Full-automatic bottle collator

A fully automatic, bottle unscrambler technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., to achieve the effect of improving bottle unscrambling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

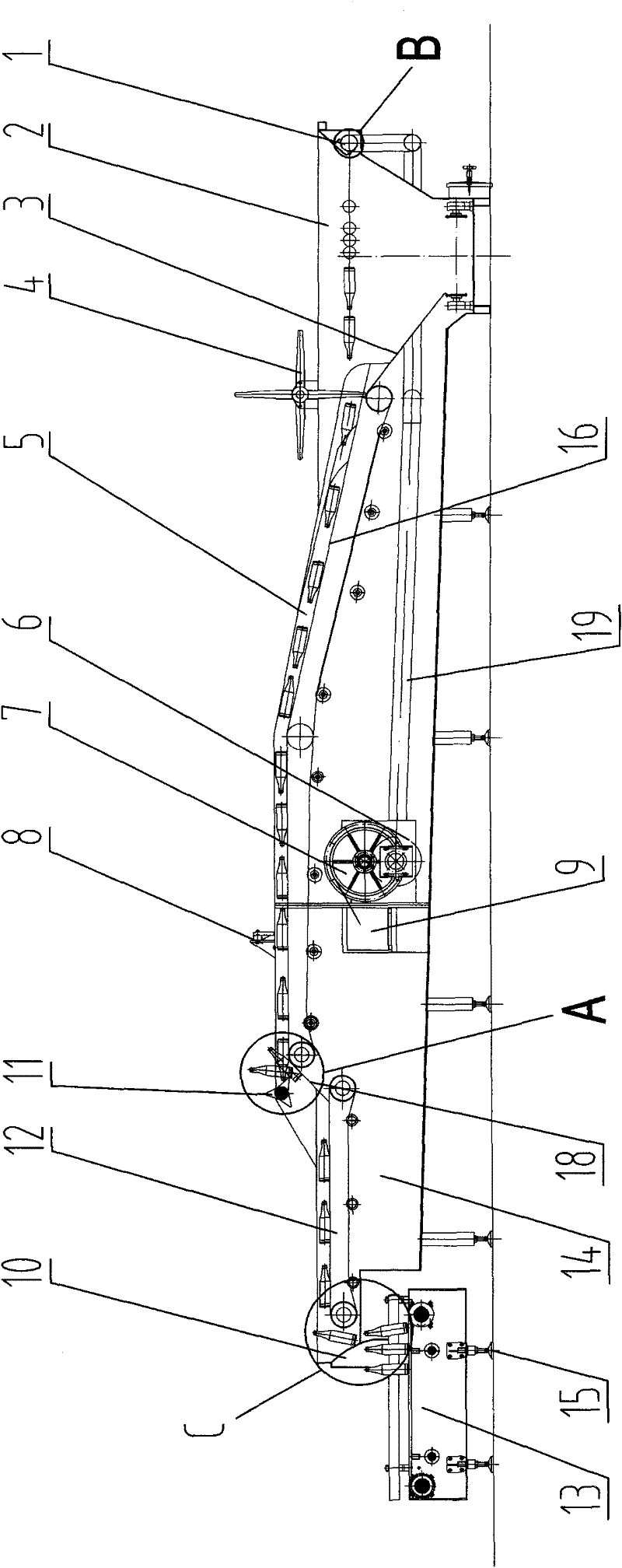

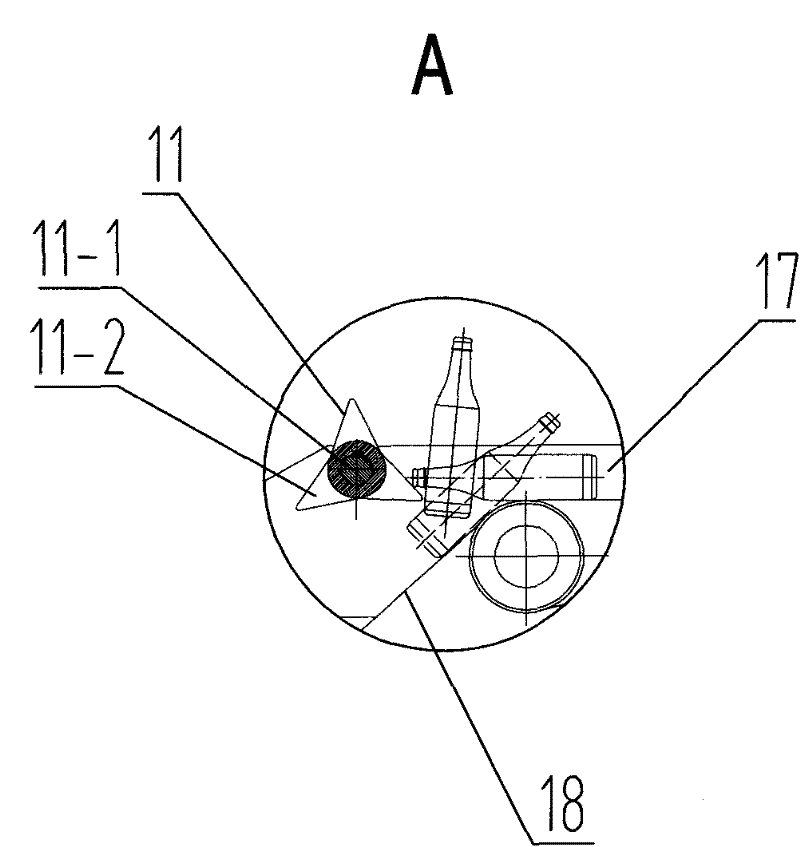

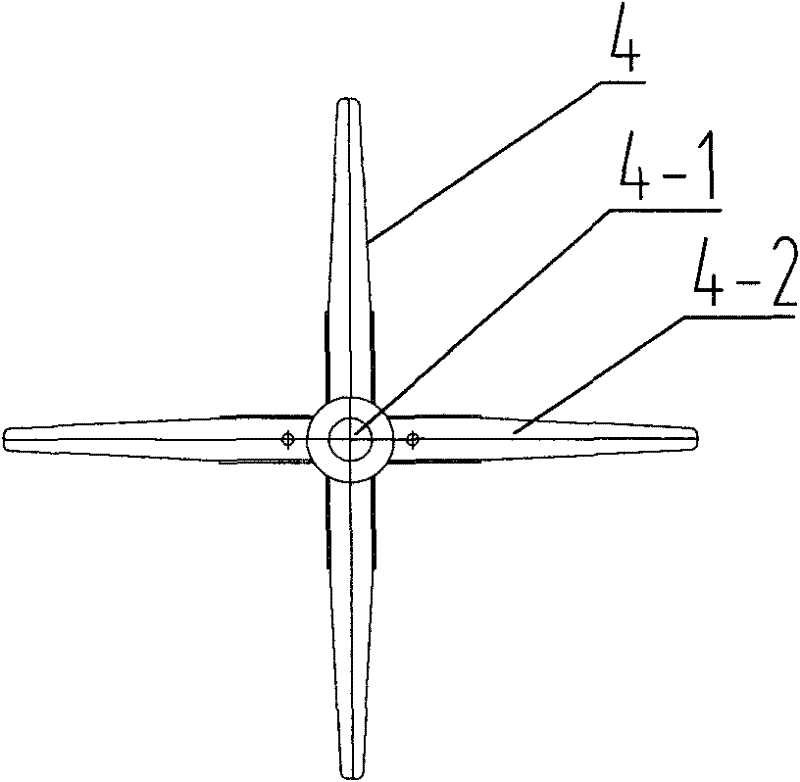

[0025] Such as figure 1 , 2 As shown, it is a fully automatic bottle unscrambler, including a frame 14 and a water tank 2. The rear end of the water tank 2 is provided with a surfing device 1 facing forward in the water outlet direction. The conveying device 16, the second conveying device 12 and the third conveying device 13, the first conveying device 16 is arranged obliquely in the water tank 2 along the length direction of the water tank 2, and the front end of the first conveying device 16 is higher than the rear end. The front end of the first conveying device 16 is placed horizontally, the second conveying device 12 is arranged below the front end of the first conveying device 16 , and the front end of the first conveying device 16 is connected with the rear end of the second conveying device 12 through a swash plate 18 . Below the front end of the second conveying device 12, the third conveying device 13 is arranged. On the first conveying device 16 and the second con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com