Plasma processing apparatus

A plasma and processing device technology, which is applied in the field of plasma processing devices, can solve problems such as defects, damage to ceramic cover plates, and influence on the good rate of the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

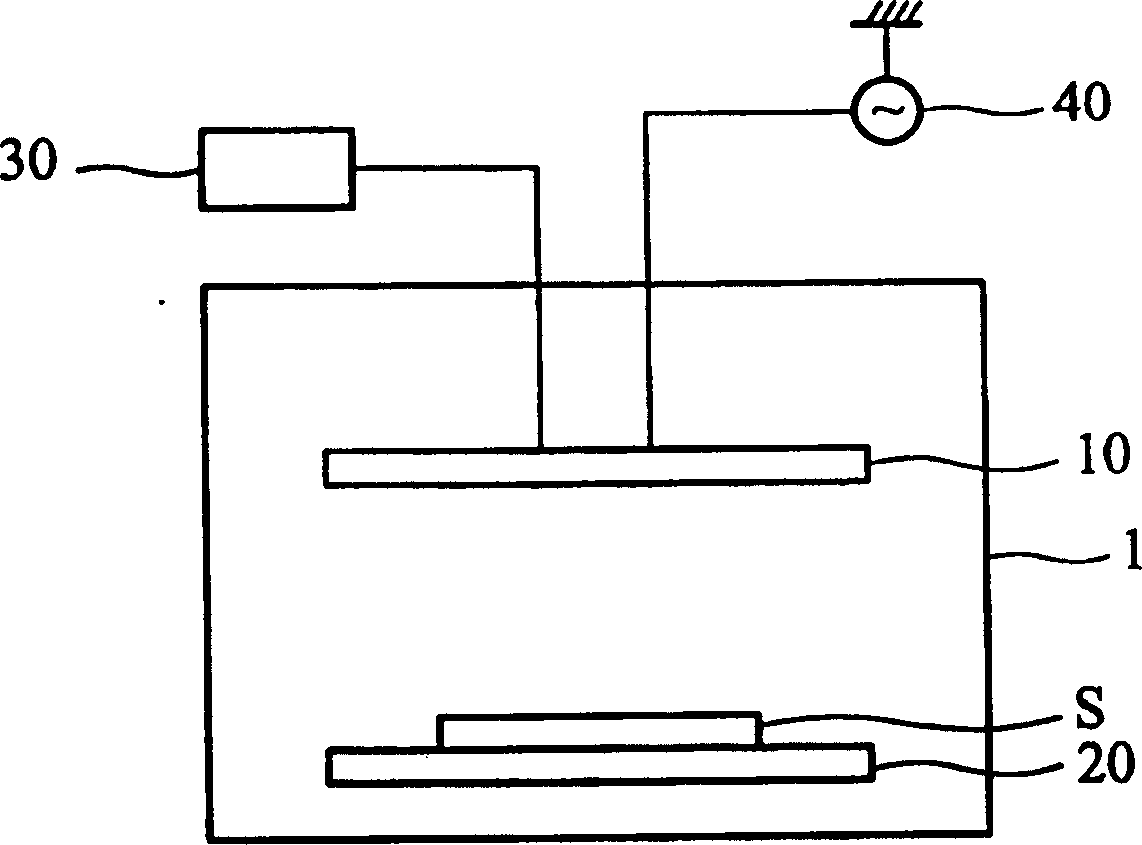

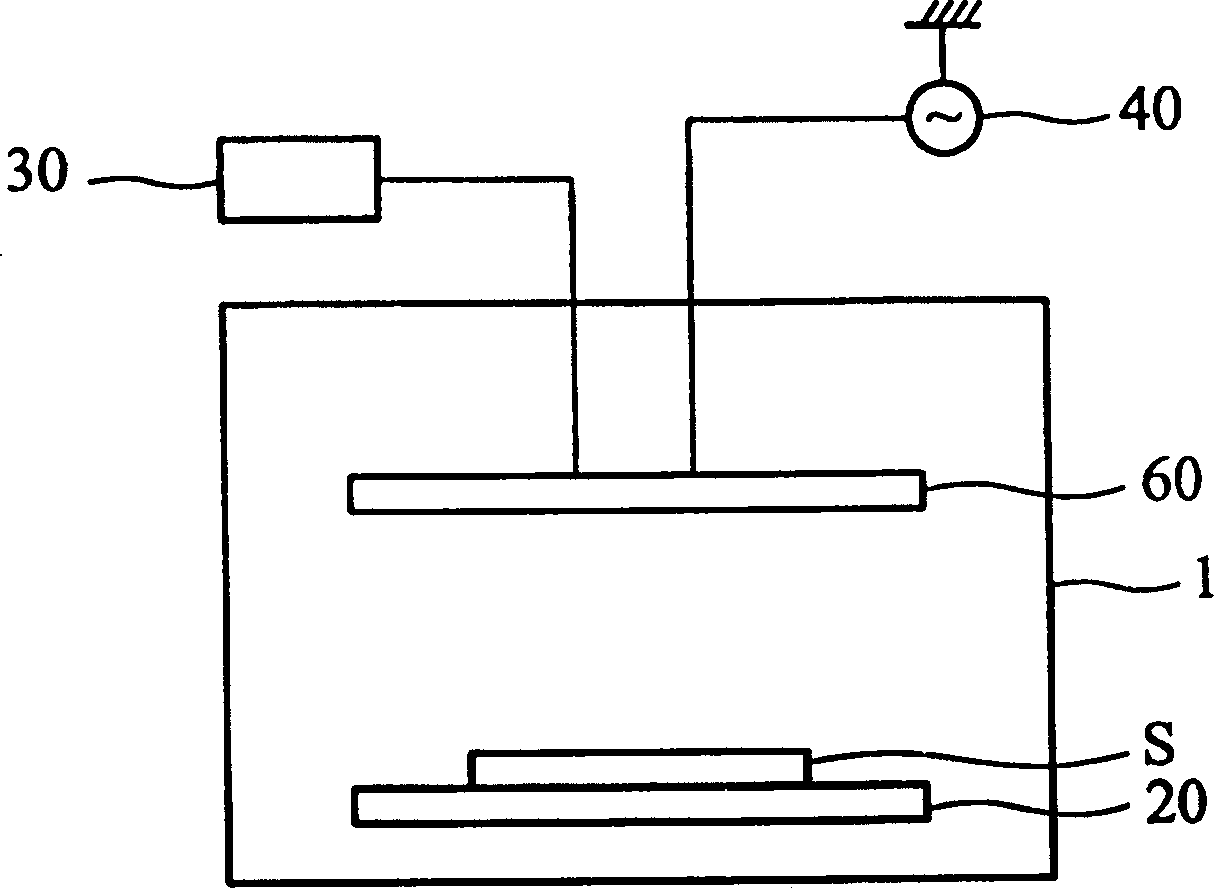

[0024] image 3 A schematic diagram showing a plasma processing apparatus according to a preferred embodiment of the present invention. The plasma processing device includes a processing chamber 1 , a gas supply system 30 and a power source 40 . Inside the processing chamber 1 , there is an upper electrode plate 60 and a lower electrode plate 20 . A substrate S to be subjected to plasma treatment can be placed on the lower electrode plate 20, such as a semiconductor substrate used in the semiconductor manufacturing process, or a glass substrate or transparent plastic substrate used in the TFT-LCD manufacturing process. The gas supply system 30 can supply gas into the processing chamber 1 . The power source 40 may be a radio frequency (RF) for applying a voltage difference between the upper and lower electrode plates 60 and 20 to convert the gas in the processing chamber 1 into plasma.

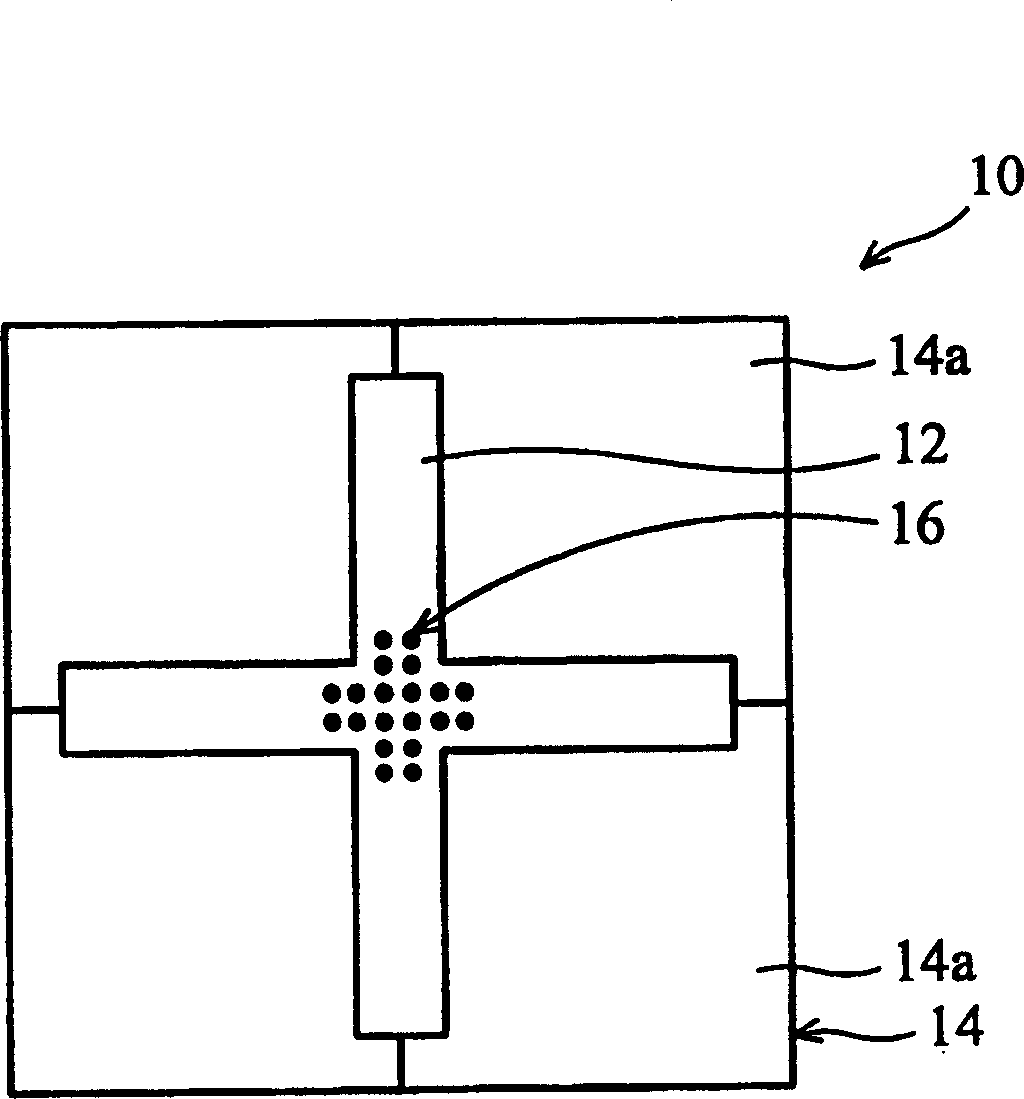

[0025] A feature of the present invention is the improvement of the upper electrode plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com