Top-emitting light emitting diodes and method of manufacturing thereof

A light-emitting device and interface technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of deterioration of electrical characteristics of light-emitting devices, low luminous efficiency of diodes, lack of highly transparent electrode materials, etc., to improve luminous efficiency and device life, Excellent current-voltage characteristics, the effect of improving ohmic contact characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, a top emission nitride-based light emitting device according to a preferred embodiment of the present invention will be described in more detail with reference to the accompanying drawings.

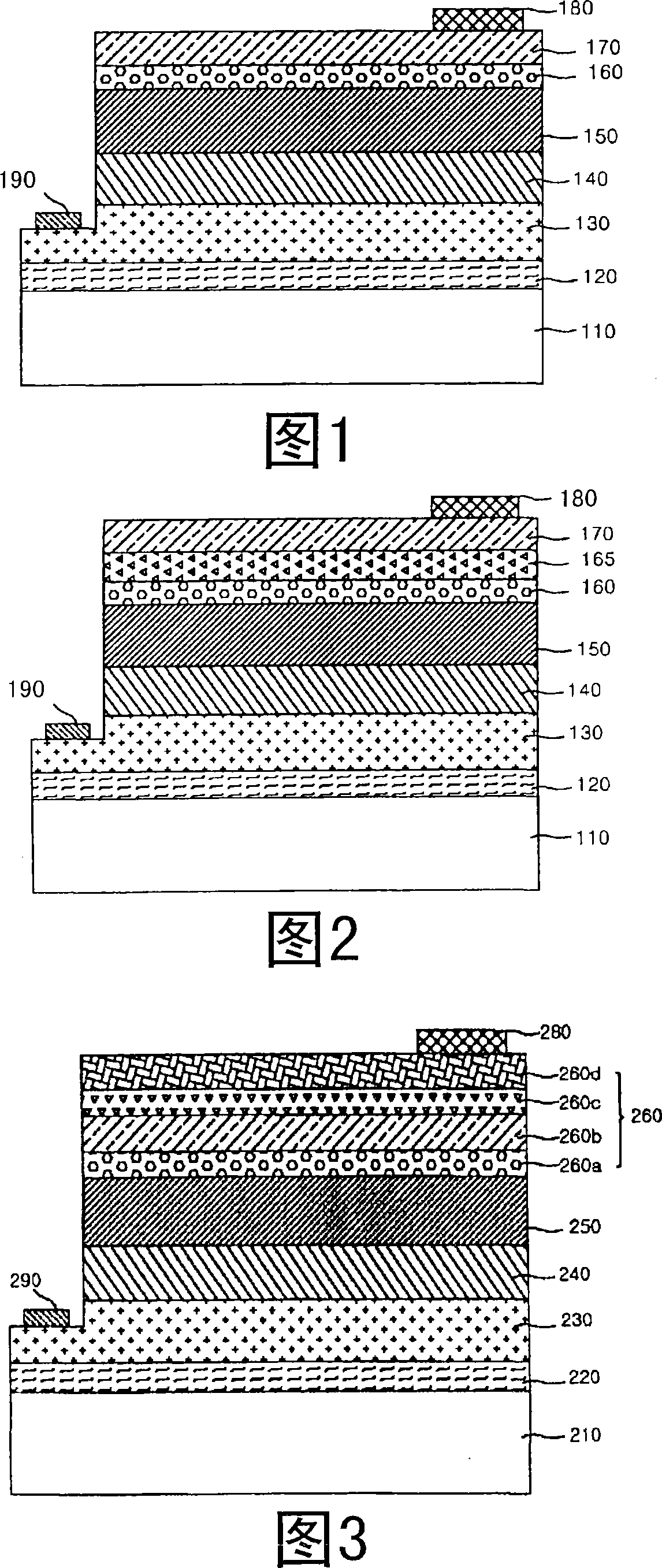

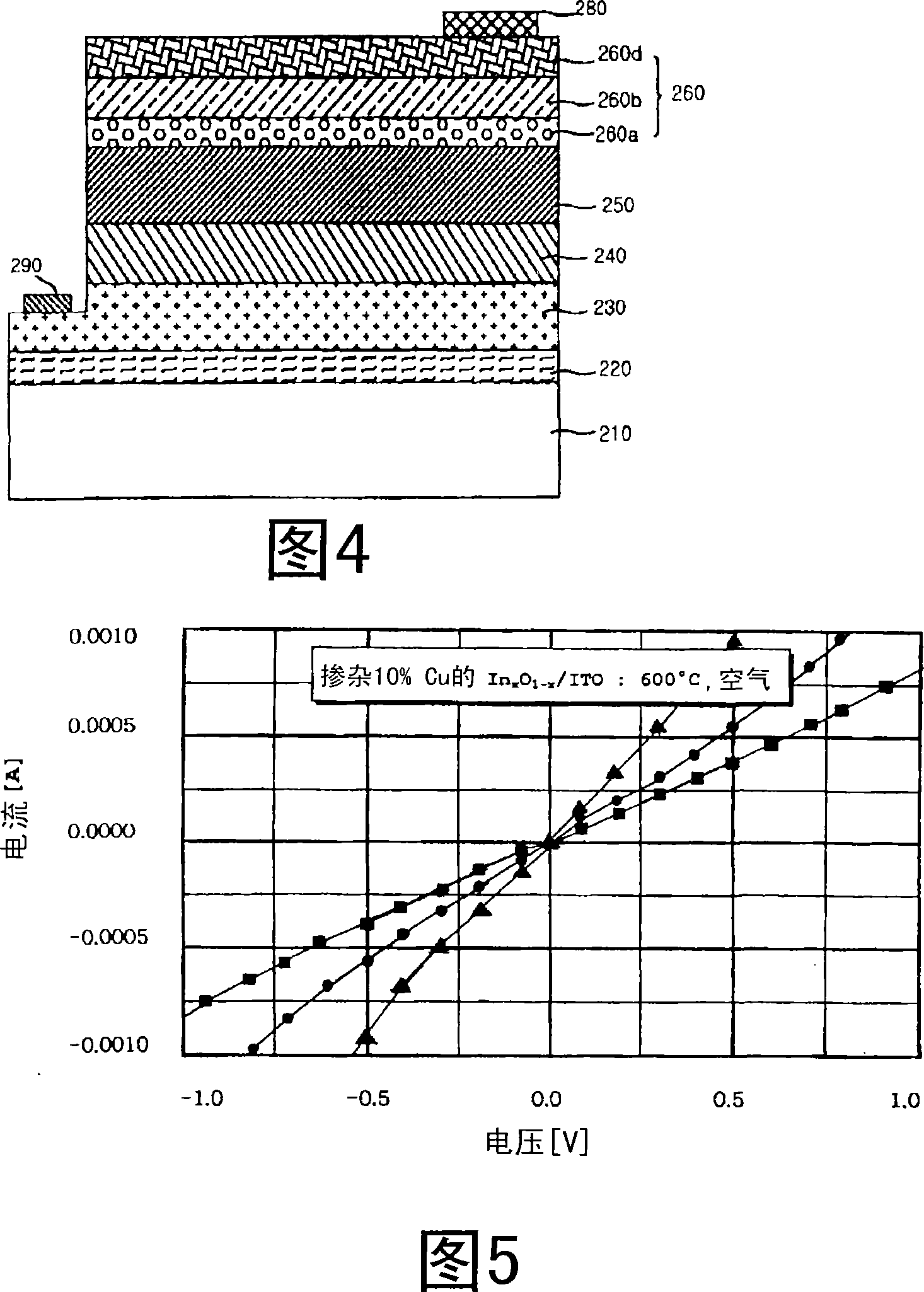

[0057] FIG. 1 shows a cross-sectional view of a top emission nitride-based light emitting device according to a first embodiment of the present invention.

[0058] Referring now to FIG. 1, a top emitting nitride-based light emitting device is formed by a structure comprising a substrate 110, a buffer layer 120, an n-type cladding layer 130, an active layer 140, a p -type cladding layer 150 , interface modification layer 160 and transparent conductive film layer 170 . Reference numerals 180 and 190 denote p-type electrode pads and n-type electrode pads, respectively.

[0059] In addition, the interface modification layer 160 and the transparent conductive film layer 170 stacked on the p-type cladding layer 150 correspond to a multi-ohmic contact layer, that is, a p-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com