Universal electronic product assembling platform and assembling process thereof

An electronic product and universal technology, applied in the field of automation, can solve the problems of poor versatility of automated assembly equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

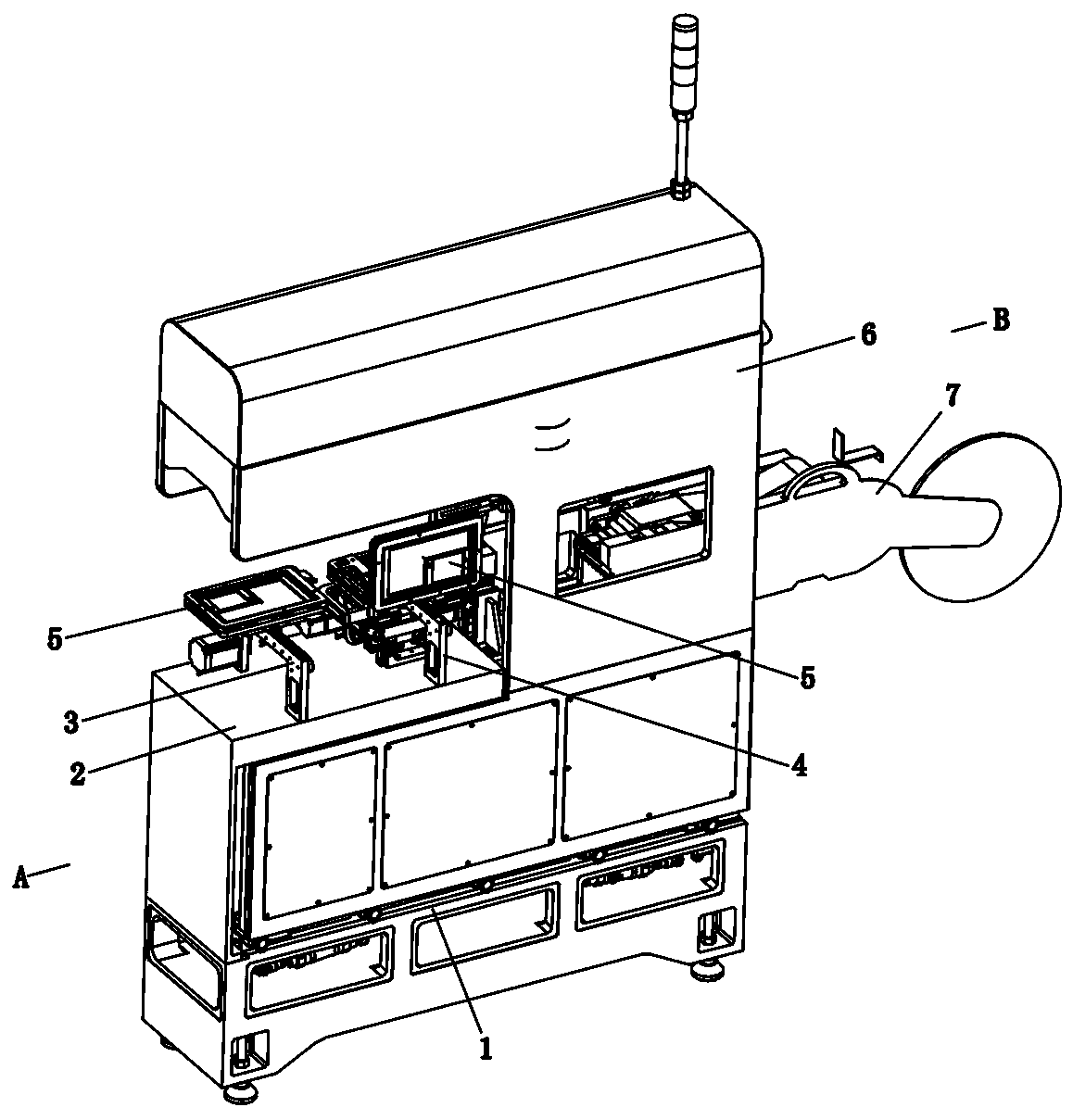

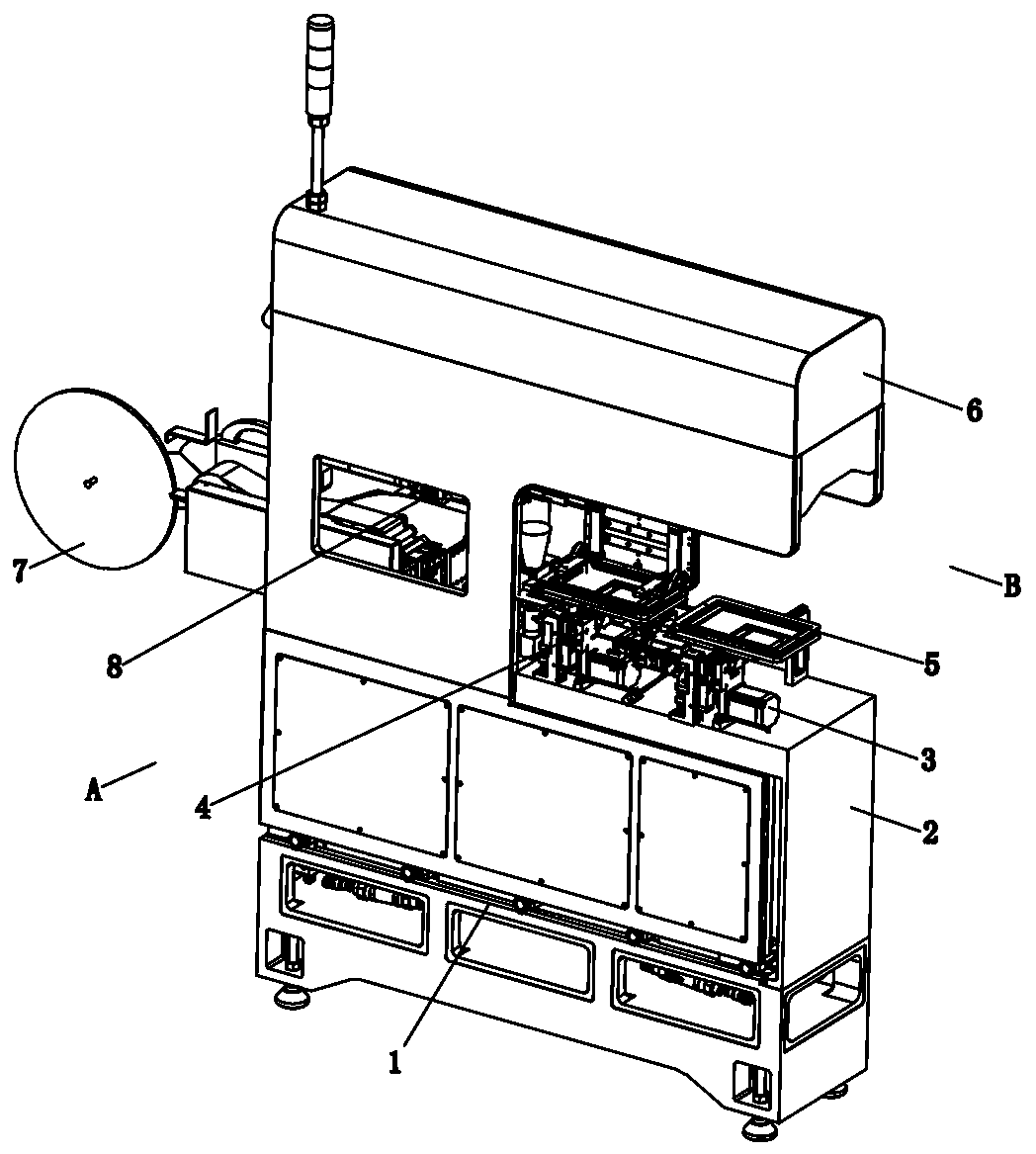

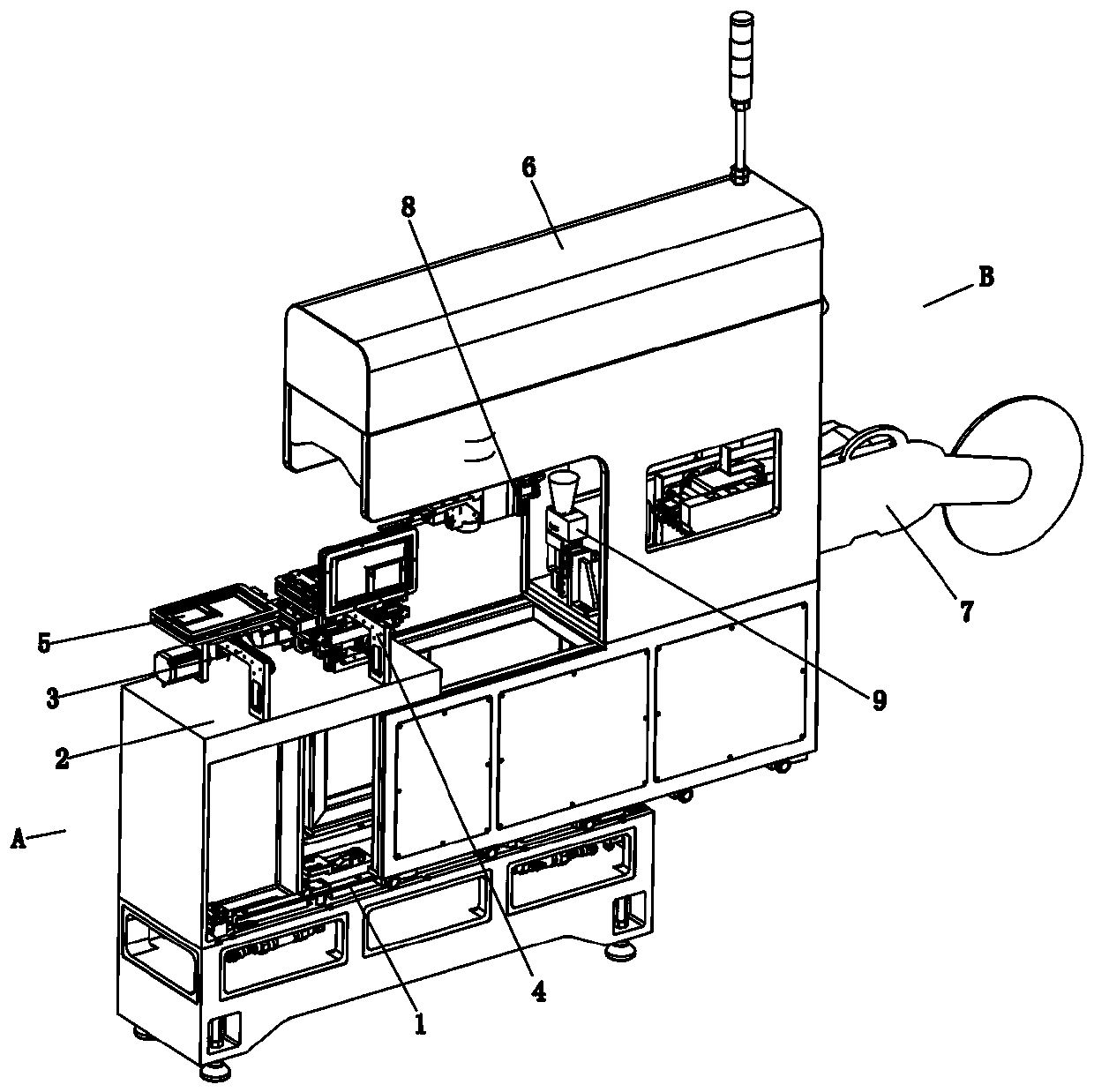

[0077] The present invention will be further described below in conjunction with accompanying drawing:

[0078] like Figure 1 to Figure 33As shown, the technical solution adopted by the present invention is as follows: a general-purpose electronic product assembly platform, including a platform part A and an assembly part B, and the platform part A and the assembly part B are inserted and installed with each other along the horizontal direction to form an overall structure, wherein the above-mentioned The platform part A includes an assembly component 1, a support platform 2, a feeding pull body 3, a platform component 4 and a jig 5; the above-mentioned assembly component 1 is arranged horizontally, and the support platform 2 is arranged on one side of the assembly component 1, and extends to Above the assembly assembly 1, a horizontal support surface is formed; the above-mentioned feeding pull body 3 includes two strips, and the two feed pull bodies 3 are arranged on the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com