High-speed feed and discharge system

A high-speed technology of feeding and discharging materials, applied in the field of freeze dryers, can solve the problems of low feeding efficiency, affecting production efficiency, bottle body collision, etc., to reduce the running speed, improve the efficiency of bottle sorting, and overcome the effect of liquid hanging on the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

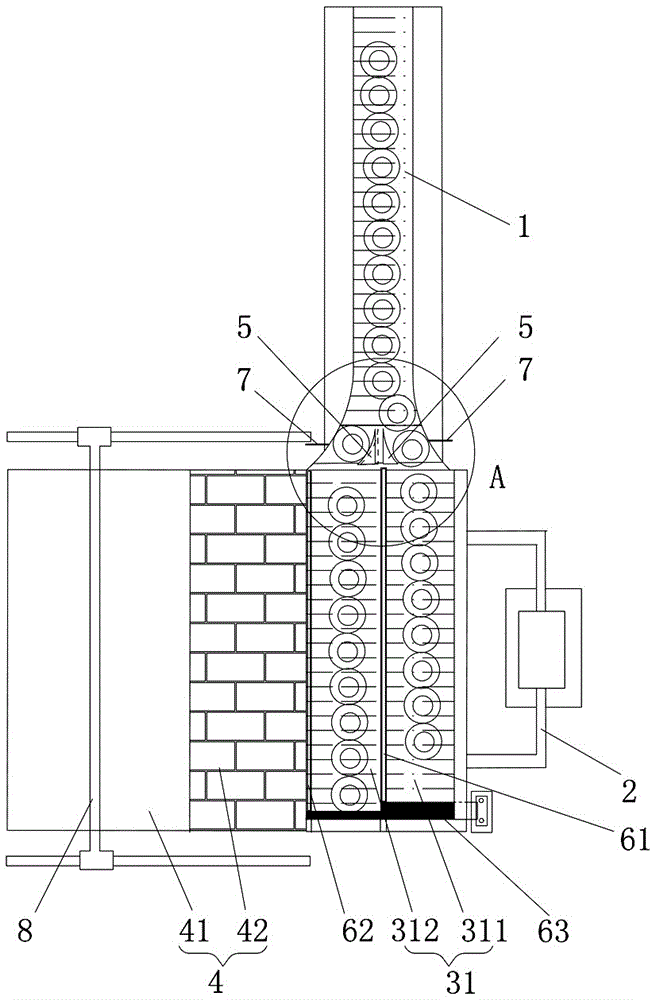

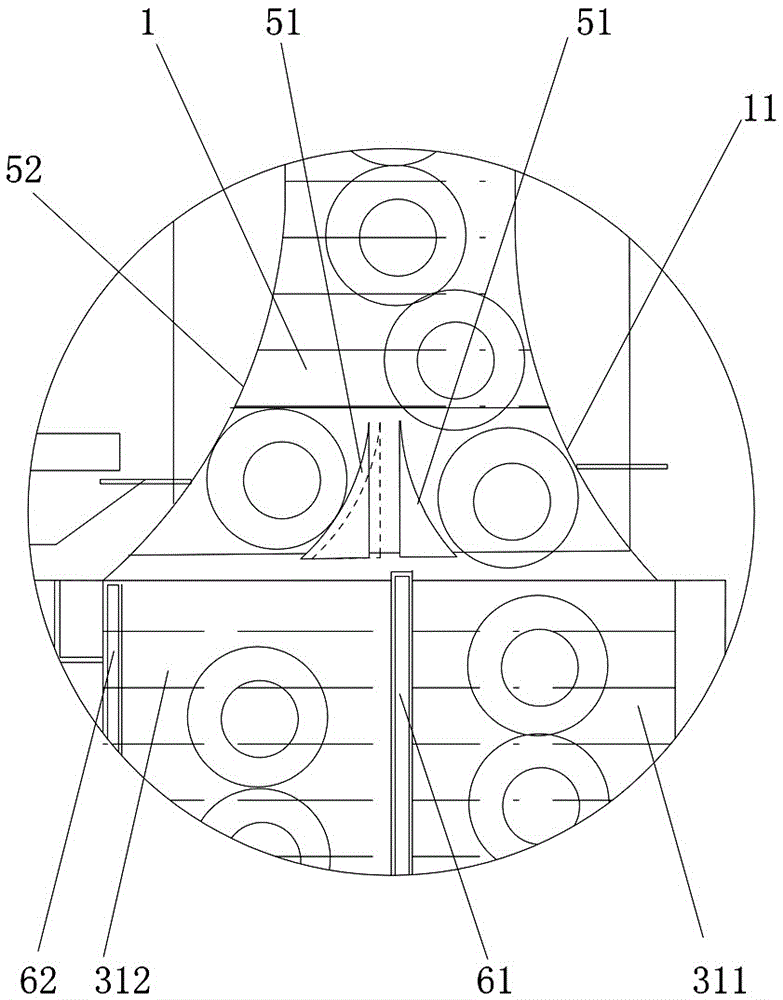

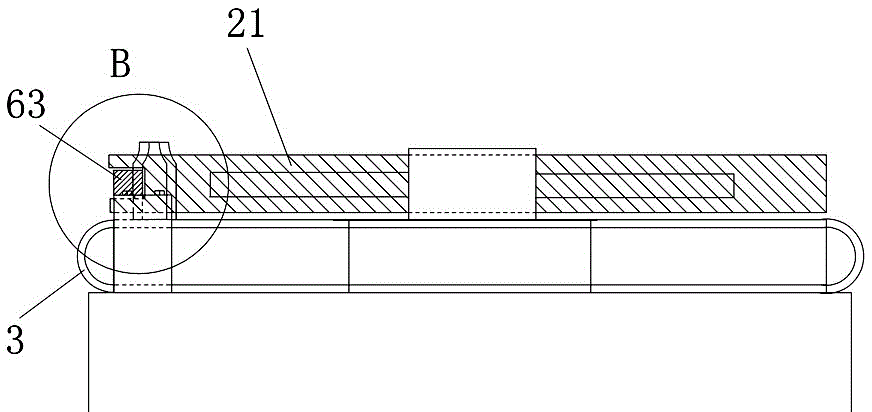

[0024] Figure 1 to Figure 4 An embodiment of the high-speed feeding and discharging system of the present invention is shown, the high-speed feeding and discharging system includes a feeding mesh belt 1, a pushing device 2 and a material collecting device 4, and the feeding system for high-speed feeding and discharging also includes a bottle unscrambling mesh belt 3. At least two bottle unscrambling passages 31 arranged side by side are formed on the bottle unscrambling mesh belt 3. The bottle inlets of each bottle unscrambling passage 31 are docked with the bottle outlets of the feeding mesh belt 1, and each joint is equipped with a guide The bottle body on the feeding mesh belt 1 is sent to the corresponding bottle unscrambling channel, and the bottle clamping device 5 that controls the opening and closing of the bottle unscramblin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com