Packaging method for image sensor chip and packaging structure

An image sensor chip and packaging method technology, which is applied to electrical components, electrical solid state devices, circuits, etc., can solve the problems of detachment and defectiveness of the pads 12 of the rewiring layer 24, and achieves improving the packaging yield, avoiding detachment, and improving The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

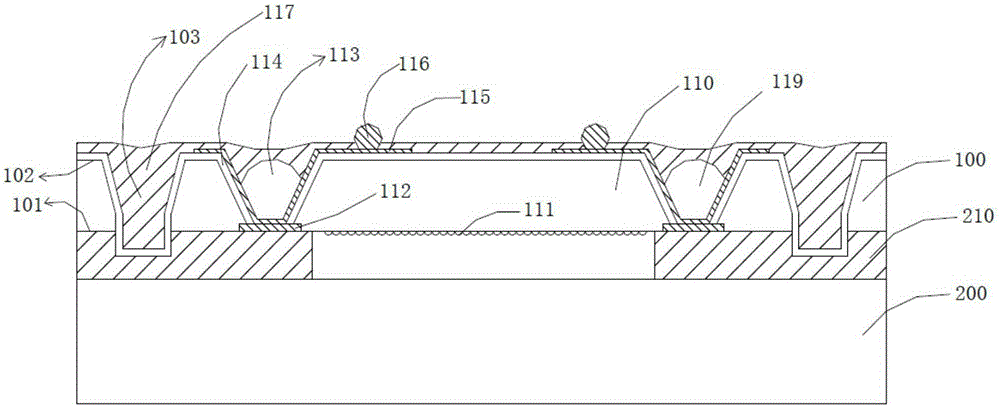

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

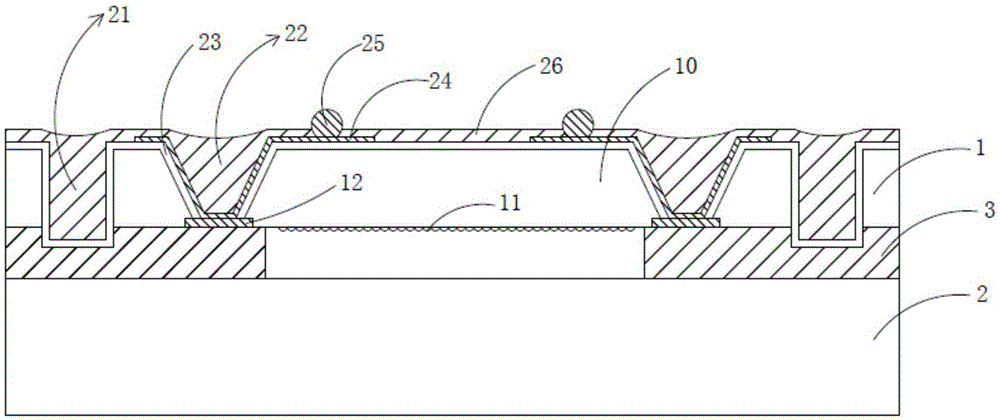

[0032] In the prior art, the solder resist ink fills the openings, so that the solder resist ink is in full contact with the rewiring layer, resulting in subsequent reflow soldering and reliability testing, the force formed by the shrinkage and expansion of the solder resist ink pulls the rewiring layer, which is easy to cause The redistribution layer is detached from the pad.

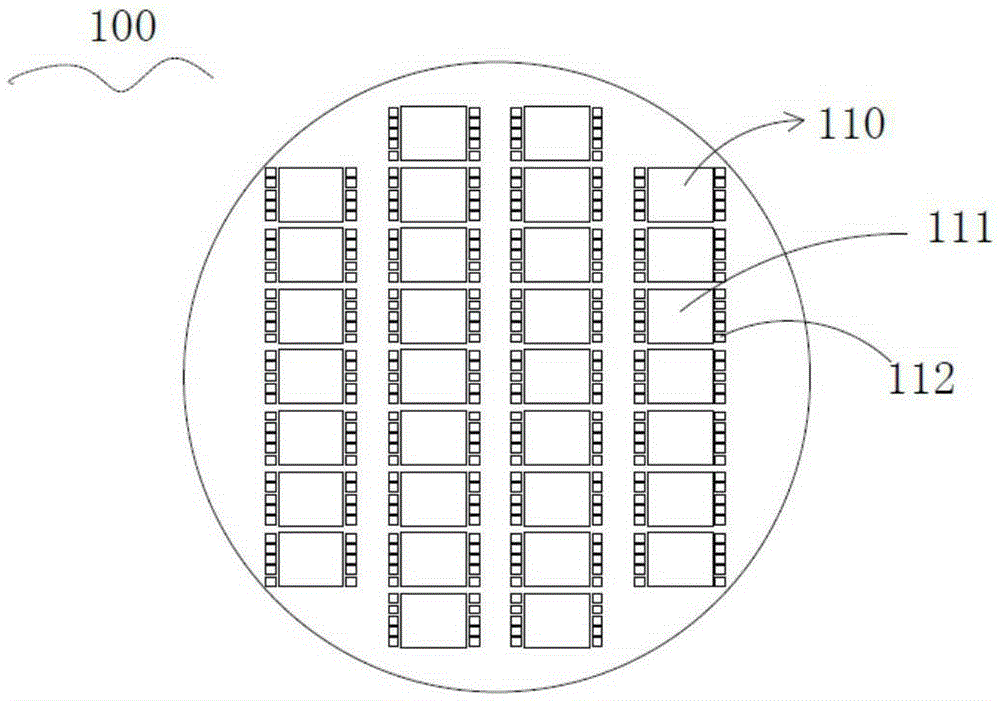

[0033] In order to solve the above problems, the present invention forms a cavity in the hole so that the solder resist ink does not contact the wiring layer at the bottom of the hole, which can effectively prevent the rewiring layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com