Calcium carbonate powder dispersing method

A calcium carbonate powder, dispersion technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc. To deal with problems such as slow efficiency, to avoid manual stirring, improve the speed of discharging, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

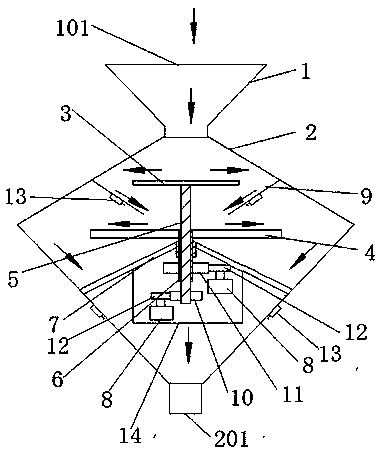

[0036] see figure 1 In the present invention, the dispersing device includes a feed plate 1, a casing 2 and a centrifugal device. The feed plate 1 is in the shape of a funnel with a large upper part and a smaller bottom. It is connected with the lower end of the material guide plate 1, the upper end of the material guide plate 1 is the material inlet 101, and the lower end of the shell 2 is the material outlet 201, and the centrifugal device is installed in the shell 2, and the centrifugal device includes a centrifugal disc I3, a centrifugal disc II4, a rotating shaft 5 and a shaft sleeve 6. The centrifugal disc I3 is located above the centrifugal disc II4. The centrifugal disc I3 is connected to the rotating shaft 5, and the centrifugal disc II4 is connected to the shaft sleeve 6. The rotating shaft 5 passes through the shaft sleeve 6 and enables the rotating shaft 5 and the shaft sleeve 6 to rotate independently of each other. The shaft sleeve 6 is fixed on the inner wall of...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, except that the transmission device is a belt transmission device, and the principle of the belt transmission device is basically the same as that of the gear transmission device. Drive pulley, then connect drive pulley on motor 8, be connected by belt between drive pulley and driven pulley.

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 2, except that the transmission device is a chain transmission device, that is, the driving sprocket is connected to the rotating shaft 5 and the shaft sleeve 6, and then the driven sprocket is set on the motor 8 , the driving sprocket and the driven sprocket are connected by a chain.

[0047] Wherein, the direction of the arrow in the accompanying drawing is the path direction of calcium carbonate powder and agglomeration in the dispersion process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com