Caster with brake structure

A technology of casters and runners, which is applied in the direction of casters, wheels, vehicle parts, etc., and can solve the problems of casters losing their positioning, low friction of anti-sliding blocks, and shaking of positioning blocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

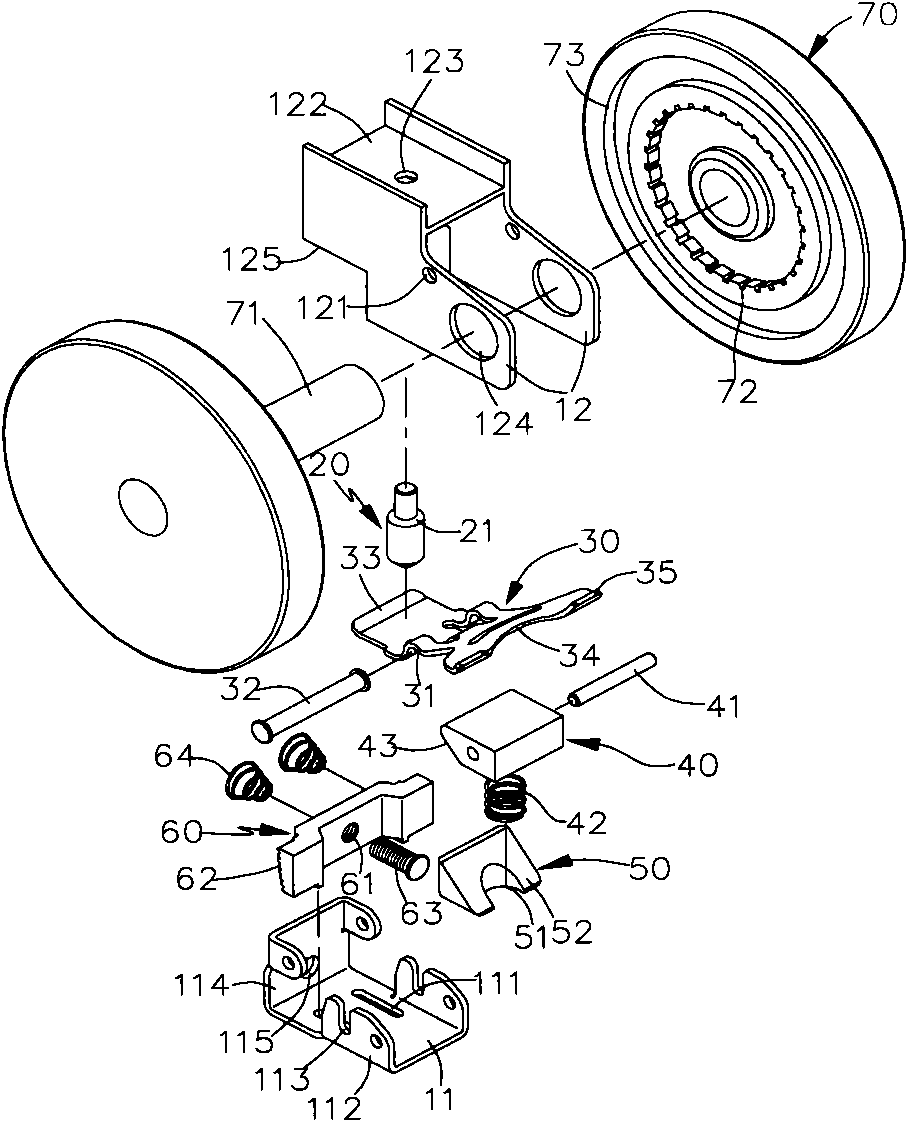

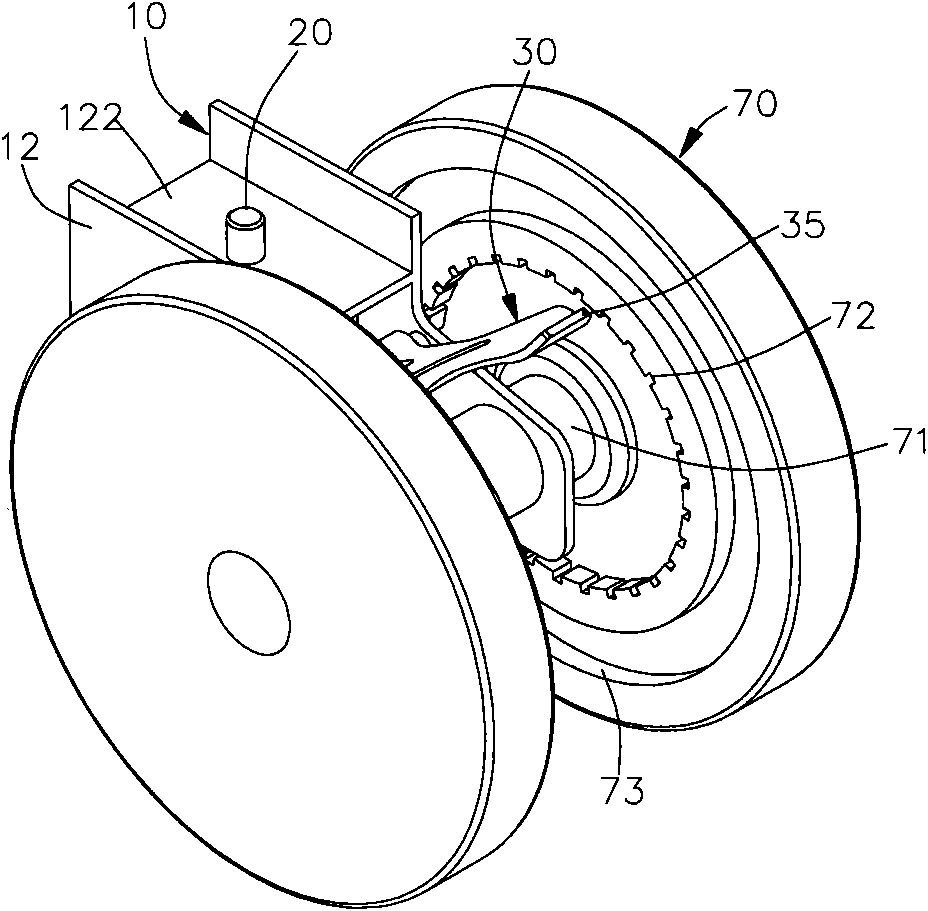

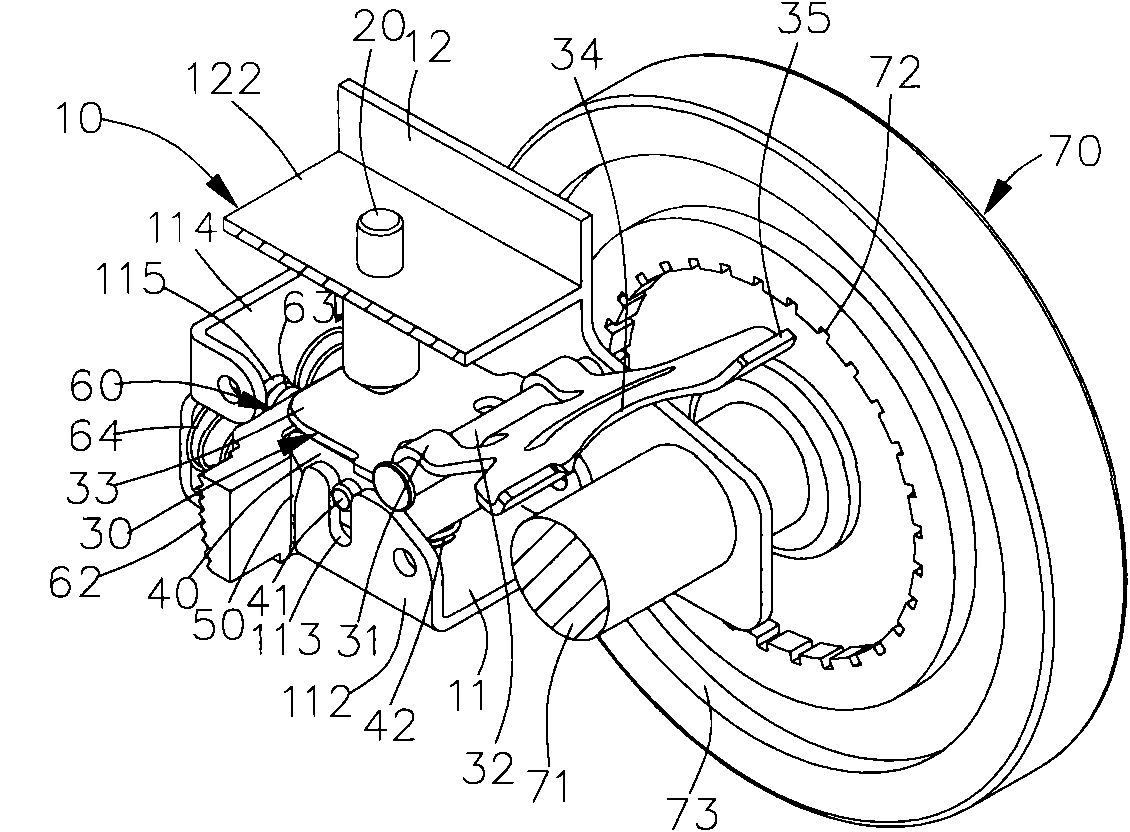

[0041] The caster with brake structure according to the present invention, the embodiment is such as Figure 1 to Figure 5 shown, including:

[0042] A frame body 10 has a bottom frame 11 and two side frames 12. The bottom frame 11 has two rails 111. The opposite sides of the bottom frame 11 have a connecting plate 112 extending vertically. Each connecting plate 112 has a vertical To the extended slit 113, the other side of the bottom frame 11 has a vertically extending baffle plate 114, the baffle plate 114 has a perforation 115, each side frame 12 is located at each connecting plate 112 of the bottom frame 11, each side frame 12 It has a pivot hole 121, a shaft hole 124 and a gap 125, and the two side frames 12 are connected by a top plate 122, the top plate 122 is located above the bottom frame 11 and has a through hole 123;

[0043] An operating piece 20 is columnar, and the middle section of the operating piece 20 has a shoulder 21, so that when one end of the operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com