Printed circuit board

A printed circuit board and pad technology, which is applied in the direction of printed circuit components and electrical components to assemble printed circuits, can solve problems such as short circuit of adjacent pads, overflow, and increased defective rate of printed circuit boards, and achieve good improvement. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

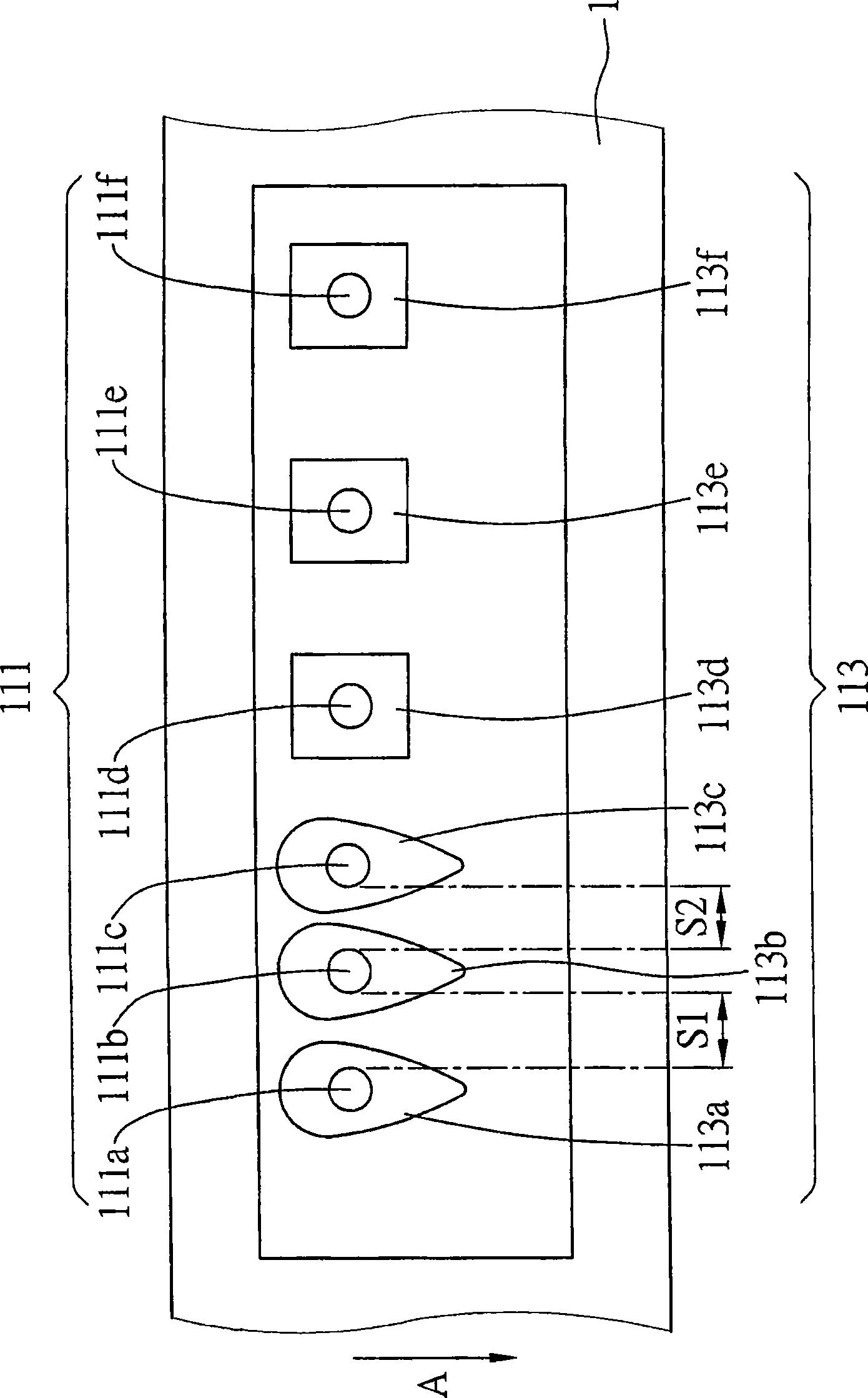

[0019] see figure 1 , showing a schematic diagram of the layout structure of the printed circuit board of the present invention. As shown in the figure, the printed circuit board 1 is provided with at least one soldering area 11 for corresponding connection with a through-hole component (Through-Hole Component; THC) having a plurality of pins (pins), and each of the pins There are at least two pins whose spacing is less than a specific distance, and the soldering area 11 has a plurality of through holes 111 that pass through the printed circuit board 1 and provide for correspondingly connecting each of the pins, and are arranged on the printed circuit board 1. 1 surface and disposed around the through hole 111 for soldering a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com