Forming method for uniformly distributing fluorescer on light-emitting diode

A light-emitting diode, uniform distribution technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of different quality of soft glue, waste of human resources, uneven soft glue, etc., achieve uniform brightness distribution, shorten manufacturing time, Guaranteed quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above and other features and advantages of the present invention will be described in detail below with reference to the accompanying drawings.

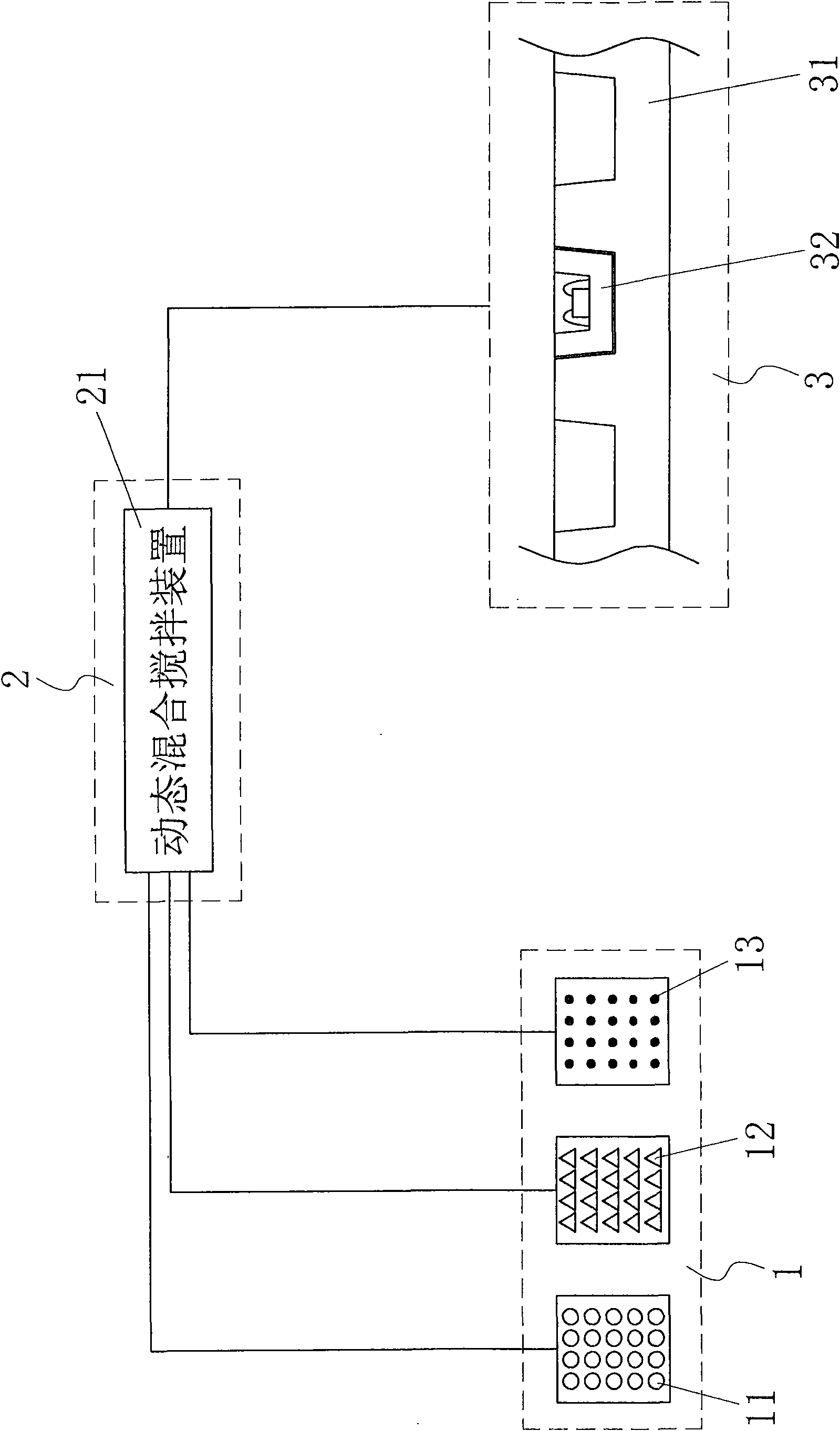

[0024] see figure 2 As shown, the main purpose of the present invention provides a molding method for uniformly distributing fluorescent agent in light-emitting diodes, which includes the following steps:

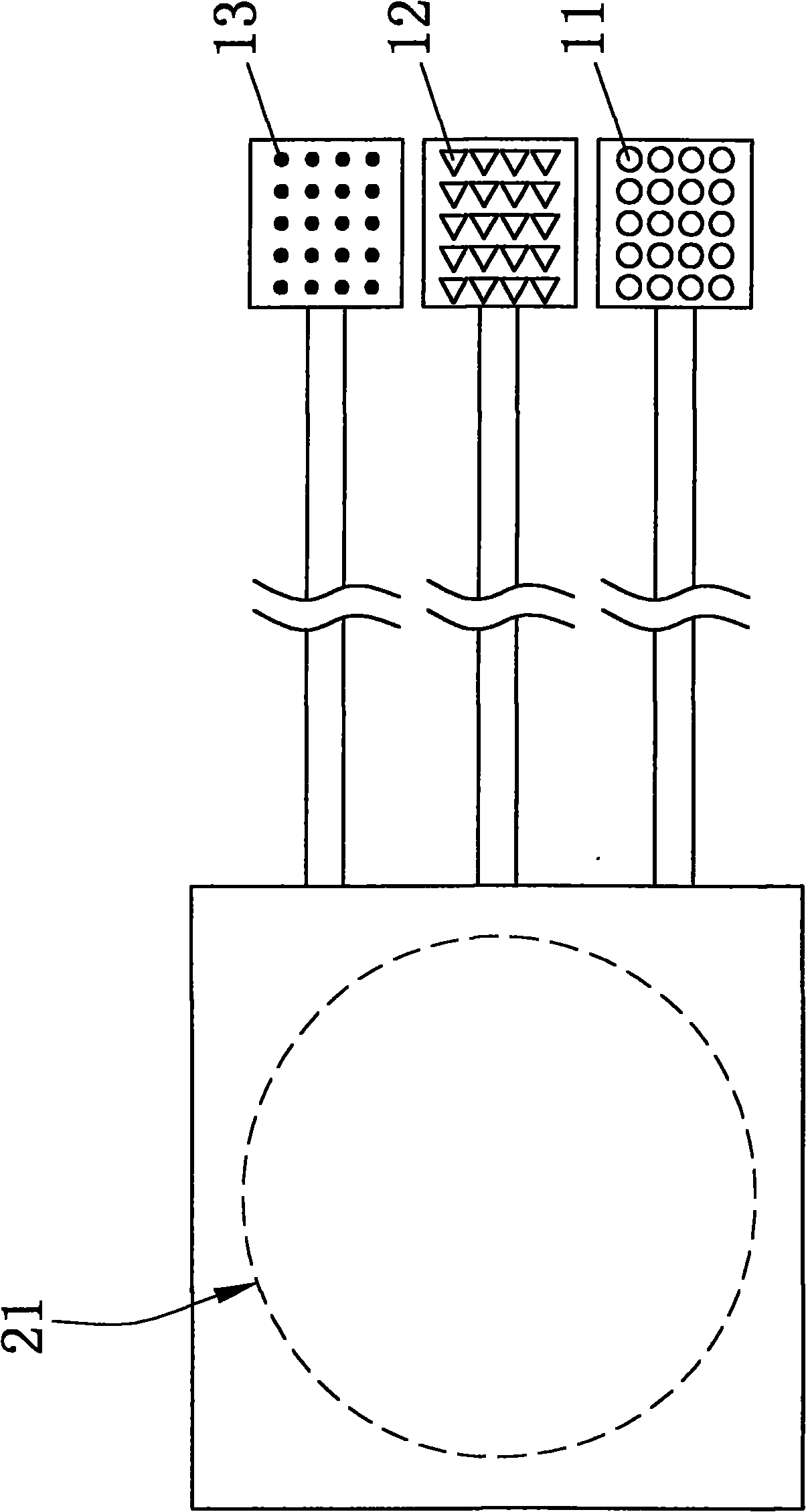

[0025] Material preparation step 1: In the material preparation step 1, the first liquid glue 11, the second liquid glue 12, and the fluorescent material liquid glue 13 are prepared, wherein the first liquid glue 11 is made of silicone resin (silicon resin) material, and the second liquid glue The second liquid glue 12 is a liquid glue made of silicone rubber. Through the material preparation step 1, the first liquid glue 11, the second liquid glue 12, and the fluorescent (fluorescent) material liquid glue 13 are respectively prepared, and they can be separated according to requirements. adjusting the concentration ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com