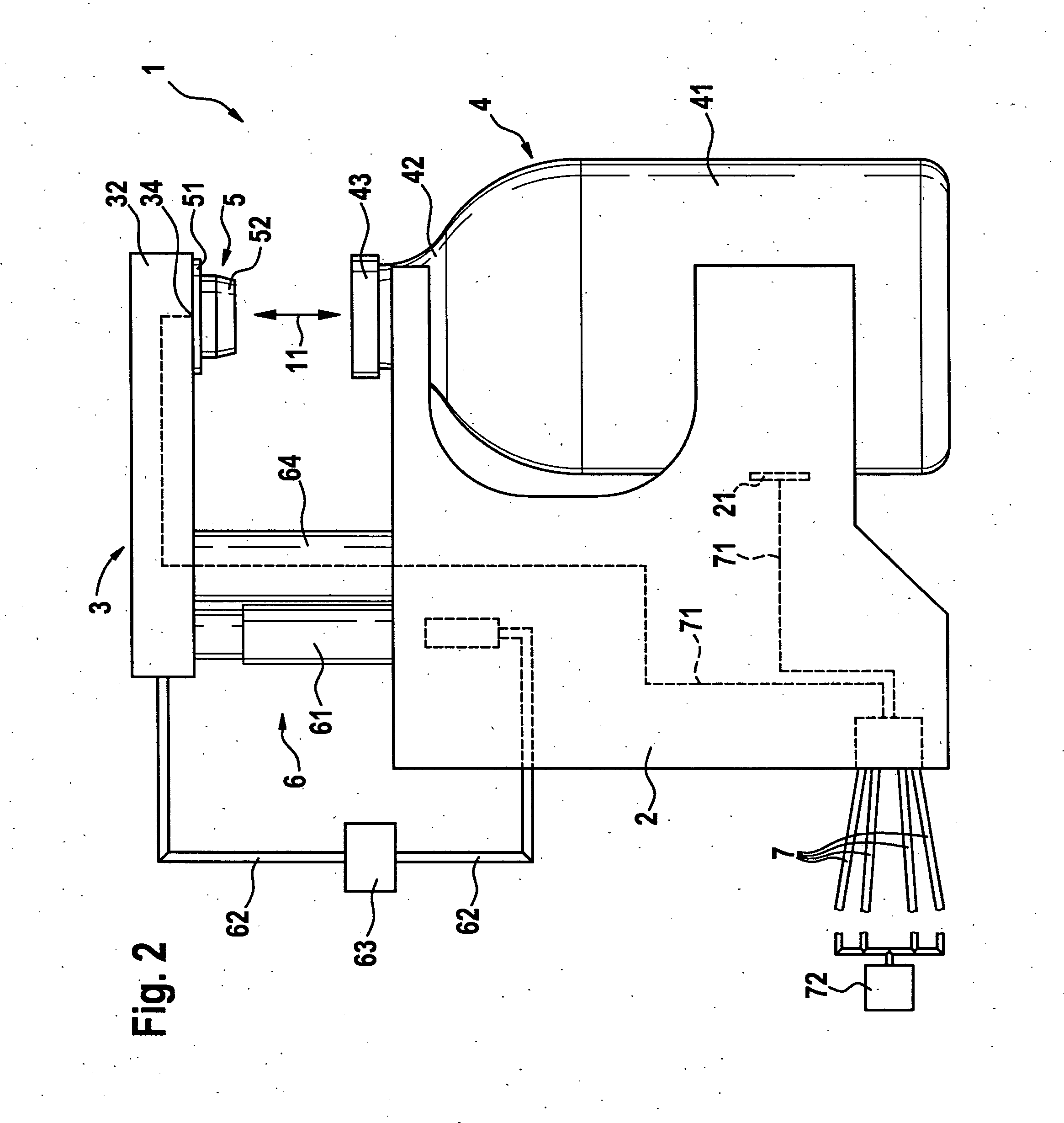

[0023]Below, in conjunction with FIGS. 1 through 3, a gripper device 1 for performing a method in accordance with a preferred exemplary embodiment of the invention will be described in detail. The gripper device 1 of the exemplary embodiment is used with a manipulation unit 81 within a pharmaceutical system 8.

[0024]As can be seen from FIG. 1, the gripper device 1 includes a container receptacle 2, a closure receptacle 3, and connecting elements 6. As will be described in conjunction with the pharmaceutical system 8 in FIG. 3, this gripper device 1 can pick up two containers 4 and two closures 5 and transport them. The two containers 4 are closed with the closures 5 while being transported. It should be noted here that depending on the required yield of the pharmaceutical system 8, the gripper device 1 can also be embodied according to the invention for only one or for more than two containers 4. Moreover, the invention is not limited to the use of round, bottle-like containers 4. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com