Polaroid packaging and fixing device

A technology of fixing devices and polarizers, which is applied in the directions of packaging, transportation and packaging, and packaging of vulnerable items. It can solve problems that affect packaging work efficiency, yield, creases, and inconvenient operations, and improve customer input. Improve work efficiency, improve work efficiency, and improve packaging yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

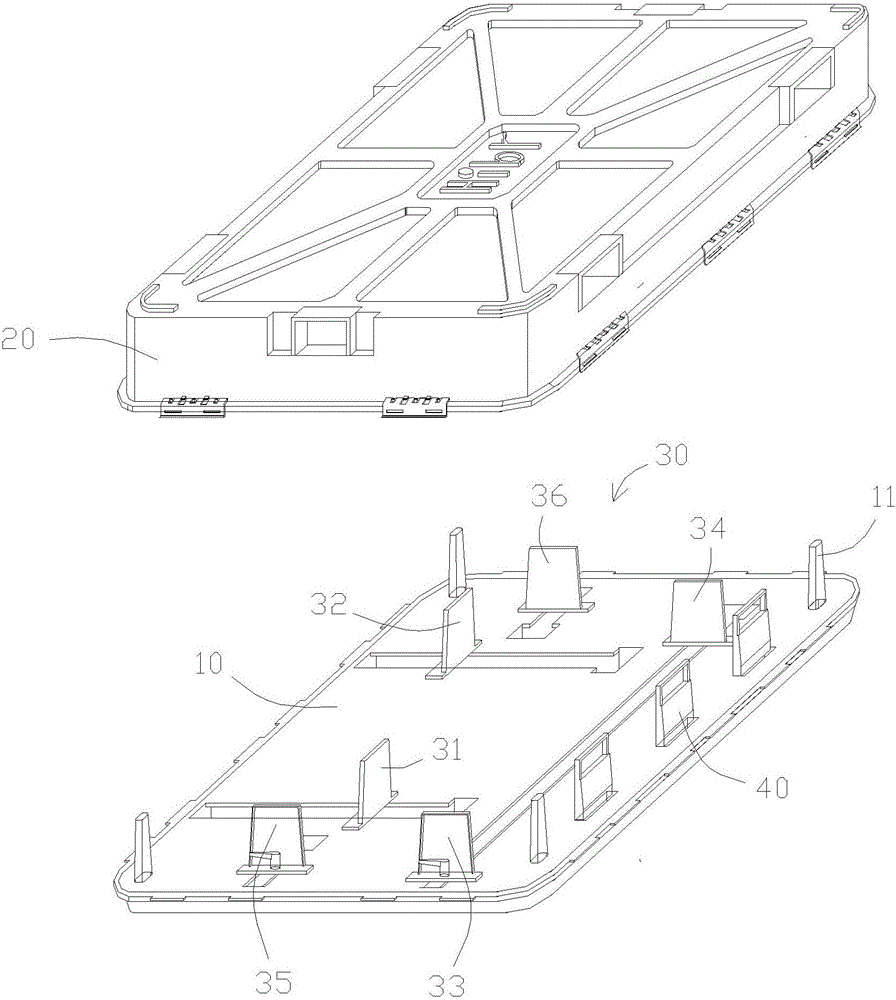

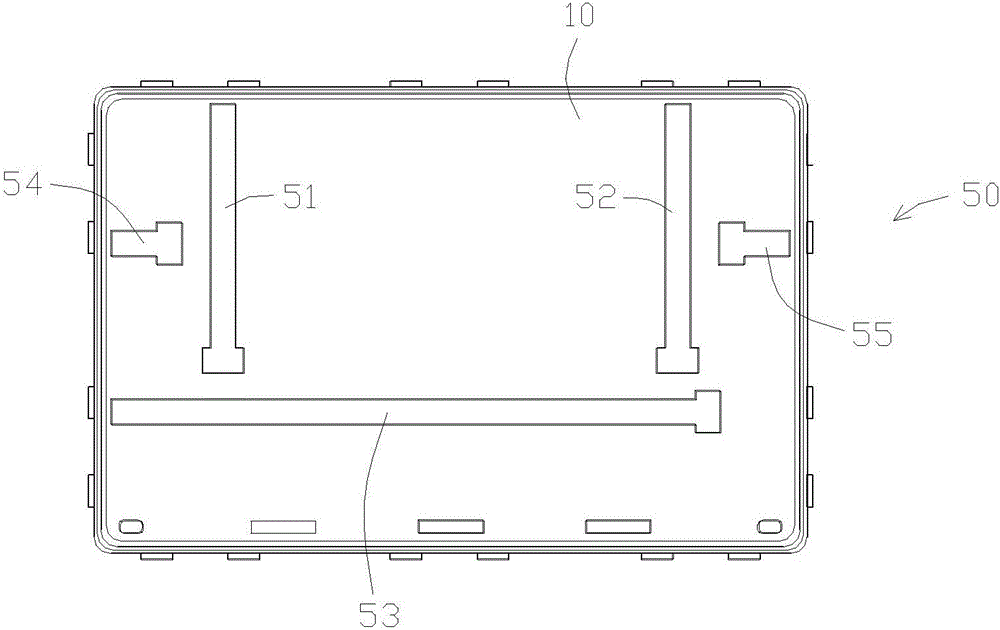

[0015] like figure 1 As shown, the polarizer packaging and fixing device includes a base 10 and an upper cover 20 for covering the base. The base and the upper cover are connected by a pluggable fixed stop post 11. In this embodiment, the pluggable fixed The blocking posts are arranged at the four corners of the base 10 . The base 10 is provided with a sliding baffle 30 and a fixed baffle 40 for fixing the polarizer, wherein the fixed baffle is arranged on one long side of the base and adopts a pluggable structure.

[0016] The sliding baffle 30 includes a first sliding baffle 31, a second sliding baffle 32, a third sliding baffle 33, a fourth sliding baffle 34, a fifth sliding baffle 35 and a sixth sliding baffle 36, so The first sliding baffle 31 and the second sliding baffle 32 are used to locate one long side of the polarizer, the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com