Flexible package battery packaging process

A flexible packaging battery and packaging process technology, applied in the field of lithium-ion batteries, can solve problems such as defects and damage processing, and achieve the effects of improving the good rate, improving the defects, and improving the damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

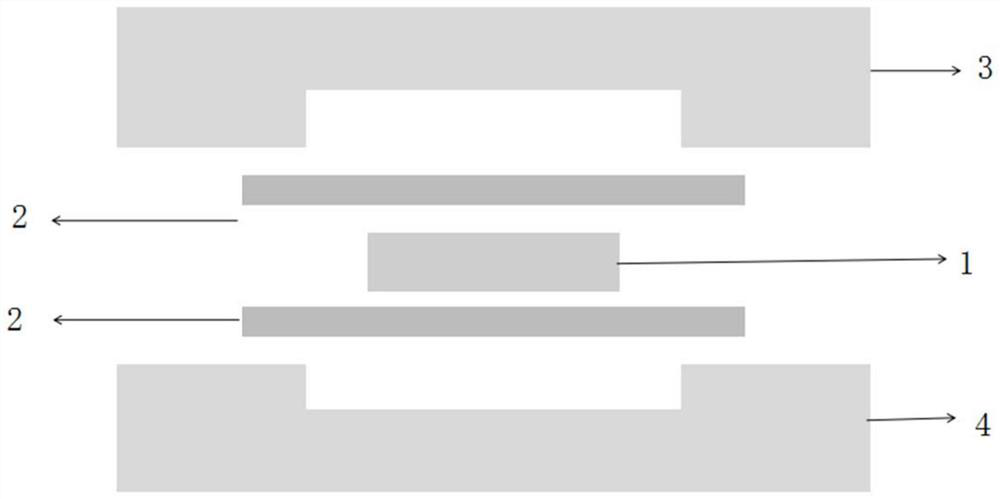

[0041] 1. Cut the coated pole piece into a specified size of 300mm*250mm with a die cutter, and cut the reserved part of the tab into the same size as the copper metal strip 1 after the lamination process;

[0042] 2. The metal strip 1 of a dense Cu-sodium formate coordination layer is obtained by copper surface treatment, and the pole piece is welded together to form the tab metal strip 1;

[0043] 3. Put the tab metal strip 1 and the aluminum-plastic film 2 into the tooling mold and fix them, use the high-frequency electromagnetic heating process to heat and seal the tab metal strip 1 and the aluminum-plastic film 2, and set a fixed pressure when heating and packaging, so that the pole The air between the ear metal strip 1 and the aluminum-plastic film 2 is exhausted, the temperature of the heating package is 170°C, and the given pressure value is 0.5mpa. The entire process takes 5.8 seconds to complete.

[0044] 4. The tab metal strip 1 and the aluminum-plastic film 2 are h...

Embodiment 2

[0047] 1. Cut the coated pole piece into a specified size of 300mm*250mm with a die cutter, and cut the reserved part of the tab into the same size as the copper metal strip 1 after the lamination process;

[0048] 2. The metal strip 1 of a dense Cu-sodium formate coordination layer is obtained by copper surface treatment, and the pole piece is welded together to form the tab metal strip 1;

[0049] 3. Put the tab metal strip 1 and the aluminum-plastic film 2 into the tooling mold and fix them, use the high-frequency electromagnetic heating process to heat and seal the tab metal strip 1 and the aluminum-plastic film 2, and set a fixed pressure when heating and packaging, so that the pole The air between the ear metal strip 1 and the aluminum-plastic film 2 is exhausted, the temperature of the heating package is 172°C, and the given pressure value is 0.5mpa. The entire process takes 5.0 seconds to complete. Use the high-frequency electromagnetic heating process to fully bond th...

Embodiment 3

[0053]1. Cut the coated pole piece into a specified size of 300mm*250mm with a die cutter, and cut the reserved part of the tab into the same size as the copper metal strip 1 after the lamination process;

[0054] 2. The metal strip 1 of a dense Cu-sodium formate coordination layer is obtained by copper surface treatment, and the pole piece is welded together to form the tab metal strip 1;

[0055] 3. Put the tab metal strip 1 and the aluminum-plastic film 2 into the tooling mold and fix them, use the high-frequency electromagnetic heating process to heat and seal the tab metal strip 1 and the aluminum-plastic film 2, and set a fixed pressure when heating and packaging to make the pole The air between the ear metal strip 1 and the aluminum-plastic film 2 is exhausted, the temperature of the heating package is 175°C, and the given pressure value is 0.5mpa. The entire process takes 4 seconds to complete. 4. The tab metal strip 1 and the aluminum-plastic film 2 are hot-melted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com