Lamination device

A technology of pressing device and pressing parts, applied in the field of pressing device, can solve the problems of pressing error, product reliability decline, insufficient fitting, etc., so as to improve the accuracy, overcome the manufacturing tolerance, and eliminate the adverse effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A pressing device according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same component symbols.

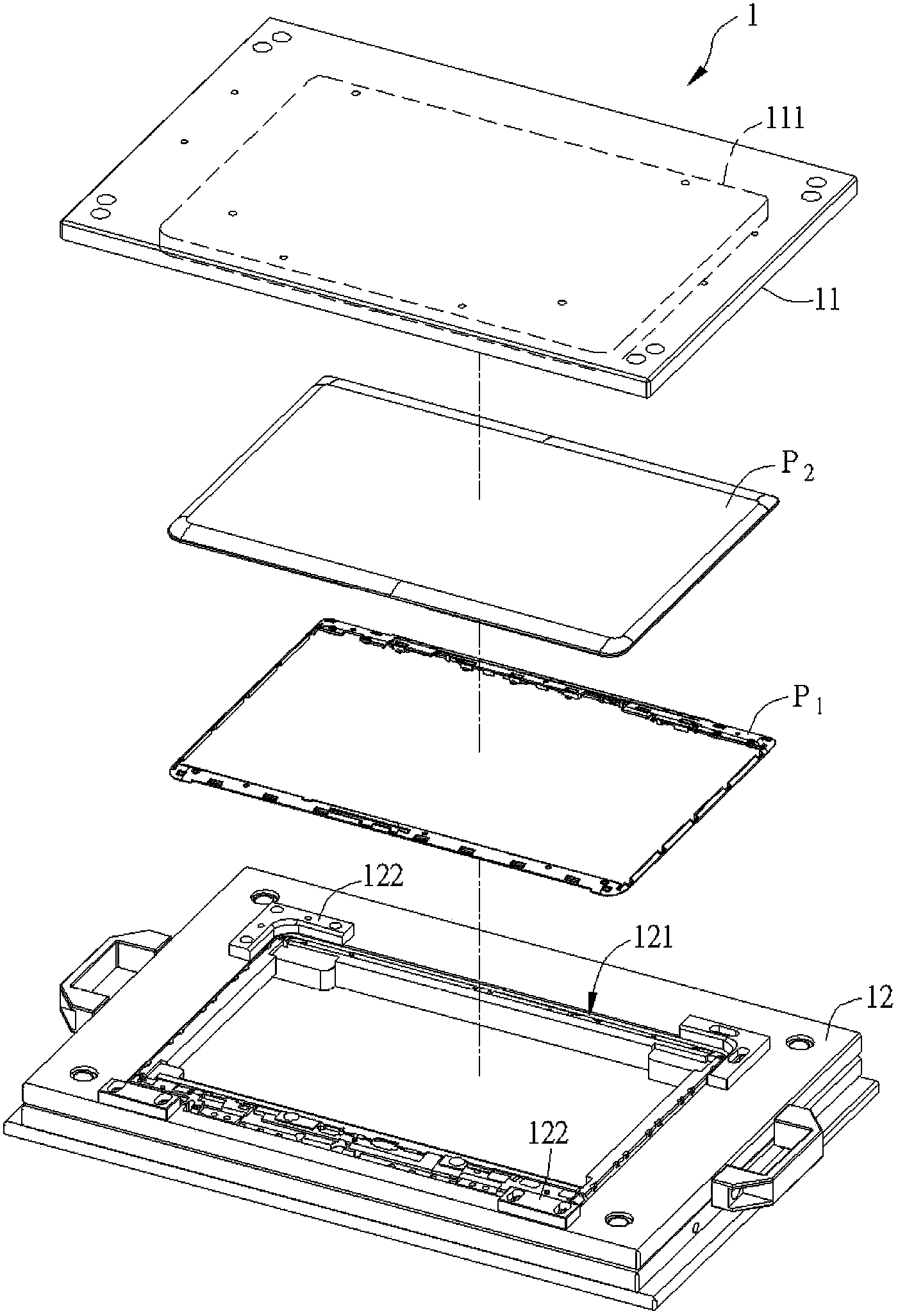

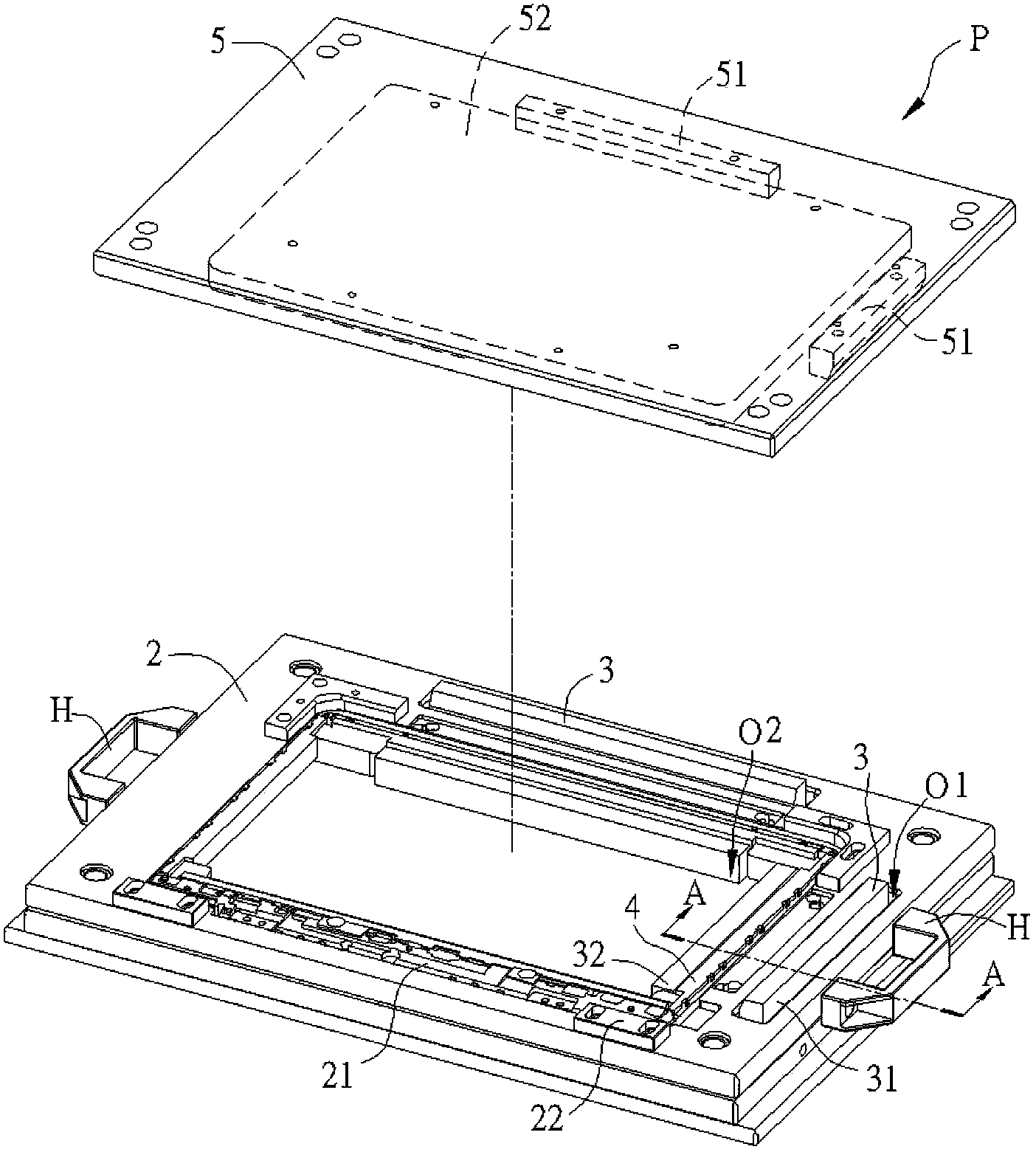

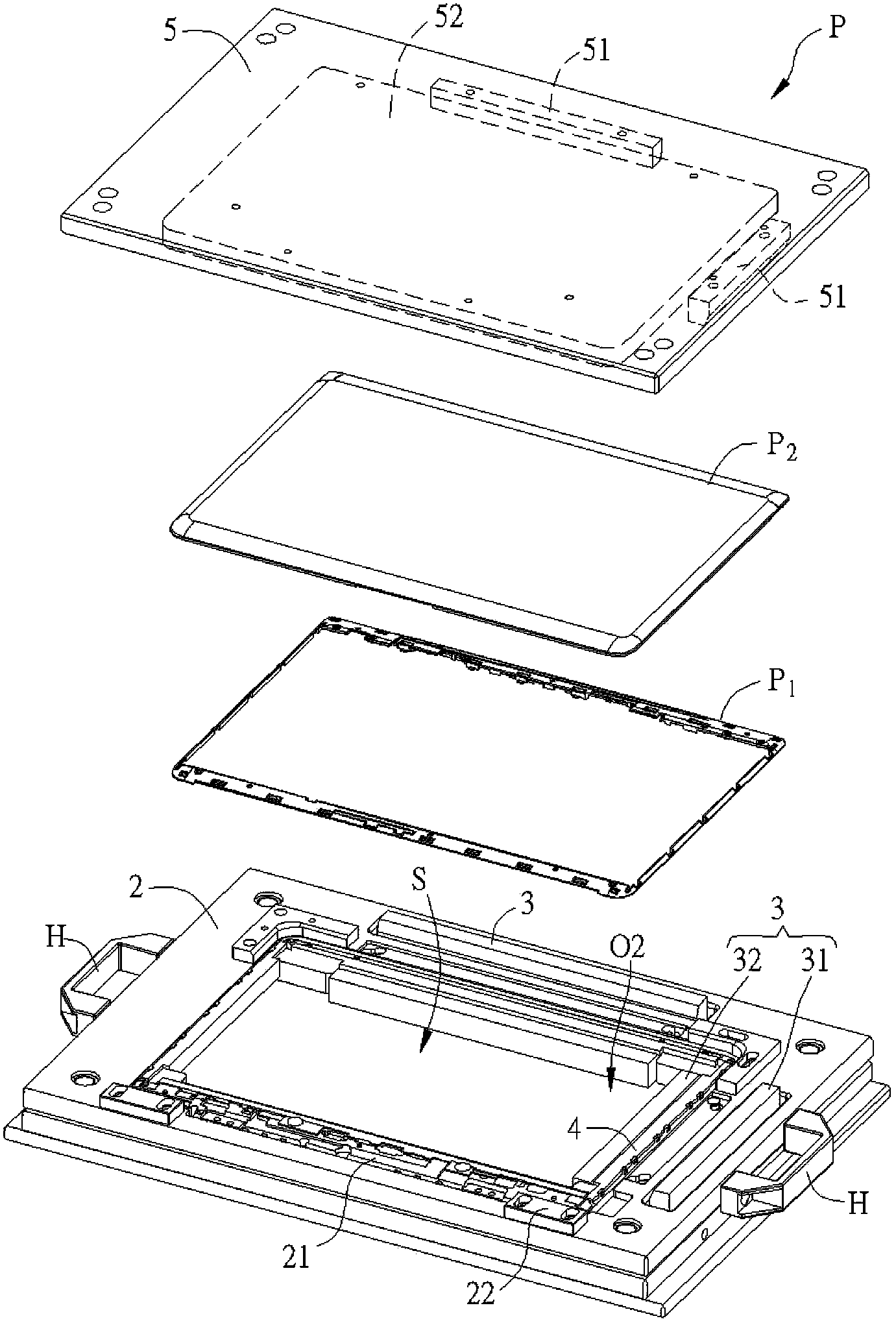

[0030] Figure 2A It is a schematic diagram of a pressing device according to the first embodiment of the present invention, Figure 2B for Figure 2A The schematic diagram of the press-fitting device before accommodating the first workpiece and the second workpiece is shown. Please also refer to Figure 2A and Figure 2B As shown, a pressing device P of the first embodiment of the present invention is used to press the first workpiece P 1 and the second workpiece P 2 ( Figure 2B ), and the pressing device P includes a base 2 , at least two sliding blocks 3 , at least two movable positioning blocks 4 and a pressing member 5 . Wherein, the pressing device P can be used for pressing two workpieces that need to be bonded in any electronic device. He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com