Bending strength detection device for new material production

A bending strength and detection device technology, applied in the direction of using a stable bending force to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problems affecting the production progress, material splashing, and safety, so as to improve adaptability, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

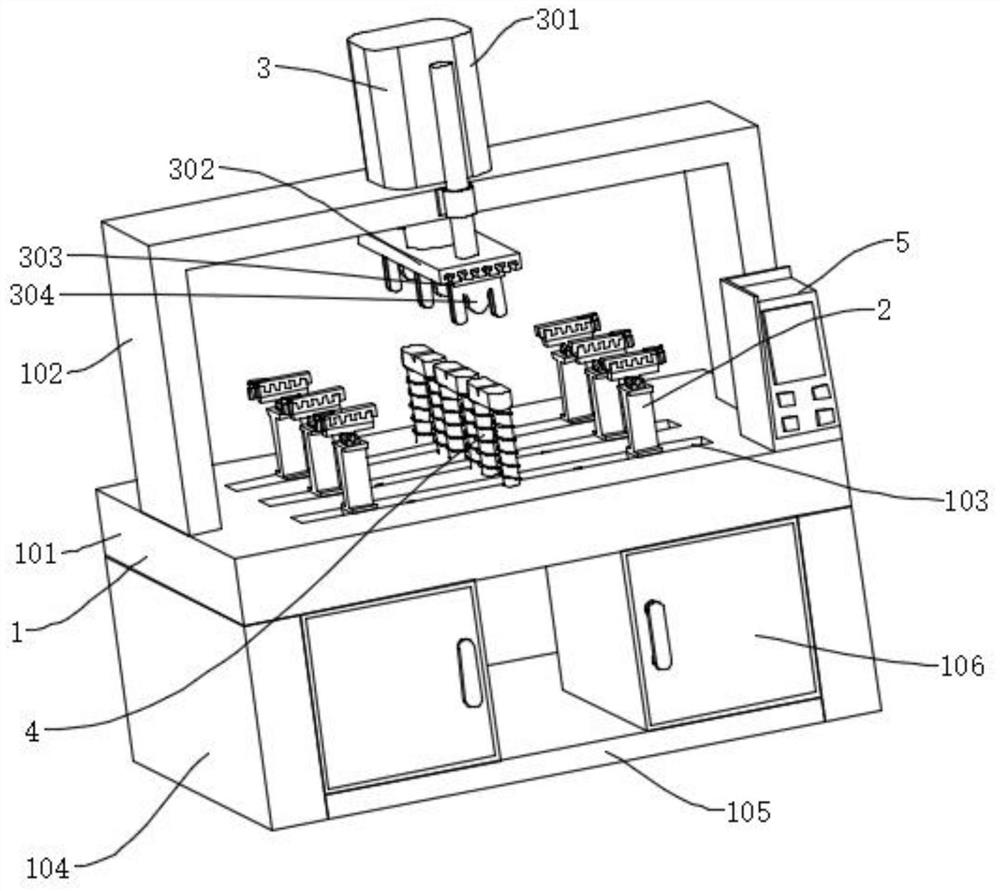

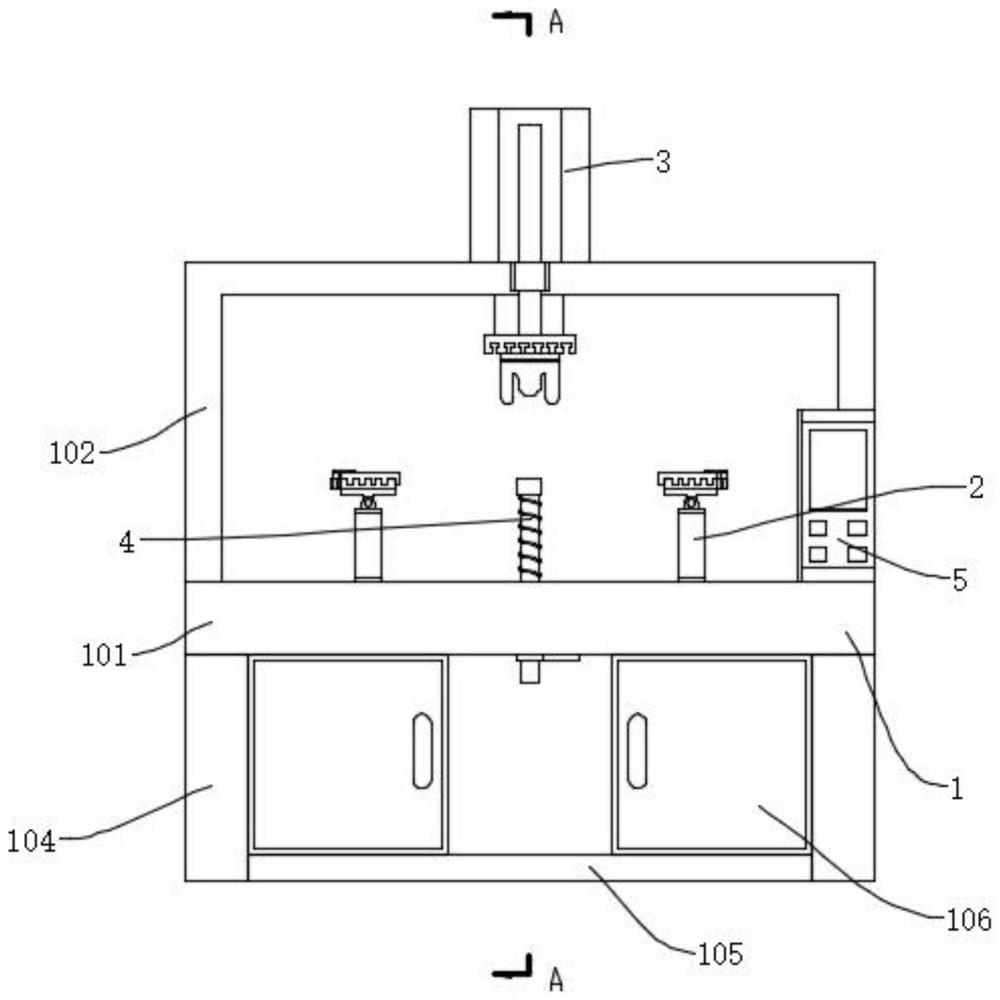

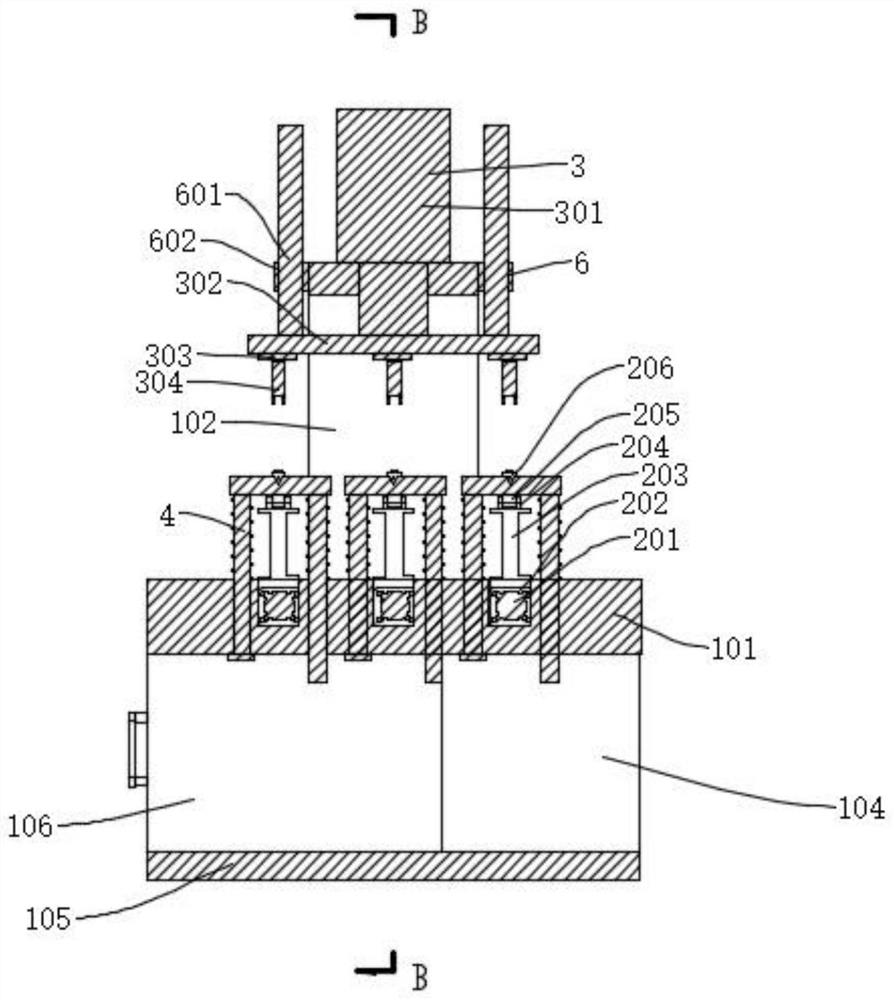

[0034] Such as Figure 1-7 As shown, a bending strength detection device for new material production includes a support mechanism 1 and a control panel 5. The support mechanism 1 is mainly composed of a working plate 101 and a frame 102, and also includes a discharge mechanism 2 and an extrusion mechanism 3. , Measuring mechanism 4, three chutes 103 are provided on the top of the supporting mechanism 1, and the three chutes 103 are arranged equidistantly before and after, each chute 103 is provided with a discharge mechanism 2 inside, and the discharge mechanism 2 includes a two-way cylinder 201 , the slider 202, the support seat 203, the discharge assembly 206, the two-way cylinder 201 is connected to the center of the inner side of the chute 103 by bolts, and the two output ends of the two-way cylinder 201 are connected with the slider 202 by bolts, and the slider 202 is slidably connected Inside the chute 103, the top of the slider 202 is connected with a support seat 203 b...

Embodiment 2

[0037] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the inside of the storage box 106 is connected with a vertically arranged second partition 1062 by screws, and the front end of the storage box 106 is connected with a door through a hinge, so that the setting can be effective. Increase the storage capacity of the storage box 106.

[0038] In the above structure, when in use, first adjust the distance between the two discharge assemblies 206 of the same group according to the length of the material. By starting the two-way cylinder 201, the two-way cylinder 201 drives the slider 202 to move, and the slider 202 drives the support seat 203 Move, the support base 203 drives the discharge assembly 206 to move through the rotating structure, so that the distance between the two discharge assemblies 206 is suitable, and then the material is placed in the V-shaped slot one on the discharge block 2061, and then the micro The cylinder 2063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com