Vacuum-pumping and nitrogen-filling plug-adding apparatus

A plugging device and vacuum pumping technology, which is applied in the direction of pressurized/vaporized packaging, packaging, screwless plugs, etc., can solve the problems of complex structure of the device, high production cost, liquid pollution, etc., and achieve simple and compact structure, improve quality The effect of high efficiency and convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

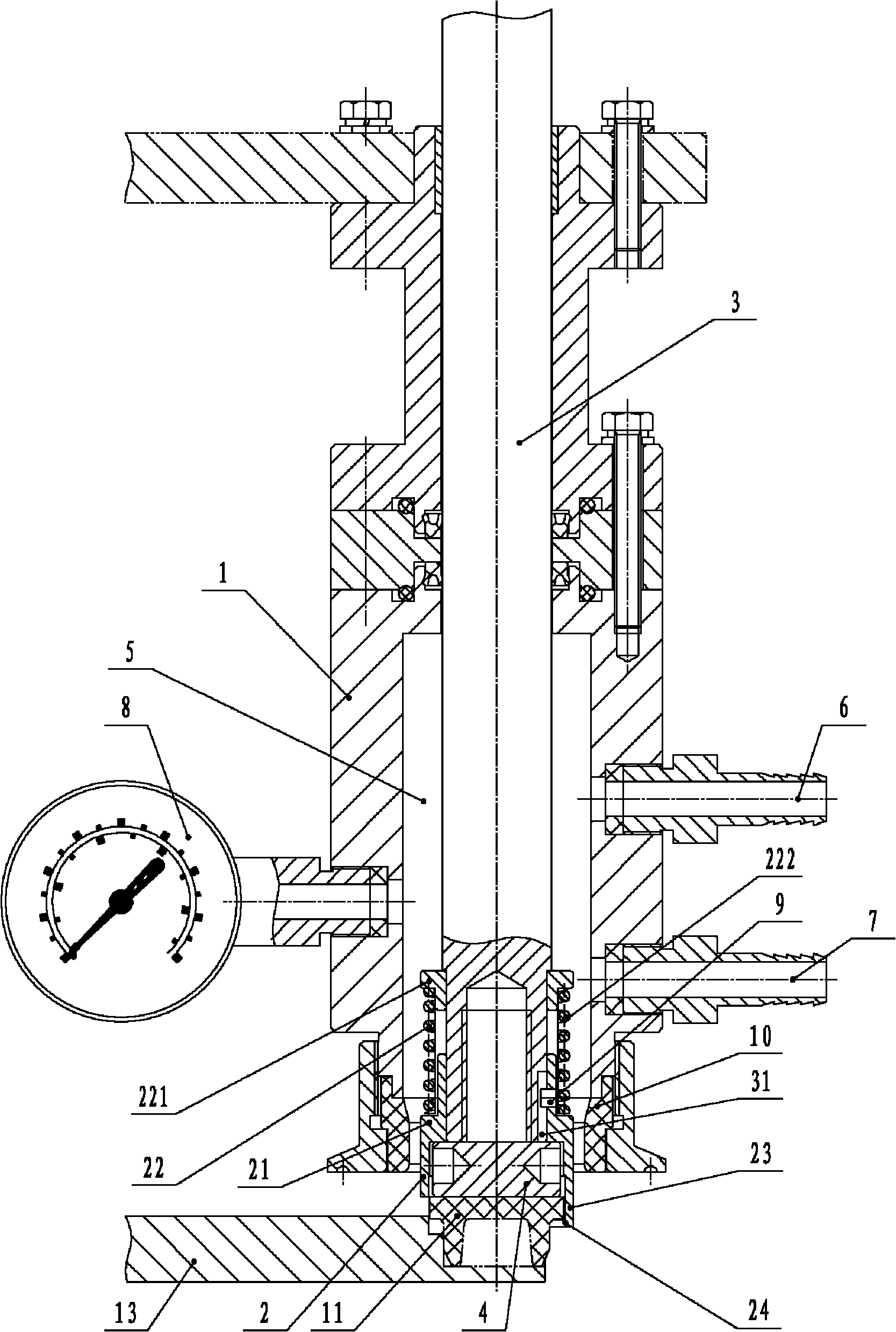

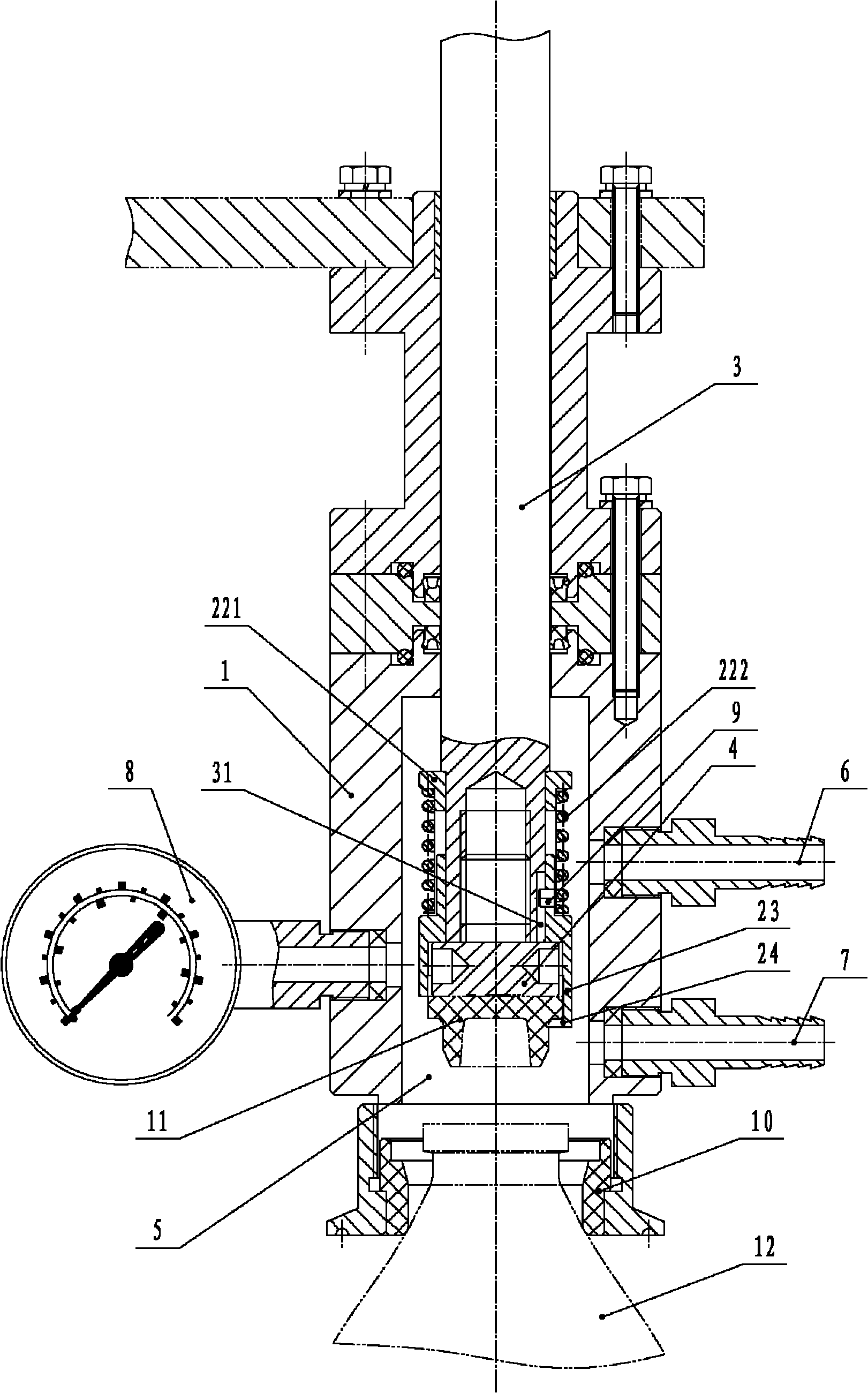

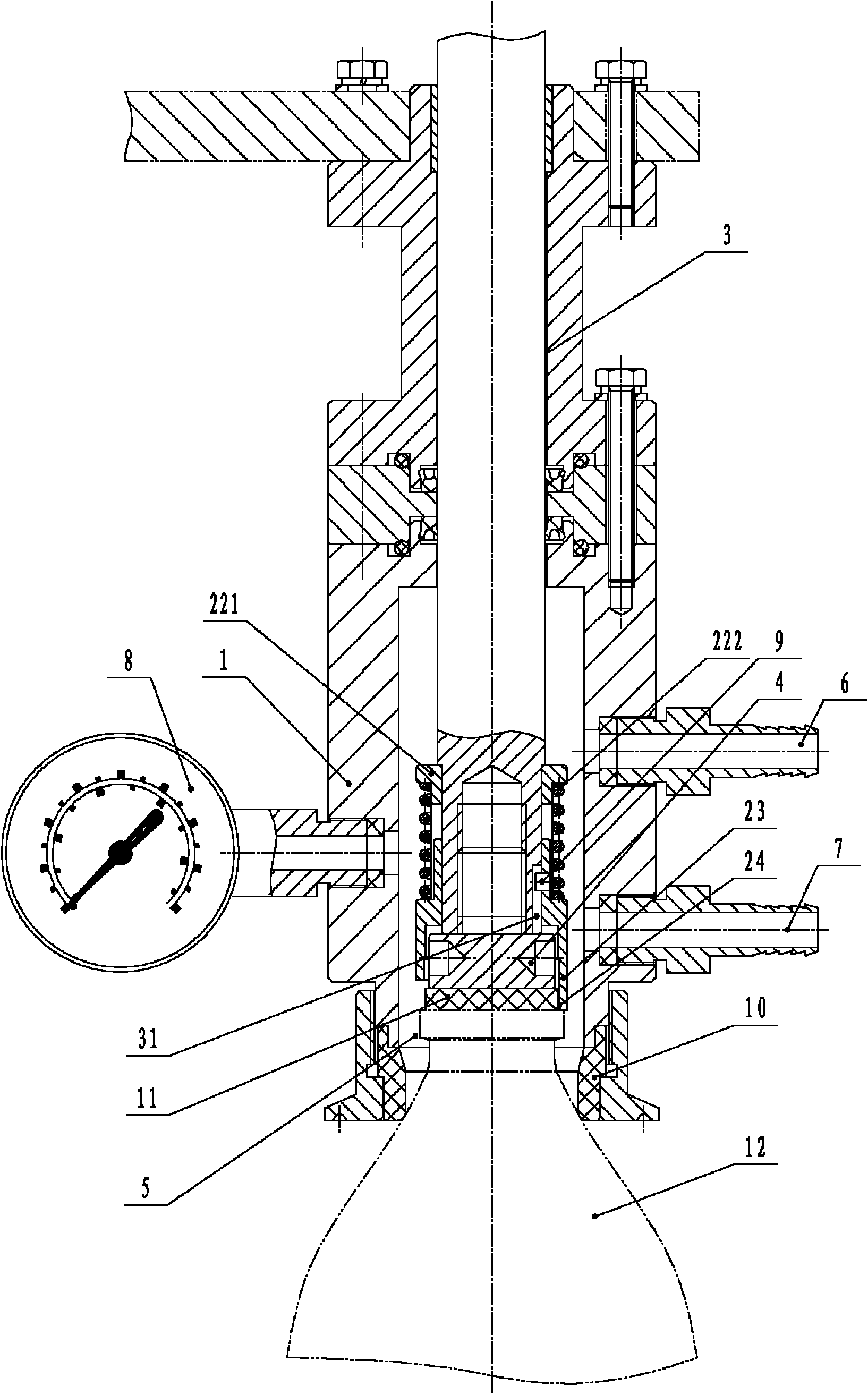

[0022] Figure 1 to Figure 5 Shown is a vacuum pumping nitrogen plugging device of the present invention, including a lifting shaft 3 and a connecting sleeve 1 having a vacuum pumping nitrogen filling chamber 5, and a pressure gauge 8 communicating with the chamber 5, a vacuum chamber 5, and a pressure gauge 8 are installed on the connecting sleeve 1. The joint 6 and the nitrogen joint 7, the lifting shaft 3 is socketed with the connecting sleeve 1, and the lower part of the lifting shaft 3 is placed in the evacuated and nitrogen-filled chamber 5, so that the mouth of the bottle 12 to be processed is sealed in the chamber 5 to Carry out vacuuming and nitrogen filling, the lower end of connecting sleeve 1 is equipped with sealing sleeve 10 that can be in sealing contact with bottle body 12 bottlenecks, in order to ensure the tightness of chamber 5, a sealing ring is provided between lifting shaft 3 and connecting sleeve 1. The lower end of the lifting shaft 3 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com