Method for manufacturing metallic-crystal enameled brick

A technology of metal crystallization and manufacturing methods, which is applied in the field of ceramic tile manufacturing, can solve problems such as difficult control of crystal size and color, single effect of metal crystallized glazed tiles, unnatural patterns and colors, etc., to achieve controllable crystallization effect, cost reduction, The effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

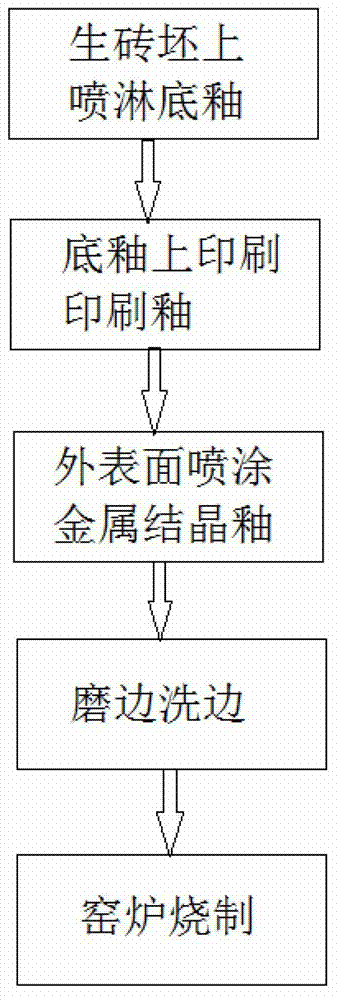

[0017] like figure 1 As shown, the base glaze is first sprayed on the raw brick to form the base glaze 1; the printing glaze 2 is printed on the base glaze 1; the metal crystal glaze 3 is sprayed on the outer surface printed with the printing glaze 2, and after grinding and edging , and then fired in a kiln once.

[0018] The composition of metal crystal glaze 3 in the present embodiment is: SiO 2 : 40%; Al 2 o 3 : 5%; Fe 2 o 3 : 15%; P 2 o 5 : 18%; MgO: 15%; K 2 O: 1%; Na 2 O: 1%; CO 2 : 5%.

[0019] It should be noted that the above CO 2 Commonly known as burn-out in the industry, it refers to the gas loss generated during the pre-treatment process of the metal crystal glaze. Since this treatment process is not involved in the present invention, it will not be described in detail, and the subsequent embodiments are also the same.

[0020] The printing glaze 2 in this embodiment is a powder containing metal elements such as metal magnesium, aluminum, titanium (occ...

Embodiment 2

[0023] like figure 1 As shown, the base glaze is first sprayed on the raw brick to form the base glaze 1; the printing glaze 2 is printed on the base glaze 1; the metal crystal glaze 3 is sprayed on the outer surface printed with the printing glaze 2, and after grinding and edging , and then fired in a kiln once.

[0024] The composition of metal crystal glaze 3 in the present embodiment is: SiO 2 : 35%; Al 2 o 3 : 3%; Fe 2 o 3 : 14.5%; P 2 o 5 : 14%; CaO: 5%; MgO: 14.5%; K 2 O: 4%; CO 2 : 10%.

[0025] The printing glaze 2 in this embodiment is a powder containing metal elements such as metal magnesium, aluminum, titanium (accounting for 85% of the proportion), and its fineness is 30 microns, which is printed on the bottom glaze 1 by a roller, The bottom glaze 1 is a mixture containing calcium, magnesium and silicon and aluminum (accounting for 40% by weight). Among the components of the printing glaze 2 and the bottom glaze 1, the other 15% and 60% are common cera...

Embodiment 3

[0028] like figure 1 As shown, the base glaze is first sprayed on the raw brick to form the base glaze 1; the printing glaze 2 is printed on the base glaze 1; the metal crystal glaze 3 is sprayed on the outer surface printed with the printing glaze 2, and after grinding and washing , and then fired in a kiln once.

[0029] The composition of metal crystal glaze 3 in the present embodiment is: SiO 2 : 39%; Al 2 o 3 : 4%; Fe 2 o 3 : 13%; P 2 o 5 : 12%; CaO: 4.5%; MgO: 14.5%; Na 2 O: 4%; CO 2 :9%.

[0030] The printing glaze 2 in the present embodiment contains Na 2 O, K 2 The powder of alkali metal elements such as O (accounting for 75% of the proportion) has a fineness of 20 microns, and it is printed on the bottom glaze 1 by roller printing. 60%) of the mixture. Among the components of the printing glaze 2 and the bottom glaze 1, the other 25% and 40% are common ceramic tile ingredients, such as base powder, etc., which will not be repeated here.

[0031] Edge gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com