Rotating equipment and using method

A technology of rotating equipment and rotating devices, applied to chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve the problems of poor control of distribution and mixing, large mass of rotating rotors, and high energy consumption of motors, etc. problems, to achieve the effect of high good rate, high production efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

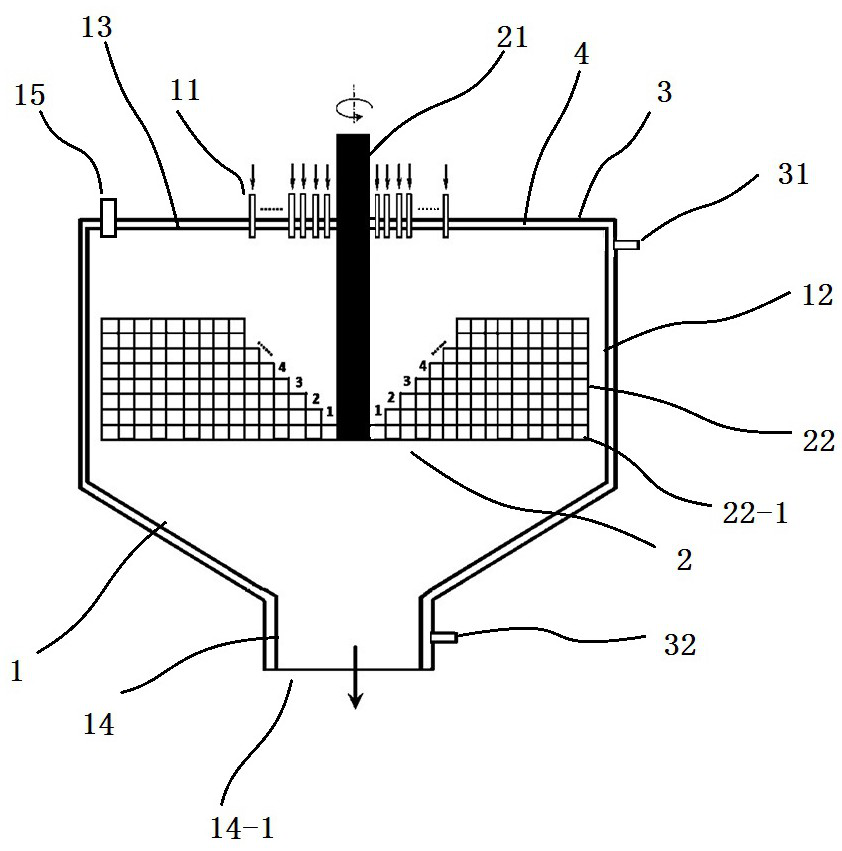

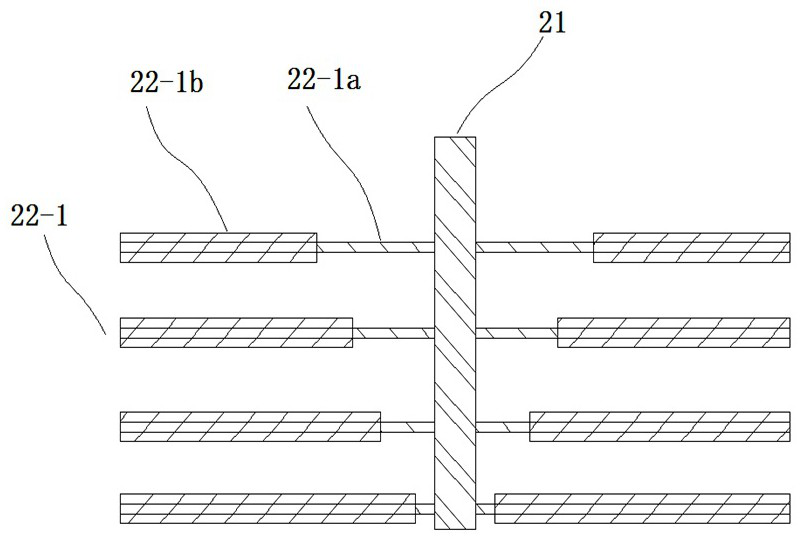

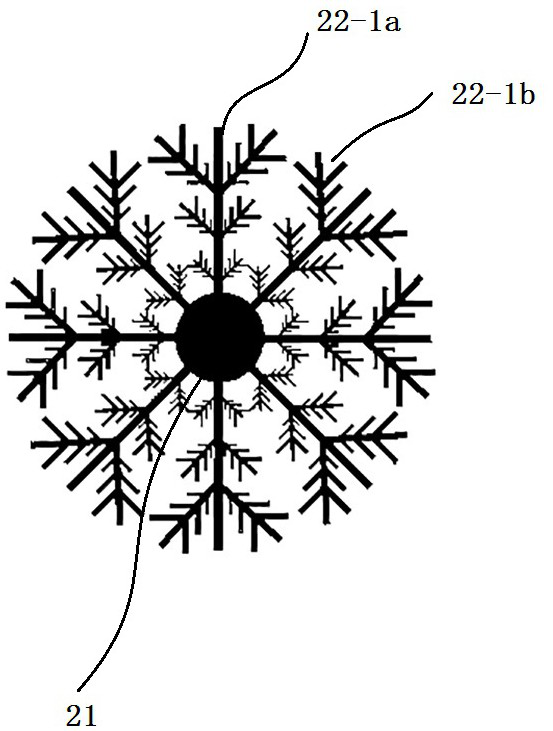

[0036] refer to Figure 1 to Figure 3 , a kind of rotating equipment, comprises reaction box shell 1, the rotating device 2 that is placed in reaction box shell 1, the motor that provides kinetic energy to rotating device 2 and the vacuum pump that is connected with reaction box shell, and described rotating device 2 includes vertically arranged The rotating shaft 21 and the dispersing component 22 installed on the rotating shaft 21 to form a fractal geometric structure. The dispersing assembly 22 includes four dispersing layers 22-1 installed on the rotating shaft 21, and each dispersing layer includes eight radially arranged support rods 22-1a and dispersing elements 22-1b on the support rods . A protruding portion is formed at one end of each dispersing element 22-1b close to the rotating shaft 21, and the protruding portion on the upper dispersing layer is farther away from the rotating shaft 21 than the protruding portion on the lower dispersing layer. The rotating devi...

Embodiment 2

[0042] like Figure 4 The difference between this embodiment shown and Embodiment 1 is that the dispersing element 22-1b of this embodiment is a brush piece of flexible polymer material, and its effect is the same as that of the above embodiment. Brush blades are more suitable for stirring harder materials.

Embodiment 3

[0044] A method for using a rotating device, comprising the following steps:

[0045] S1, start the motor connected to the rotating shaft 21, so that the rotating device 2 is idling; start the vacuum pump connected to the vacuum pump interface 15 to pump and decompress the inside of the reaction box shell 1, so that the inside of the reaction box shell reaches the vacuum requirement during the reaction ;

[0046] S2. Inject high-temperature or low-temperature circulating liquid into the thermal interlayer 4 through the jacket shell circulating liquid inlet 32 and flow out through the jacket shell circulating liquid outlet 31, and continue to circulate so that the temperature in the reaction tank shell 1 reaches the standard;

[0047] S3. Finally, different materials are poured into the reaction box shell 1 through each material inlet 11, so that each material falls into the active area where the protrusion of a dispersion element 22-1b in the reaction box shell is located, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com