Positioning device for garment cutting

A positioning device and clothing technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of high labor intensity, cumbersome operation steps, cutting size errors, etc., and achieve reduced labor intensity, straight and tidy edges, and convenient packaging. The effect of edge seam treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

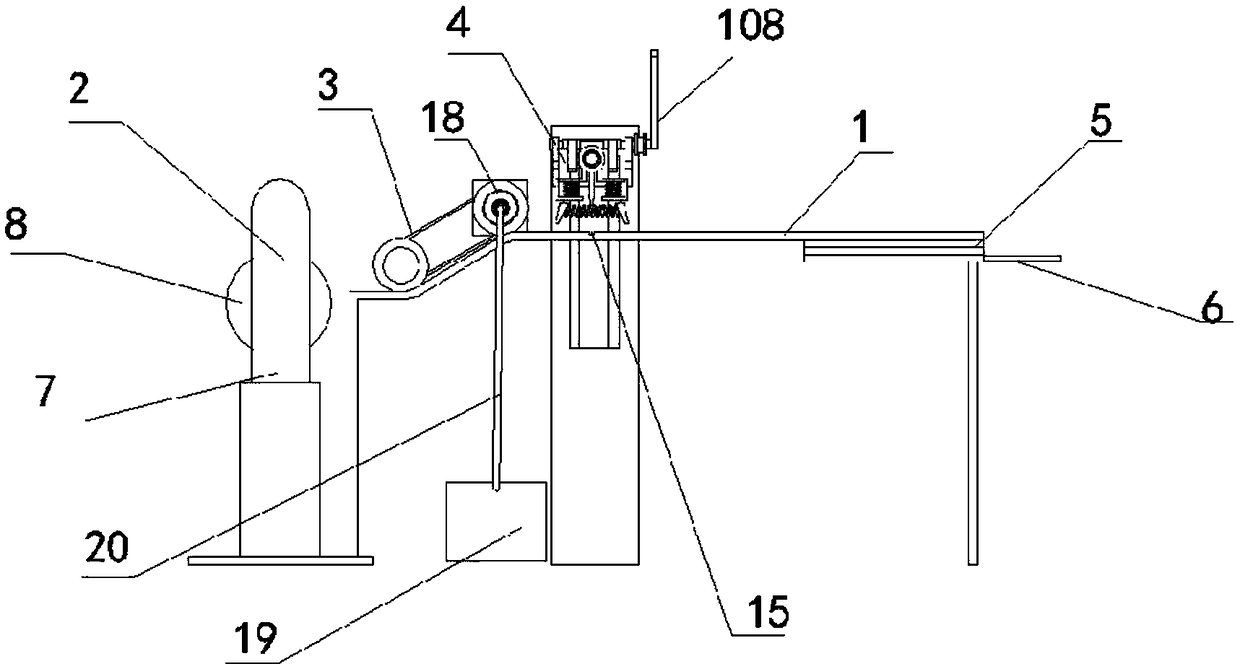

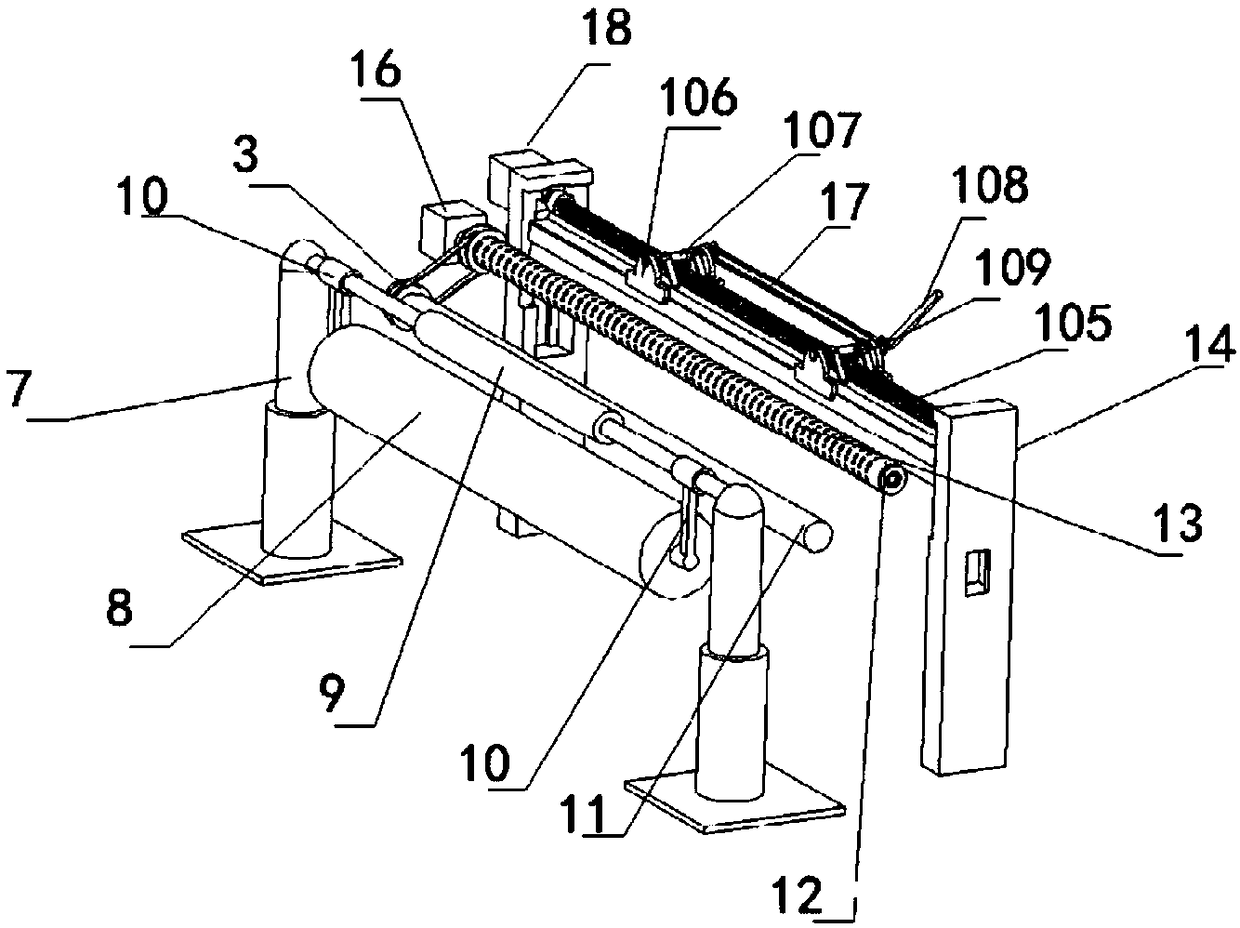

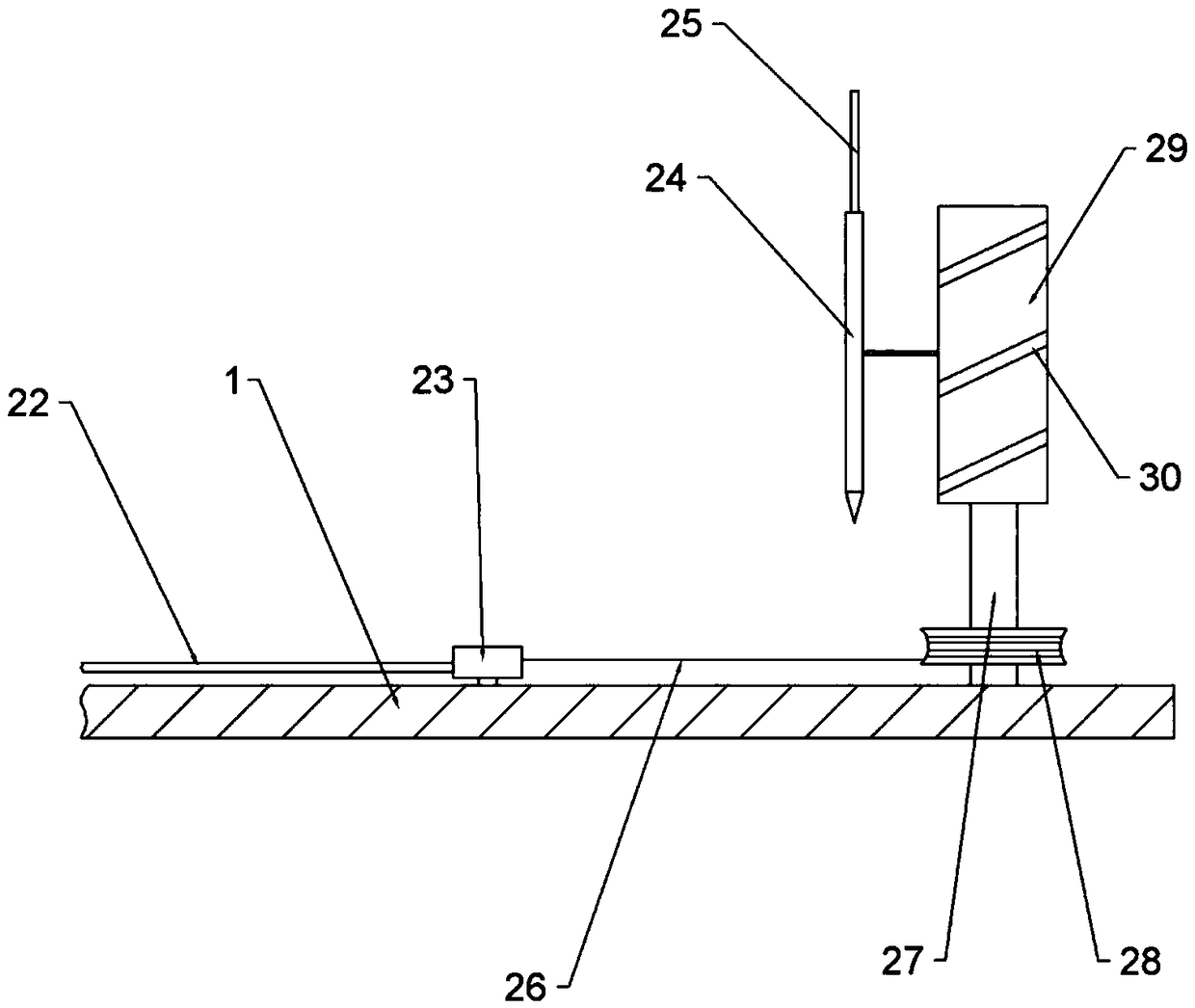

[0017] The reference signs in the accompanying drawings of the specification include: frame 1, lifting machine 2, ironing roller group 3, cutting part 4, folding plate 5, handrail 6, hydraulic cylinder 7, cloth tube 8, fixed frame 9, fixed rod 10 , first roller 12, second roller 11, through hole 13, electric lifting table 14, knife groove 15, first motor 16, sprocket 17, second motor 18, steam generator 19, hose 20, ironing device 21. Push plate 101, cutting plate 102, slotting 103, cutting knife 104, screw rod 105, fixed plate 106, rotating shaft 107, joystick 108, pre-compression rod 109, cloth 22, clip 23, positioning rod 24, bracket 25, Nylon rope 26, rotating shaft 27, bobbin 28, rotating drum 29, chute 30.

[0018] The embodiment is basically as Figure 1 to Figure 5 As shown, a positioning device for garment cutting includes a frame 1, a lifting machine 2, an iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com