Liquid crystal display device and manufacturing method thereof

A liquid crystal display device and liquid crystal layer technology, applied in transistors, static indicators, optics, etc., can solve problems such as crosstalk, decrease in pixel aperture ratio, panel scrapping, etc., and achieve the effect of increasing the aperture ratio and improving the good rate of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

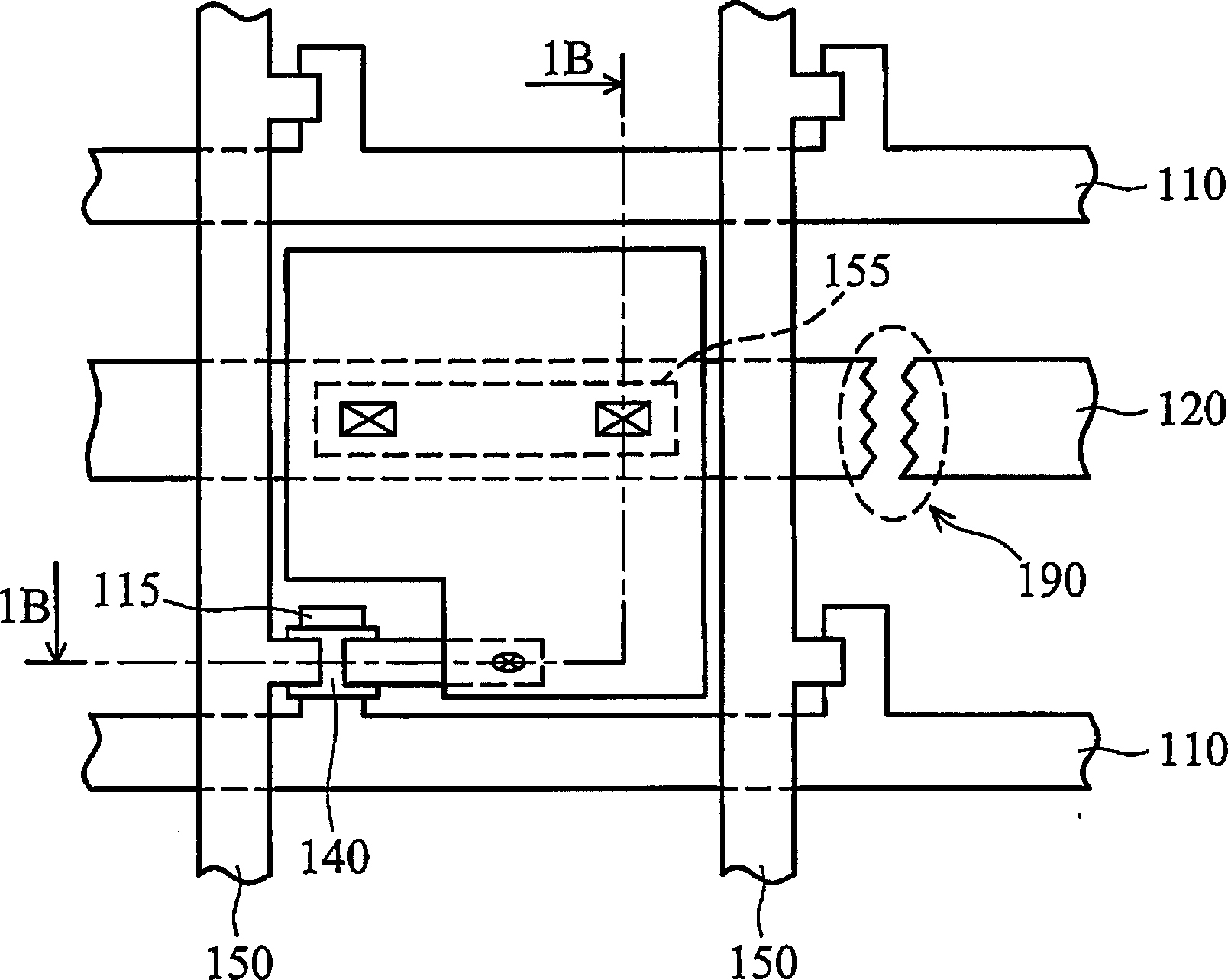

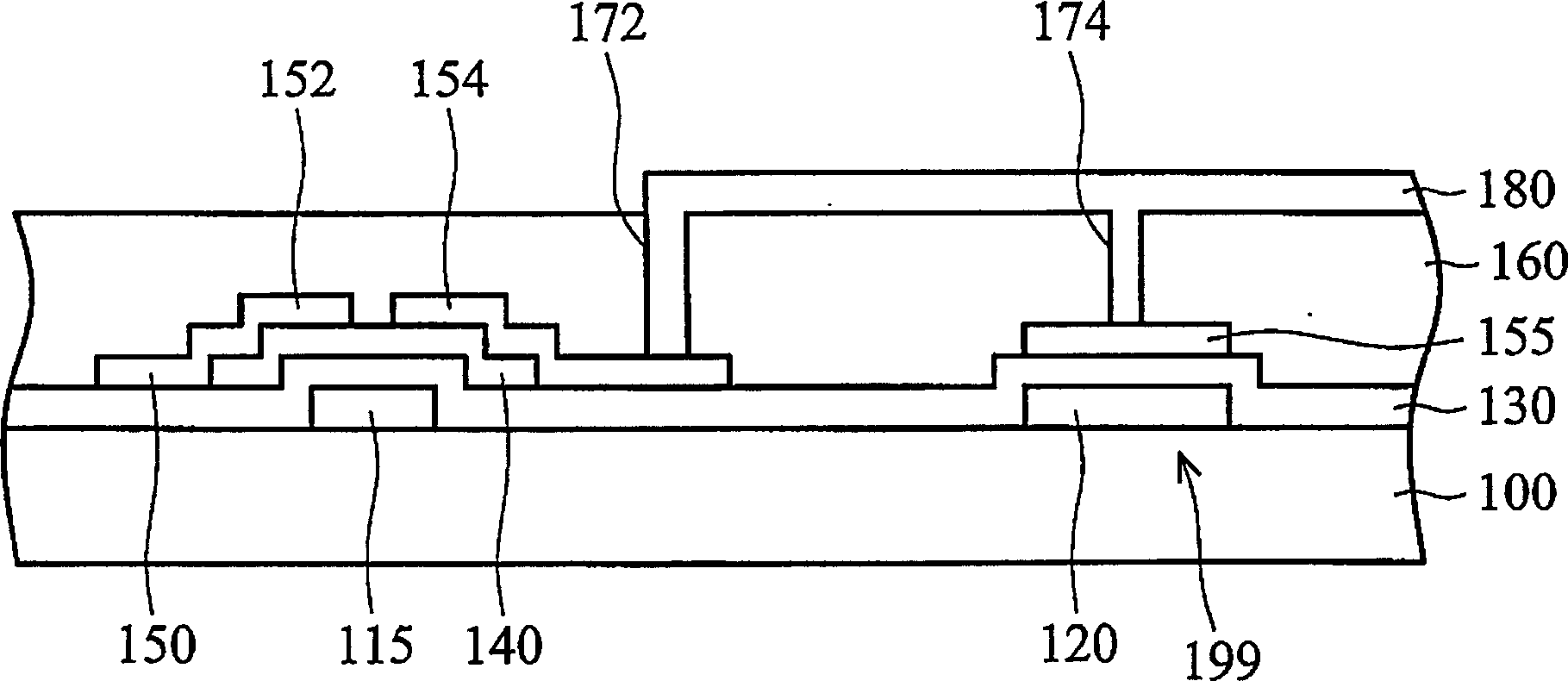

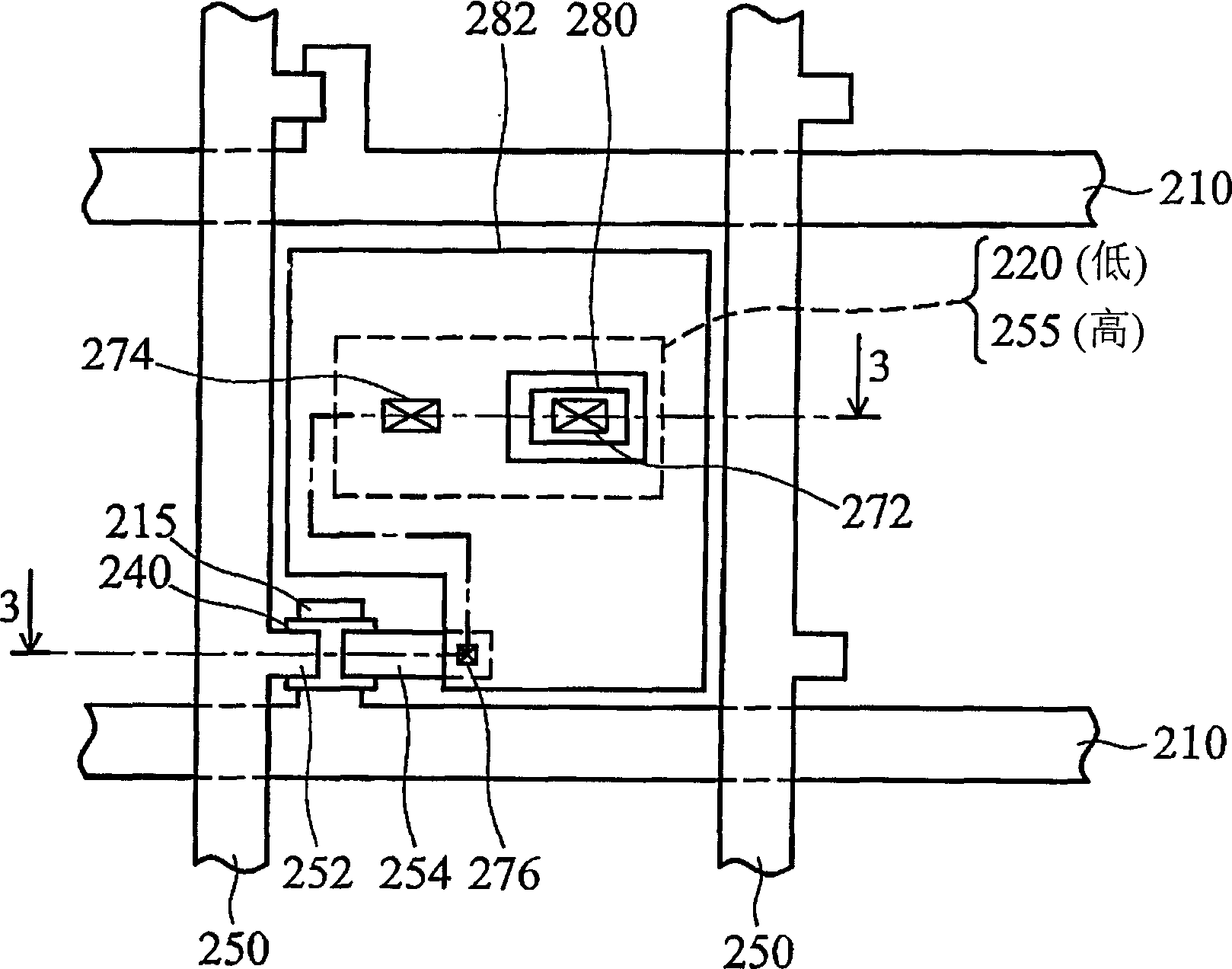

[0033] figure 2 is a partial plan view showing a liquid crystal display device according to a first embodiment of the present invention, and image 3 is along figure 2 The sectional view of line 3-3 in is used to illustrate the process of the first embodiment. It should be particularly noted here that although the following illustrations only show one pixel area, in fact the liquid crystal display device of the present invention may include many pixel areas.

[0034] see figure 2 and 3 , first provide an insulating substrate 200 (hereinafter referred to as a lower substrate) such as glass or quartz. A gate line 210 extending laterally and a discrete first metal layer 220 are formed on the lower substrate 200 , the gate line has a gate 215 . Wherein, the gate line 210 and the first metal layer 220 may be formed by the same deposition step, and the material thereof is, for example, Al, Cr, Mo or their alloys and other conductive materials.

[0035] Afterwards, a dielect...

no. 2 example

[0061] Figure 7 is a partial plan view showing a liquid crystal display device according to a second embodiment of the present invention, and Figure 8 is along Figure 7 The cross-sectional view of line 8-8 in the figure is used to illustrate the process of the second embodiment. It should be noted here that although the following diagrams only show one pixel area, in fact the liquid crystal display device of the present invention may include many pixel areas.

[0062] see Figure 7 and 8 , first provide an insulating substrate 700 (hereinafter referred to as a lower substrate) such as glass or quartz. A gate line 710 extending laterally and a separate layer of metal layer 720 are formed on the lower substrate 700 , the gate line has a gate 715 . Wherein, the gate line 710 and the metal layer 720 may be formed by the same deposition step, and the material thereof is, for example, a conductive material such as Al, Cr, Mo or an alloy thereof.

[0063] After that, a diele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com